Self-circulation anaerobic reactor

An anaerobic reactor and reaction chamber technology, used in anaerobic digestion treatment, waste fuel and other directions, can solve the problems of high viscosity, pollution, wet grains and filter cake yield of dried potato alcoholic grains, etc., and achieve particle pollution. High mud activity, good mass transfer effect and high biogas purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

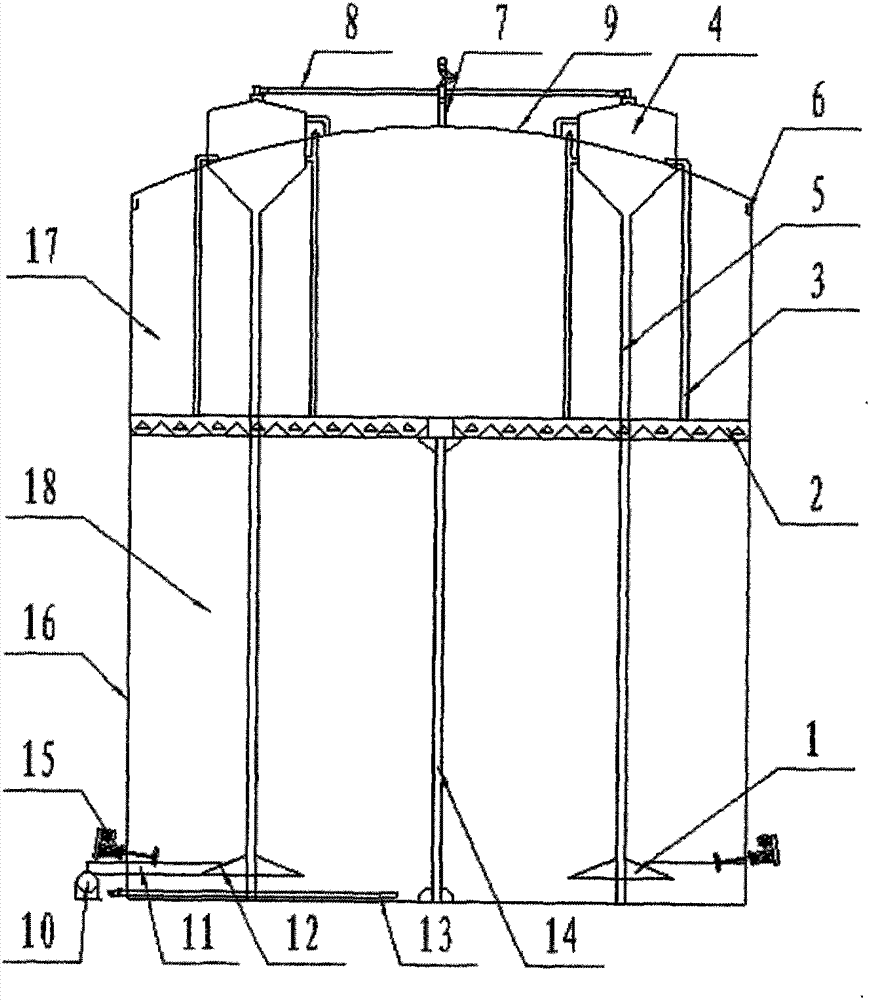

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

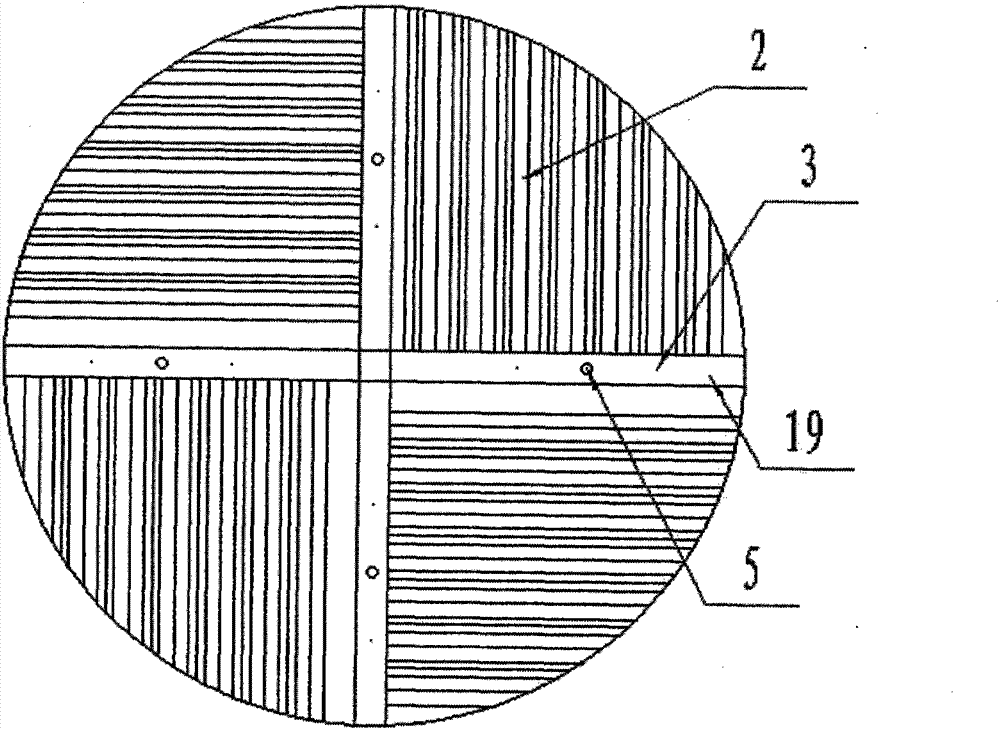

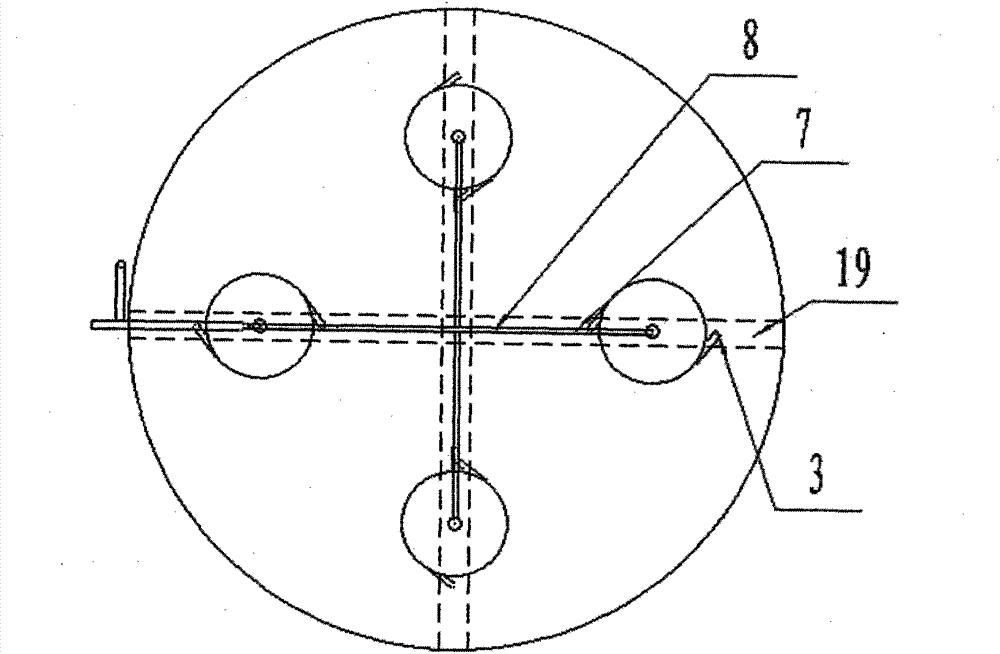

[0024] A self-circulating anaerobic reactor, comprising a tank body 16 which is provided with a gas collector 2 through a central support column 14 inside, and the gas collector 2 divides the tank body 16 into an upper reaction chamber 17 and a lower reaction chamber 18. The top of the tank body 16 is equipped with an arched air collecting hood 9, and the bottom is provided with a feed distributor 10, a water inlet pipe 11, a mud discharge pipe 13 and a side-entry agitator 15; A group of self-circulation systems, each group of self-circulation systems includes a return pipe 5, a biogas pipe 7 and a stripping pipe 3, the upper end of the return pipe 5 is connected to the gas-liquid separator 4 located in the upper rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com