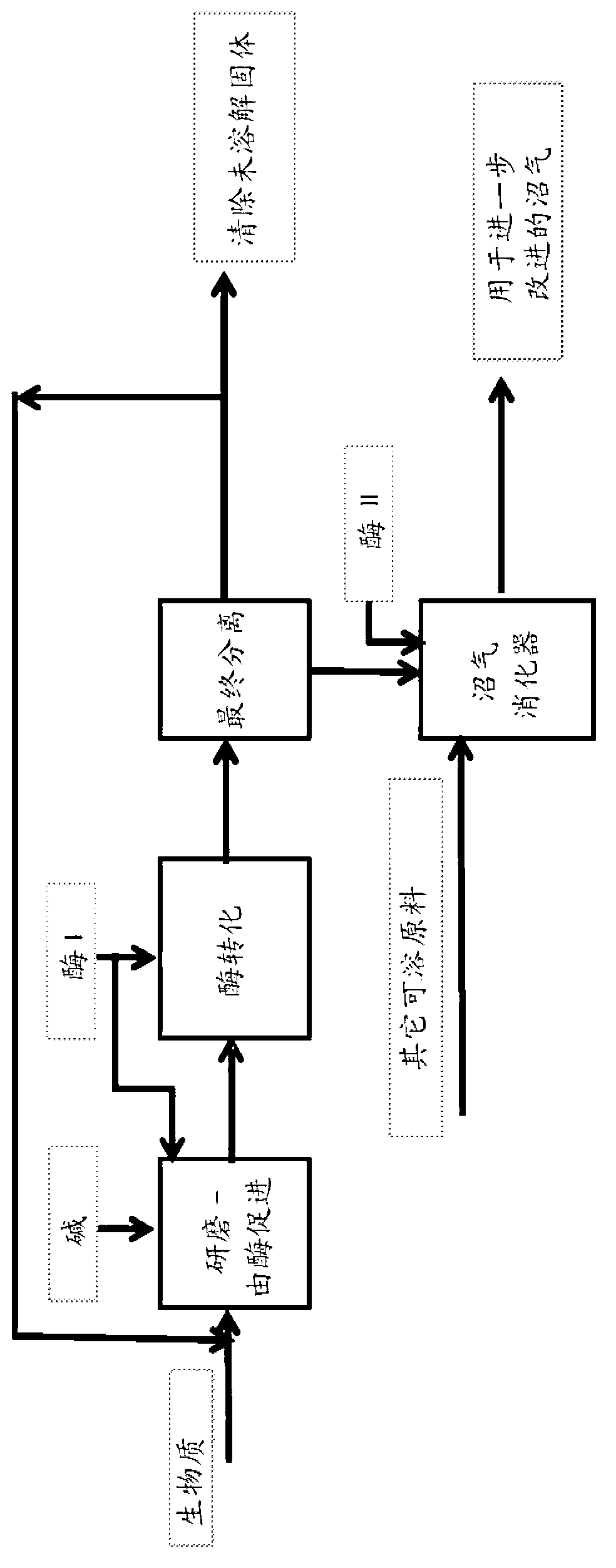

Biogas production process with enzymatic pre-treatment

A technology of enzyme pretreatment and production method, which is applied in the direction of biofuel, waste fuel, fermentation, etc., can solve the problem of not being transformed, and achieve the effect of high productivity and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

