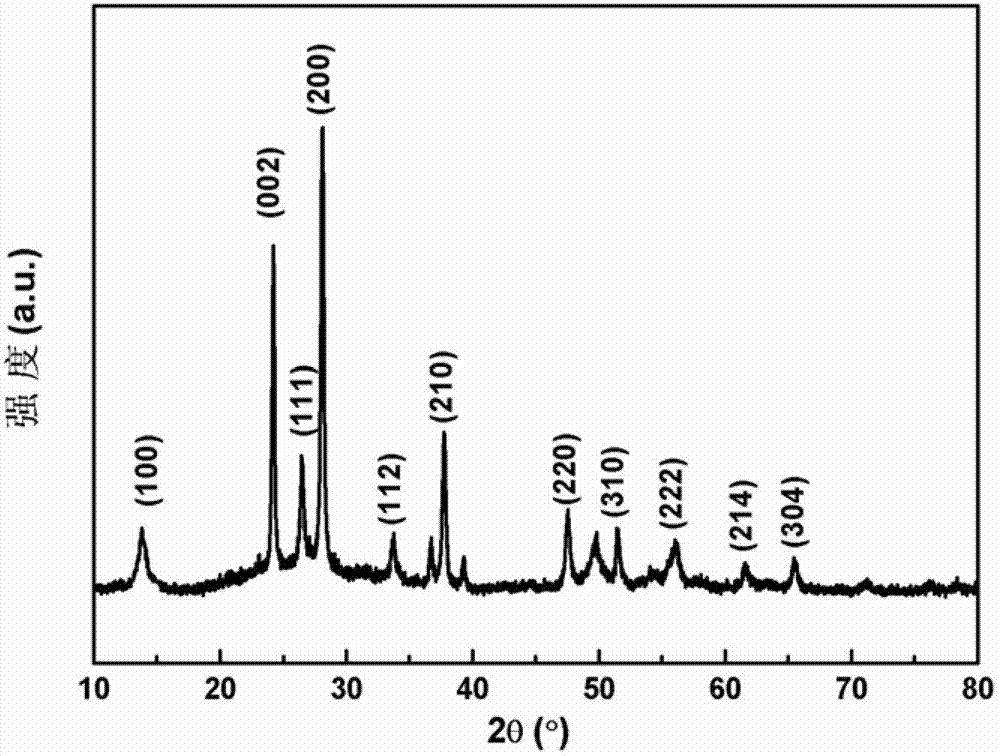

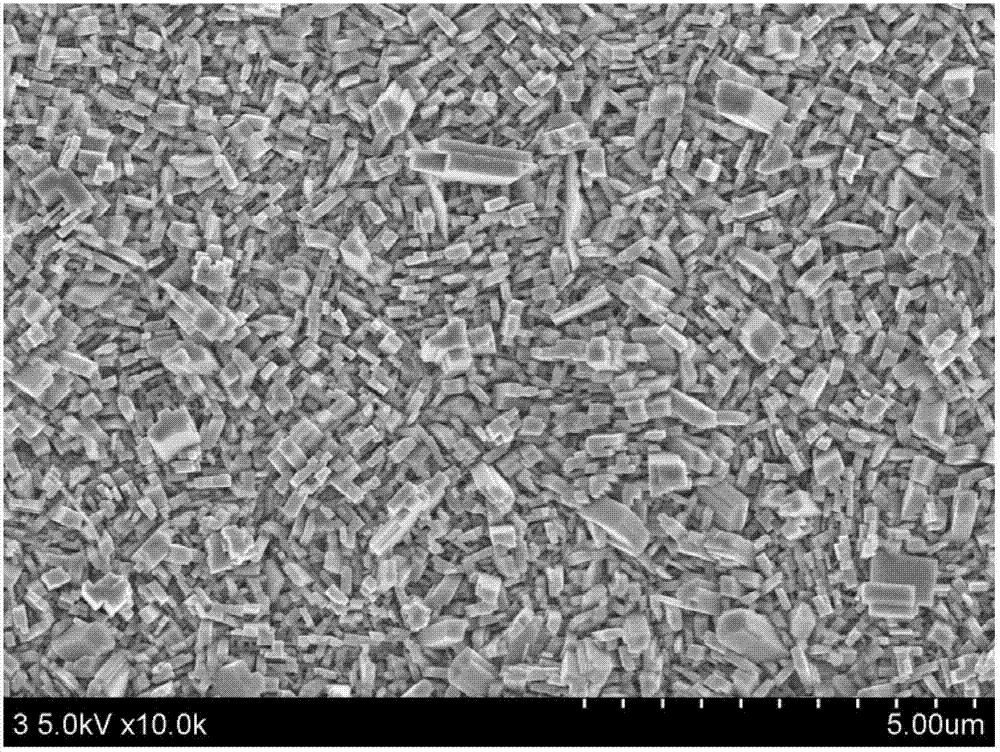

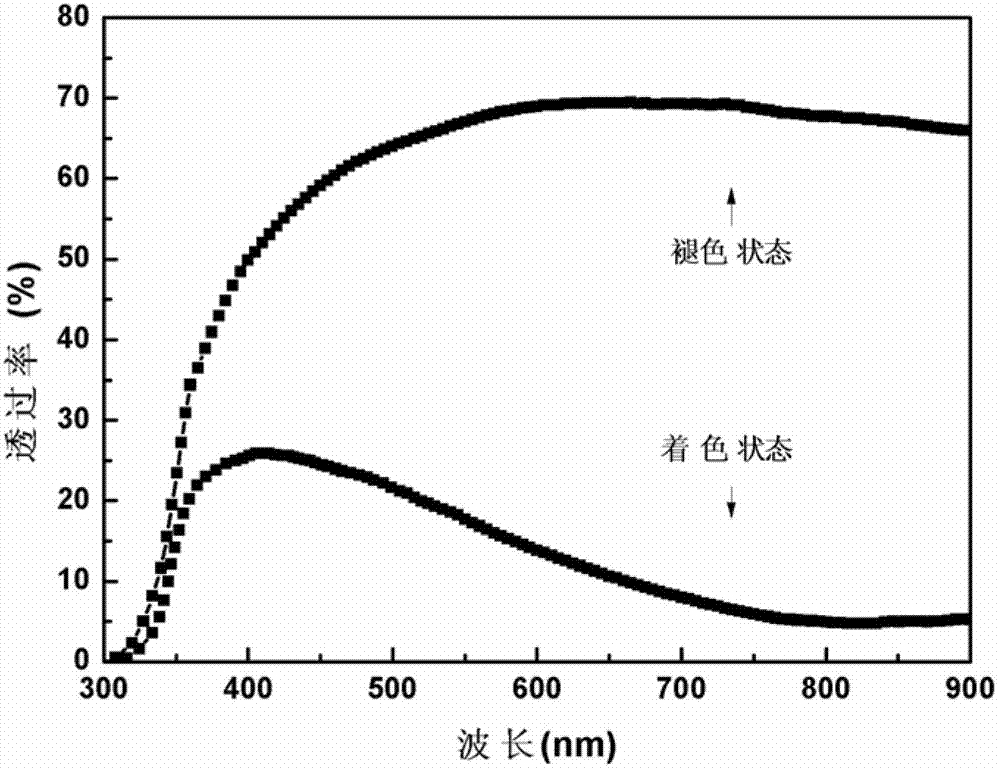

Method for preparing vertically aligned tungsten oxide nano structural electrochromic film

A nanostructure and electrochromic technology is applied in the field of preparation of tungsten oxide nanostructure electrochromic thin films, which can solve the problems of affecting coloring efficiency, unable to use fast-response devices, and low cycle times, and achieves improved electrochemical stability, Beneficial to electron conduction and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The FTO conductive glass was sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 20 minutes, and dried for later use. Weigh 5g of tungstic acid and dissolve it in a mixed solution of 60mL of hydrogen peroxide and 140mL of water, heat to 95°C, cool down after the tungstic acid is completely dissolved to obtain a transparent sol; then spin-coat the transparent sol on the surface of FTO conductive glass cleaned by ultrasonic , and calcined at 500° C. for 0.5 hour to obtain a tungsten oxide seed layer. Prepare a reaction solution containing 10.5mL of transparent sol, 3.5mL of hydrochloric acid (3mol / L), 1.2mmol of urea, and 42mL of water, and then immerse the FTO conductive glass with the tungsten oxide seed layer obtained above into a hydrothermal solution containing the reaction solution. In the kettle, keep warm at 180°C for 12 hours, and finally cool down to room temperature naturally, take out the FTO conductive glass, wash it with...

Embodiment 2

