Preparation method and application of a gasoline sweetening adsorbent

A technology for desulfurization and adsorbent, which is applied in the field of preparation of new gasoline desulfurization adsorbent, can solve problems such as unsatisfactory effect, and achieves the effects of easy regeneration, solving the problem of agglomeration and less environmental harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

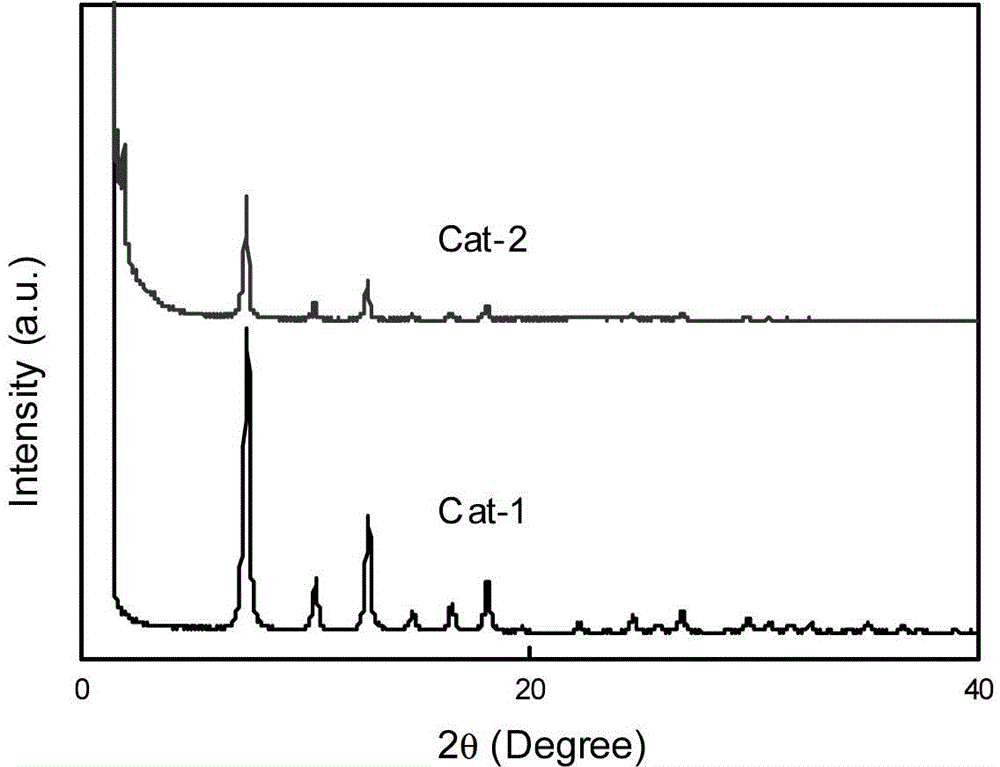

Image

Examples

Embodiment 1

[0034] This embodiment provides a gasoline sweetening sorbent, which is prepared through the following steps:

[0035]Weigh 1.1g of zinc acetate and dissolve it in 80mL of deionized water, add 0.5g of COOH-SBA-15, ultrasonically disperse for 0.5h, then add 4.1g of 2-methylimidazole, mix well, stir and age in a water bath at 40°C for 1h, turn to Put it into a polytetrafluoroethylene-lined reactor, crystallize at 140°C for 24 hours, suction filter, wash, and dry to obtain a ZIF-8 / SBA-15 complex; wherein, the synthesis process of COOH-SBA-15 is as follows: Weigh 2.0g SBA-15 and disperse it in 120mL toluene, add 5.0mL trialkoxycyanoethylsilane, reflux at 100°C for 12h, cool to room temperature, suction filter, wash with ethanol, and vacuum dry to obtain CN-SBA-15, then Weigh 1.0g CN-SBA-15 in 150mL of 48wt% H 2 8O 4 In the solution, reflux at 100°C for 4 hours, wash with deionized water until neutral, and dry to obtain the modified SBA-15, namely COOH-SBA-15;

[0036] The ZIF-8...

Embodiment 2

[0039] This embodiment provides a gasoline sweetening sorbent, which is prepared through the following steps:

[0040] Mix 50mL N,N-dimethylformamide (DMF) with 0.7g zinc nitrate, add 0.5g COOH-SBA-15 (the synthesis process is the same as in Example 1), ultrasonically disperse for 0.5h, then add 0.5g imidazole and 0.2g Mix 2-nitroimidazole evenly, stir and age at 40°C for 1h, transfer it to a polytetrafluoroethylene-lined reactor, conduct solvothermal crystallization at 100°C for 72h, filter the crystallized product, and wash , vacuum dried to obtain ZIF-68 / SBA-15;

[0041] The ZIF-68 / SBA-15 composite was tableted, crushed and sieved to obtain particles with a particle size of 20-40 mesh, and dried at 120°C to finally obtain a gasoline sweetening adsorbent, which was designated as Cat-3.

[0042] Activity Evaluation of Adsorbent for Sweetening Gasoline

[0043] The gasoline sweetening adsorbents prepared in Comparative Example 1, Example 1 and Example 2 were evaluated for ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com