Method for preparing dual-structure flocky ZnO-base transparent conductive thin film

A transparent conductive film and double-structure technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of adding process steps to anti-reflection films, and achieve the effects of low production cost, avoiding poor controllability, and uniform haze value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

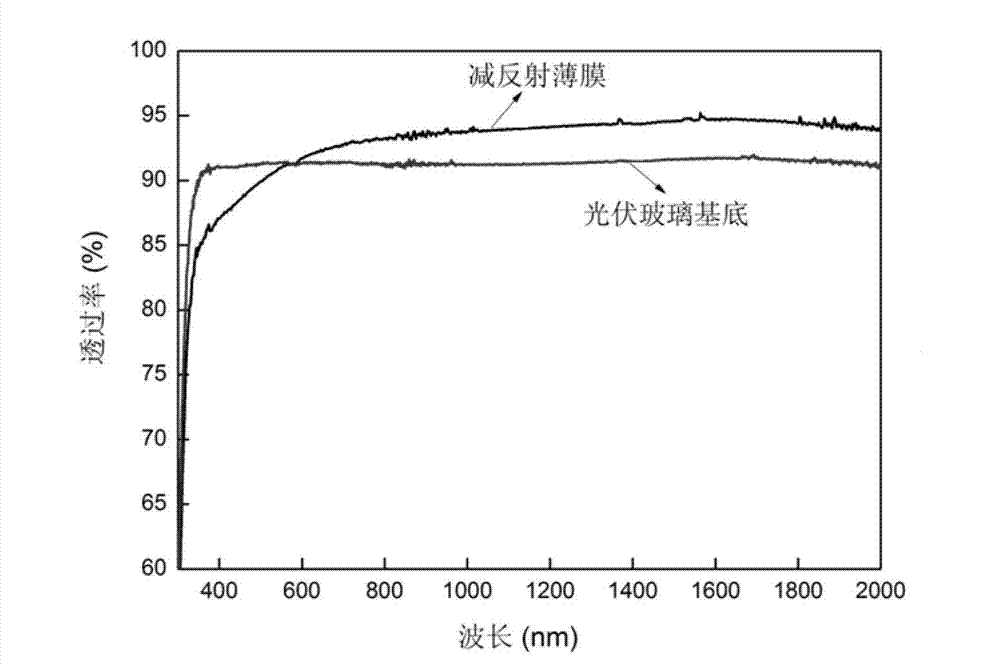

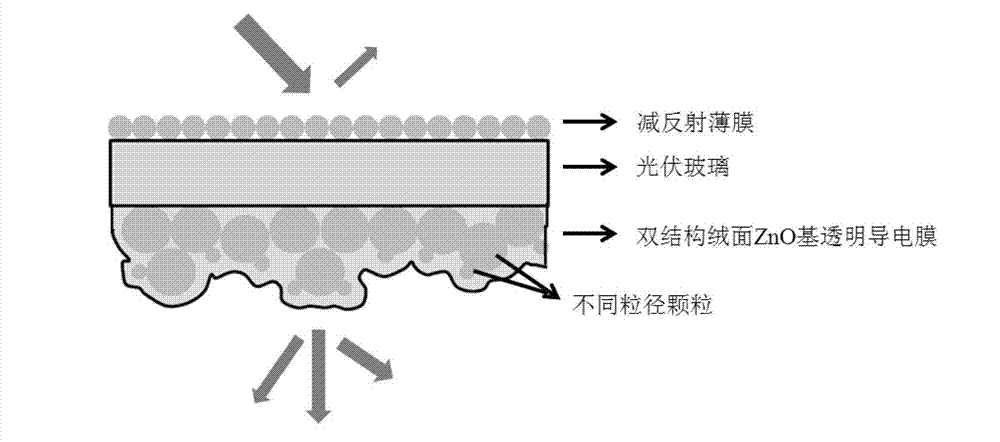

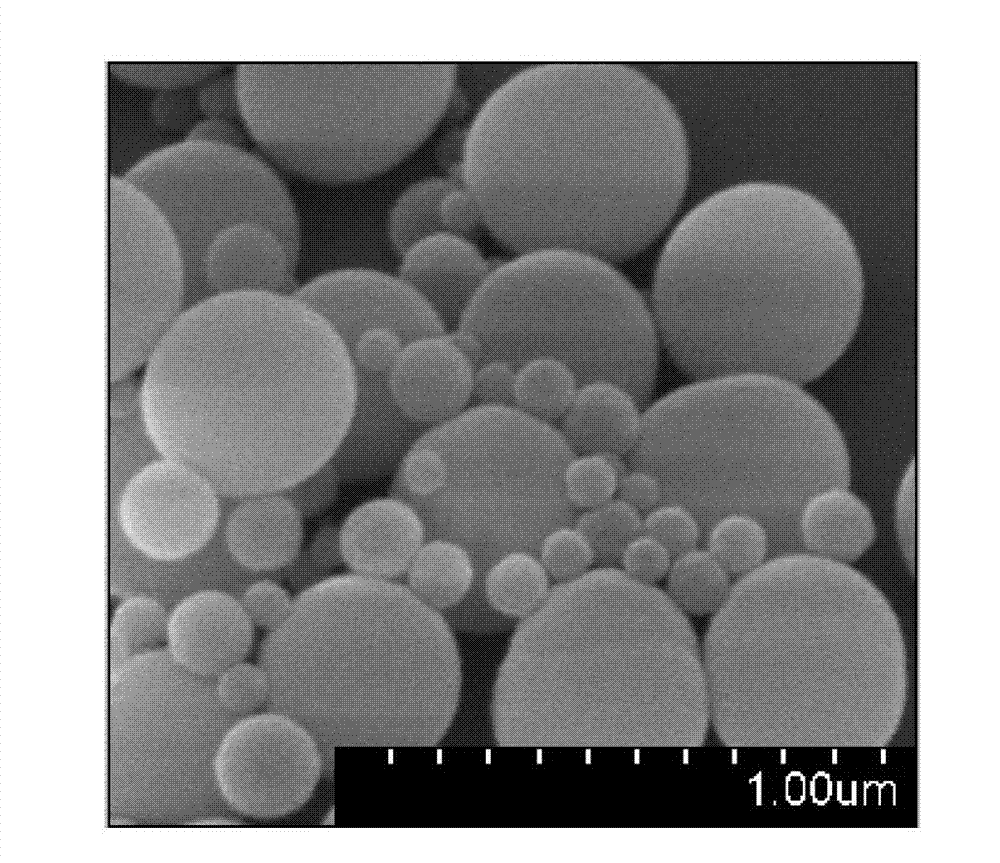

[0036] Embodiment 1: get 12mL tetraethyl orthosilicate, 40mL ammonia water, 28mL deionized water and the ethylene glycol of 125mL mix, utilize magnetic stirrer to stir 8 hours at room temperature; Then add 12mL tetraethyl orthosilicate and 2mL deionized water, continue stirring for 8 hours to obtain solution A containing large particles; mix 8mL tetraethyl orthosilicate, 14mL ammonia water, 20mL deionized water and 150mL ethanol, stir at room temperature with a magnetic stirrer for 8 hours , to obtain solution B containing small particles; the particle size difference between large particles and small particles is 250~350nm; solution A and solution B are mixed and stirred for 3 hours at a volume ratio of 1:1 to obtain mixed solution C; At a pulling speed of 1000 μm / s, the mixed solution C was coated on one side of the photovoltaic glass substrate, and then the solution B was coated on the other side of the photovoltaic glass substrate, and then dried at 200°C for 30 minutes; us...

Embodiment 2

