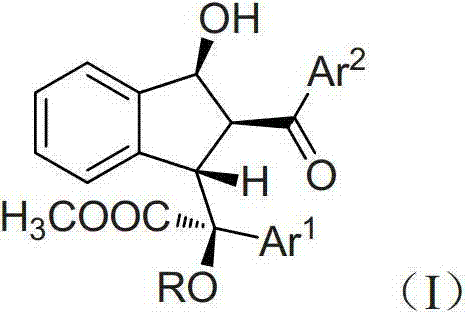

Preparation method of multi-substituted indanol derivatives

A derivative and multi-substitution technology, applied in the field of pharmaceutical synthetic chemistry, can solve the problems of lack of diversity in product structure, narrow substrate applicability, harsh reaction conditions, etc., and achieve the effects of high selectivity, low cost, and simple synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

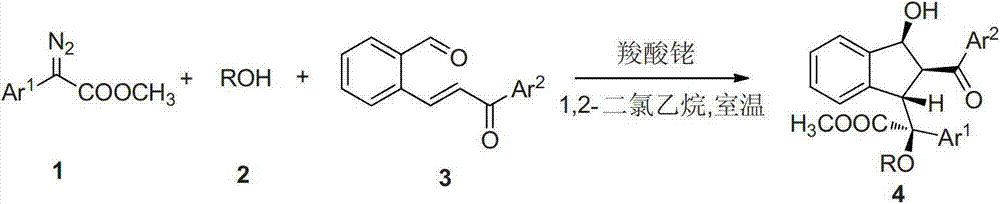

Method used

Image

Examples

preparation example Construction

[0034] Its preparation method comprises the following steps:

[0035] First weigh the diazo compound 1a in molar ratio: o-formyl chalcone 3a: alcohol 2a: metal catalyst (rhodium acetate) = 1.2: 1.0: 1.2: 0.02, o-formyl chalcone, alcohol, rhodium acetate, and absorbent Molecular sieve and organic solvent are added in the reaction bottle, and the water-absorbing agent The addition amount of the molecular sieve is 2-5 g / mmol o-formyl chalcone, and the addition amount of the organic solvent is 25-30 ml / mmol o-formyl chalcone. Next, the diazo is dissolved in an organic solvent to obtain a diazo solution, and the amount of the organic solvent used for dissolving the diazo is 25-30 ml / mmol of imine. Then, at room temperature, the diazonium solution was added dropwise into the reaction flask through a peristaltic pump, and the dropwise addition was completed in 2 hours. After continuing to stir for 1 hour, the reaction was completed, and the solvent was removed by rotary evaporati...

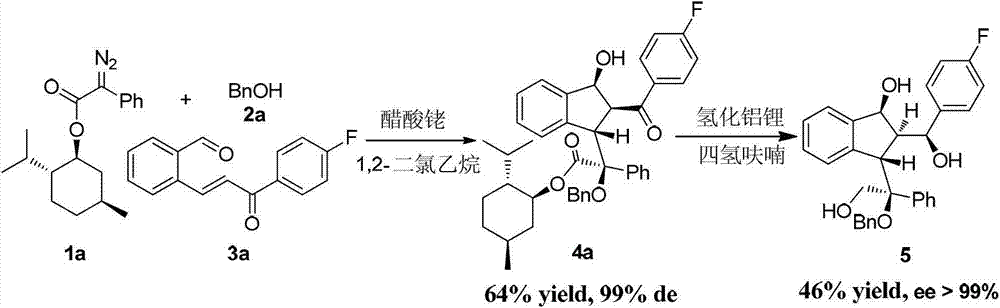

Embodiment 1

[0039]

[0040]Weigh (E)-2-(3-oxa-3-phenylpropenyl)benzaldehyde (0.20mmol), rhodium acetate (1.77mg, 0.004mmol), benzyl alcohol (25.9mg, 0.24mmol), Molecular sieves (100 mg) were placed in a small test tube reactor and 5.6 ml of redistilled 1,2-dichloroethane was added at room temperature. Weigh methyl phenyldiazoacetate (0.24mmol) and dissolve it in 2.8ml redistilled 1,2-dichloroethane, and inject it into the reaction system through a peristaltic pump for 2 hours, and continue to stir at room temperature for 1 hour after the injection is completed. , filtered, and the filtrate was removed by rotary evaporation at 20-50°C to remove the solvent, and then separated by column chromatography (eluent: ethyl acetate: petroleum ether = 1: 10-1: 5) to obtain diastereoselective Pure product of polysubstituted indenol derivatives. Yield 72%, d.r. value greater than 20:1.

[0041] 1 H NMR (500MHz, CDCl 3 , 25°C, TMS): δ=2.40(d, J(H,H)=9.8Hz, 1H), 3.57(s, 3H), 4.31(d, J(H,H)=11.6H...

Embodiment 2

[0043]

[0044] Weigh (E)-2-(3-oxa-3-phenylpropenyl)benzaldehyde (0.20mmol), bis(hexafluoroacetylacetonate)copper(II) (1.91mg, 0.004mmol), benzyl alcohol (25.9 mg, 0.24 mmol), Molecular sieves (100 mg) were placed in a small test tube reactor and 5.6 ml of redistilled 1,2-dichloroethane was added at room temperature. Weigh methyl phenyldiazoacetate (0.24mmol) and dissolve it in 2.8ml redistilled 1,2-dichloroethane, and inject it into the reaction system through a peristaltic pump for 2 hours, and continue to stir at room temperature for 1 hour after the injection is completed. , filtered, and the filtrate was evaporated at 40 ° C to remove the solvent, and then separated by column chromatography (eluent: ethyl acetate: petroleum ether = 1: 10-1: 5) to obtain a multi-substituted compound with high diastereoselectivity. Pure products of indenol derivatives. Yield 72%, d.r. value greater than 20:1.

[0045] 1 H NMR (500MHz, CDCl 3 , 25°C, TMS): δ=2.40(d, J(H,H)=9.8Hz, 1H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com