[0036]The FTO conductive glass was sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 20 minutes, and dried for later use. Weigh 2.5g of tungstic acid and dissolve it in a mixed solution of 60mL of hydrogen peroxide and 140mL of water, heat to 80°C, cool down after the tungstic acid is completely dissolved to obtain a transparent sol; then spin-coat the transparent sol on the ultrasonically cleaned FTO conductive glass The surface was calcined at 350°C for 2 hours to obtain a tungsten oxide seed layer. Prepare a reaction solution containing 10.5mL of transparent sol, 3.5mL of hydrochloric acid (3mol / L), 3.6mmol of urea, and 42mL of water, and then immerse the FTO conductive glass with the tungsten oxide seed layer obtained above into a hydrothermal solution containing the reaction solution. In the kettle, keep warm at 180°C for 12 hours, and finally cool down to room temperature naturally, take out the FTO conductive glass, wash it with w...

Embodiment 3

[0038] The FTO conductive glass was sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 30 minutes, and dried for later use. Weigh 5g of tungstic acid and dissolve it in a mixed solution of 60mL of hydrogen peroxide and 140mL of water, heat to 95°C, cool down after the tungstic acid is completely dissolved to obtain a transparent sol; then spin-coat the transparent sol on the surface of FTO conductive glass cleaned by ultrasonic , and calcined at 400° C. for 0.5 hour to obtain a tungsten oxide seed layer. Prepare a reaction solution containing 10.5mL transparent sol, 3.5mL hydrochloric acid (6mol / L), 1.2mmol urea, 21mL water, and 21mL acetonitrile, and then immerse the FTO conductive glass with the tungsten oxide seed layer obtained above into the reaction solution In a hydrothermal kettle, keep warm at 180°C for 6 hours, and finally cool down to room temperature naturally, take out the FTO conductive glass, wash it with water and ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com