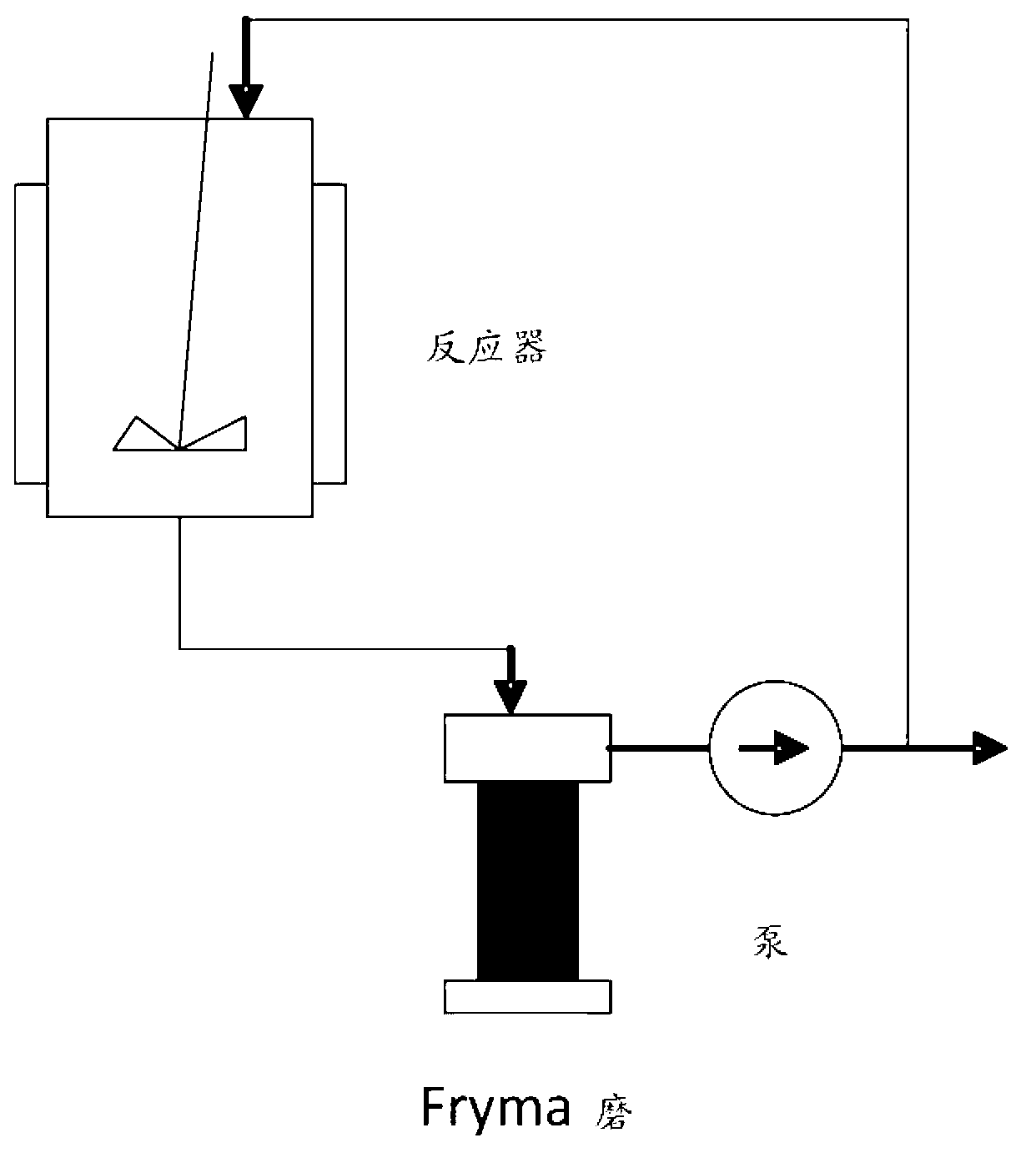

Method used

Image

Examples

Embodiment 1

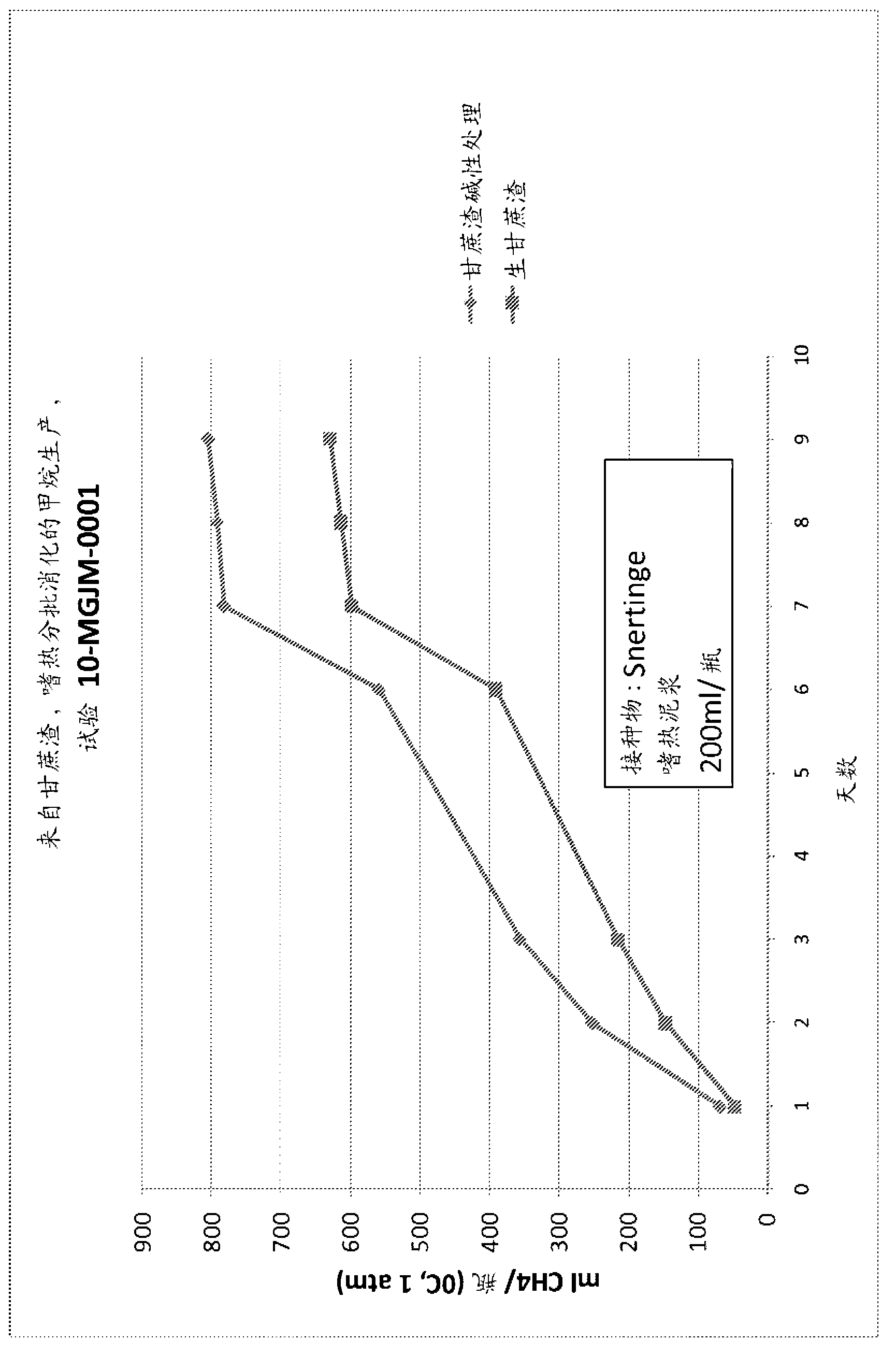

[0233] Example 1: Enzymatic liquefaction of biomass raw material for biogas production

[0234] The washing process is carried out under alkaline conditions, the purpose of which is to remove the soluble fraction of lignin and to swell the biomass material. Alkaline soluble compounds removed during washing include unwanted inhibitory substances to microorganisms and enzymes used in subsequent processing. During or after washing, cell wall degrading enzymes are used to enzymatically liquefy the biomass material and open up the recalcitrant structure of the biomass, which allows easier digestion of cellulose and other fermentable materials.

[0235] The main structural polysaccharides of lignocellulosic materials are generally composed of cellulose, hemicellulose (rich in neutral sugars), pectin materials containing D-galacturonic acid residues and mannan, which in different plant species It exists in combination with lignin in different proportions.

[0236] 1. Grind 200 g of...

Embodiment 2

[0260] Example 2: Enzymatic Digestion of Wheat Straw Biomass Material

[0261] 1. Grind 200 g of straw material for 2 minutes using a coffee grinder Bosch KM13 (E nr: MKM 6003FD 9512). A slurry of ground straw was prepared using 2000 mL of 1.2% NaOH with slow stirring at room temperature for 2 hours.

[0262] 2. Pour the material on a separating sieve with a mesh size of 0.295 mm, wash the material on the sieve with about 15 L of tap water and press with a spoon.

