Degradable plastic and preparation method thereof

A technology for degrading plastics and degrading resins, applied in the field of degradable plastics and their preparation, can solve problems such as insufficient degradation of plastics, and achieve the effects of increasing surface/volume ratio, good biodegradability, and complete degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

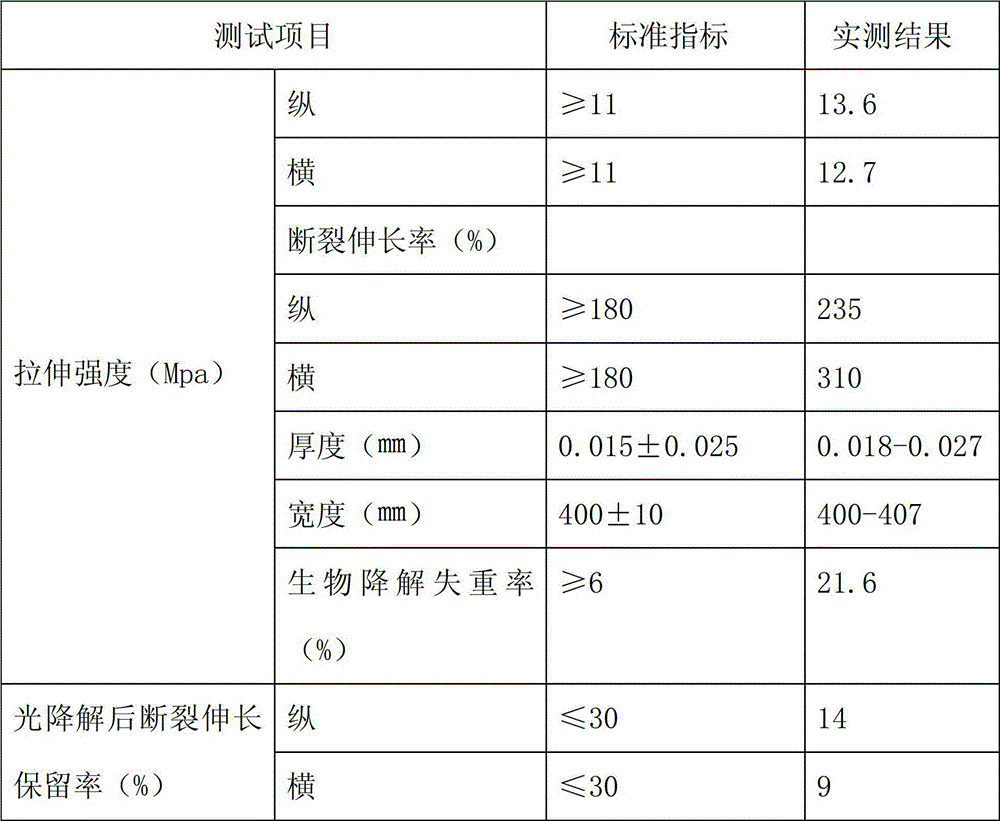

Image

Examples

Embodiment

[0031] Weigh the corresponding raw materials according to the following weight percentages:

[0032] Superfine starch: 30;

[0033] Superfine vegetable powder: 15;

[0034] Sorbitol: 5 (plasticizer);

[0035] Glycerin: 3 (plasticizer);

[0036] EAA ethylene-acrylic acid copolymer: 18 (synthetic degradable resin);

[0037] Soybean oil: 1 (compatibilizer);

[0038] White oil: 0.5 (compatibilizer);

[0039] Stearic acid: 0.6 (pro-oxidant);

[0040] Calcium stearate: 0.7 (lubricant);

[0041] Aluminate coupling agent: 1.47 (compatibilizer);

[0042] Oleic acid: 1.0 (pro-oxidant);

[0043] Iron diethyldithiocarbamate: 0.06 (photosensitizer);

[0044] Polyethylene wax: 0.8 (lubricant);

[0045] Manganese acetylacetonate: 0.8 (heat sensitive agent);

[0046] 2,6-di-tert-4-methyl-p-cresol: 0.07 (degradation control agent);

[0047] Linear low density polyethylene: 7 (synthetic resin);

[0048] HDPE: 8 (synthetic resin);

[0049] Low-density polyethylene: 7 (synthetic res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com