[0037] Embodiment 2: Get 8mL orthosilicate methyl ester, 14mL ammonia water, 20mL deionized water and 150mL isopropanol to mix, utilize magnetic stirrer to stir 9 hours at room temperature; Then add 8mL orthosilicate methyl ester and 2mL to Ionized water, continue to stir for 8 hours to obtain solution A containing large particles; take 8mL tetraethyl orthosilicate, 5mL ammonia water, 12mL deionized water and 150mL isopropanol, mix at room temperature with a magnetic stirrer for 6 hours , to obtain solution B containing small particles; the particle size difference between large particles and small particles is 250~350nm; solution A and solution B are mixed and stirred for 3 hours at a volume ratio of 2:1 to obtain mixed solution C; The mixed solution C is coated on one side of the photovoltaic glass substrate at a speed of 3000r / s, and then the solution B is coated on the other side of the photovoltaic glass substrate, and then dried at 150°C for 40 minutes; using DC magnetron...

Embodiment 3

[0038] Example 3: Mix 8 mL of n-butyl titanate, 12 mL of ammonia water, 16 mL of deionized water and 150 mL of ethanol, and stir with a magnetic stirrer at room temperature for 8 hours; then add 8 mL of n-butyl titanate and 1 mL of deionized water, and continued to stir for 8 hours to obtain solution A containing large particles; take 4mL of n-butyl titanate, 6mL of ammonia water, 10mL of deionized water and 150mL of ethanol and mix them with a magnetic stirrer at room temperature for 5 hours to obtain solution A containing small Particle solution B; the particle size difference between large particles and small particles is 250~350nm; Mix solution A and solution B at a volume ratio of 1:2 and stir for 4 hours to obtain mixed solution C; apply mixed solution C by spraying On one side of the photovoltaic glass substrate, the solution B was then coated on the other side of the photovoltaic glass substrate, and then dried at 250°C for 25 minutes; One side of the glass substrate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com