[0263] 3. Measure the pH of the filter cake to 8.1 using a WTW pH meter.

[0264] 4. A slurry 2000 g with 6.27% w / w dry matter was prepared and divided into 4 reactors, each containing 500 g, and the reactors were placed in a 50°C water bath.

[0265] 5. Table 1 above shows the activity of the enzyme products used in the test.

[0266] 6. The calculated enzyme dosage per gram of washed biomass shown in Table 6 was used for pretreatment.

[0267] 7. The hydrolysis reaction was carried out using the doses shown in...

Embodiment 3

[0282] Example 3: Enzymatic Digestion of Wheat Straw Biomass Material

[0283] 1. Grind 200 g of straw material for 2 minutes using a coffee grinder Bosch KM13 (E nr: MKM 6003FD 9512). A slurry of ground straw was prepared using 2000 mL of 1.2% NaOH with slow stirring at room temperature for 2 hours.

[0284] 2. Pour the material on a separation sieve with a mesh size of 0.295 mm, wash the material on the sieve with about 30 L of tap water and press with a spoon.

[0285] 3. Measure the pH of the filter cake to 7.8 using a WTW pH meter.

[0286]4. A slurry 2000 g with 6.26% w / w dry matter was prepared and divided into 4 reactors, each containing 500 g, and the reactors were placed in a 50°C water bath.

[0287] 5. Table 1 above shows the activity of the enzyme products used in the test.

[0288] 6. The calculated enzyme dosage per gram of washed biomass shown in Table 11 was used for hydrolysis pretreatment in each reactor.

[0289] 7. To verify by analysis that the enzyma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com