Method for breaking algae cells

A technology for algal cells and algal liquid, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, and microbial dissolution, etc., can solve the problems of limited application scope, difficult operation, and many steps, and achieves good wall breaking effect and equipment. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

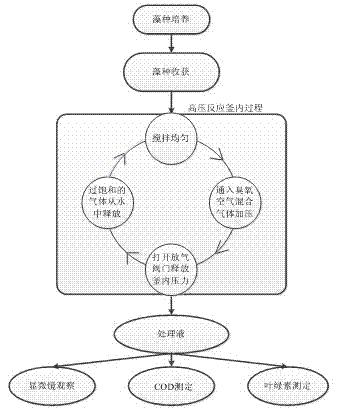

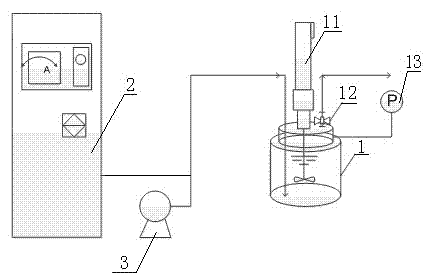

[0028] A method for breaking algae cells, specifically comprising the following steps:

[0029] (1) Measure 200 ml of harvested algae liquid into a 1 L autoclave, and stir for 5 min at 120-130 r / min;

[0030] (2) Turn on the ozone generator and air compressor, and pass the mixed gas composed of ozone and air with a volume ratio of 1:150 of ozone and air into the high-pressure reactor at a total flow rate of 2 L / min, and continue Stir the algae liquid at a constant speed of 120-130 r / min, so that the incoming ozone, air and algae liquid are evenly mixed;

[0031] (3) Control the pressure of the high-pressure reactor to 0.6 MPa. When it reaches 0.6 MPa, maintain it for 1 to 2 s, open the exhaust valve of the high-pressure reactor to reduce the pressure to normal pressure, and then increase the pressure to 0.6 MPa. When it reaches 0.6 Mpa, the exhaust valve of the high-pressure reactor is opened again to reduce the pressure to normal pressure, and the broken algae cells are obta...

Embodiment 2

[0046] A method for breaking algae cells, specifically comprising the following steps:

[0047] (1) Measure 200 ml of the harvested chlorella solution in a 1 L autoclave, and stir for 5 min at 120-130 r / min;

[0048] (2) Turn on the ozone generator and air compressor, and pass the mixed gas composed of ozone and air with a volume ratio of 1:150 of ozone and air into the high-pressure reactor at a total flow rate of 2 L / min, and continue Stir the algae liquid at a constant speed of 120-130 r / min, so that the incoming ozone, air and algae liquid are evenly mixed;

[0049] (3) Set the pressure to 0.6 MPa. When it reaches 0.6 MPa, maintain it for 1-2 s, open the exhaust valve of the high-pressure reactor to reduce the pressure to normal pressure, and then increase the pressure to 0.6 MPa. When it reaches 0.6 Mpa, open the exhaust valve of the high-pressure reaction kettle again to reduce the pressure to normal pressure, and cycle the boosting and depressurization process 80 times...

Embodiment 3

[0052] A method for breaking algae cells, specifically comprising the following steps:

[0053] (1) Measure 200 ml of the harvested chlorella solution in a 1 L autoclave, and stir for 5 min at 120-130 r / min;

[0054] (2) Turn on the ozone generator and air compressor, and pass the mixed gas composed of ozone and air with a volume ratio of 1:150 of ozone and air into the high-pressure reactor at a total flow rate of 2 L / min, and continue Stir the algae liquid at a constant speed of 120-130 r / min, so that the incoming ozone, air and algae liquid are evenly mixed;

[0055] (3) The set pressure is 0.8 MPa. When it reaches 0.8 MPa, open the exhaust valve of the high-pressure reactor to reduce the pressure to normal pressure, and then increase the pressure to 0.8 MPa. When it reaches 0.8 MPa, open the high-pressure reactor again The exhaust valve of the kettle reduces the pressure to normal pressure, and the crushed algae cells are obtained after 80 cycles of increasing and decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com