Method for preparing high k-gate dielectrics on surface of graphene by utilizing water-based atomic layer deposition technology

An atomic layer deposition, graphene surface technology, used in coatings, metal material coating processes, semiconductor/solid-state device manufacturing, etc., can solve the problems of depositing high-k gate dielectric layers, lack of thin-film dangling bonds, etc., to improve wetting. performance, improved uniformity and coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

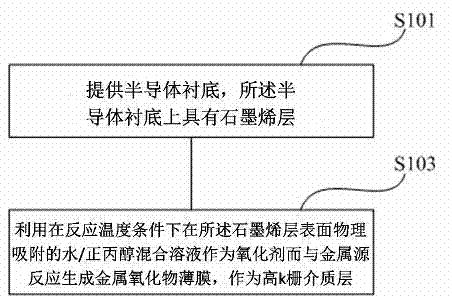

[0028] The inventors of the present invention have found that in the prior art, the oxide gate dielectric layer prepared on the surface of graphene has problems such as poor uniformity and coverage or damage to the crystal structure of graphene, which affects subsequent products (such as graphene-based field effect transistor) device performance.

[0029] Therefore, in the case of graphene-based field-effect transistors, in order to prevent the generation of the above-mentioned defects, the inventors of the present invention have improved the prior art and proposed a novel preparation method for graphene-based field-effect transistors, which mainly utilizes The amphiphilic properties of n-propanol can reduce the surface tension of water physically adsorbed on the graphene surface, thereby improving the wettability between the chemical source and graphene, thereby improving the uniformity and coverage of the metal oxide film deposited on the graphene surface .

[0030] First, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com