Method for purifying lactoferrin from milk serum by using an expanded bed adsorption technology

A lactoferrin, expanding bed technology, applied to transferrin, animal/human proteins, specific peptides, etc., can solve the problems of cumbersome operation, long time, poor adsorption selectivity of lactoferrin, etc., and achieve simplified process and simple steps. The effect of easy operation and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Add water to dissolve sweet whey powder to make 1 L of whey solution with a mass percent concentration of 50 g / L, and adjust the pH to 7.0 with NaOH;

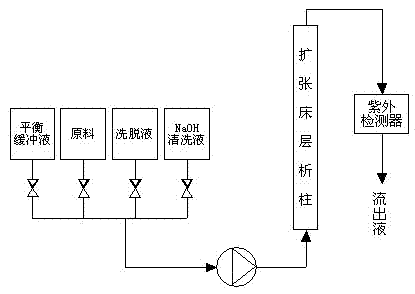

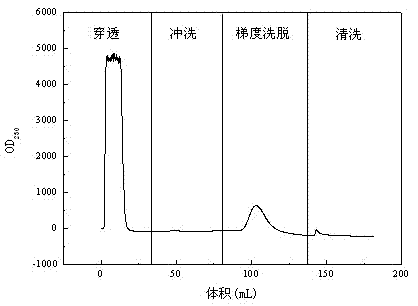

[0036] 2) The expanded bed is filled with cation exchange chromatography medium, the cation exchange medium is Fastline SP; the phosphate buffer with pH 7.0 is passed through the bed from bottom to top, and the expanded bed is balanced. When the bed expands stably, the expansion rate is 2.0;

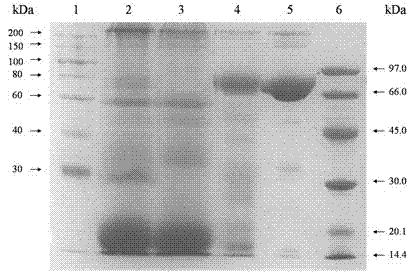

[0037] 3) Pass through the solution in step 1) for adsorption, then pass through the buffer used in step 2) to wash until no protein is washed out, then elute with pH 7.0 phosphate buffer containing 0.5 M NaCl, collect the eluted Liquid, its purity is 90%, and the recovery rate of lactoferrin is 83%;

[0038] 4) Wash the medium in place with 0.2 M NaOH and finally re-equilibrate the medium with pH 7.0 phosphate buffer.

[0039] In step 3), when feeding the solution in step 1) for adsorption, keep the operating flow rate the sam...

Embodiment 2

[0042] 1) Add water to dissolve sweet whey powder to make 1 L of whey solution with a mass percentage concentration of 20g / L, and adjust the pH to 8.0 with NaOH;

[0043] 2) Fill the expanded bed with cation exchange chromatography medium, the cation exchange medium is Fastline SP; use pH 8.0 phosphate buffer to pass through the bed from bottom to top, balance the expanded bed, and when the bed expands stably, the expansion rate is 2.6;

[0044] 3) Pass through the solution in step 1) for adsorption, then pass through the buffer used in step 2) to wash until no protein is washed out, then elute with phosphate buffer solution containing 1 M NaCl at pH 8.0, and collect the eluted Liquid, its purity is 93%, and lactoferrin recovery rate is 47%;

[0045] 4) Wash the medium in place with 0.2 M NaOH and finally re-equilibrate the medium with pH 7.0 phosphate buffer.

[0046] In step 3), when feeding the solution in step 1) for adsorption, keep the operating flow rate the same as the ...

Embodiment 3

[0048] 1) Add water to dissolve sweet whey powder to make 1 L of whey solution with a mass percentage concentration of 80g / L, and adjust the pH to 7.5 with NaOH;

[0049] 2) Fill the expanded bed with cation exchange chromatography medium, the cation exchange medium is Streamline SP; use pH 7.5 phosphate buffer to pass through the bed from bottom to top, balance the expanded bed, and when the bed expands stably, the expansion ratio is 1.8;

[0050] 3) Pass through the solution in step 1) for adsorption, then pass through the buffer used in step 2) to wash until no protein is washed out, then elute with pH 10.0 carbonate buffer containing 0.5 M NaCl, collect the washed Deliquification, its purity is 88%, and the recovery rate of lactoferrin is 86%;

[0051] 4) Wash the medium in place with 0.2 M NaOH and finally re-equilibrate the medium with pH 7.0 phosphate buffer.

[0052] In step 3), when feeding the solution in step 1) for adsorption, keep the operating flow rate the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com