Polyethylene glycol hydrogel for orthotopic injection and preparation method thereof

A polyethylene glycol type, in situ injection technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as expensive, difficult to industrialize, and harsh conditions for star-shaped polyethylene glycol synthesis, and achieve Effects of reduced reaction energy consumption, simple operation, good biocompatibility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-26

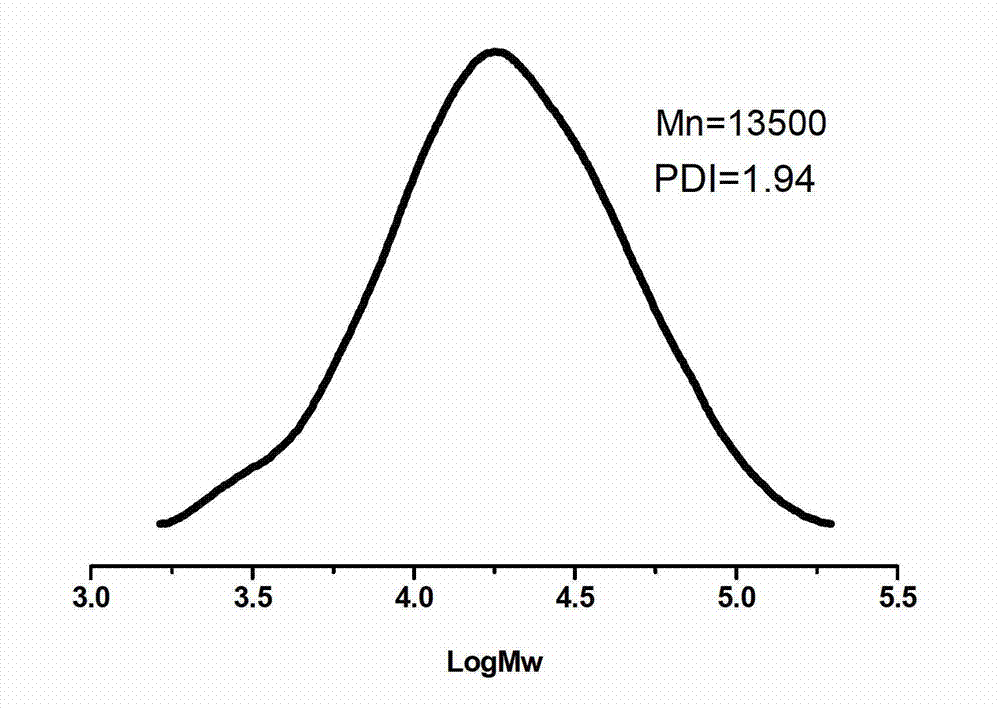

[0039] Embodiment 1-26, different rare earth triflate Ln(OTf) 3 Catalyze the synthesis of polymercapto or polyether esters with multiple double bonds (the number average molecular weight of polyethylene glycol used is 1000g / mol).

Embodiment 1

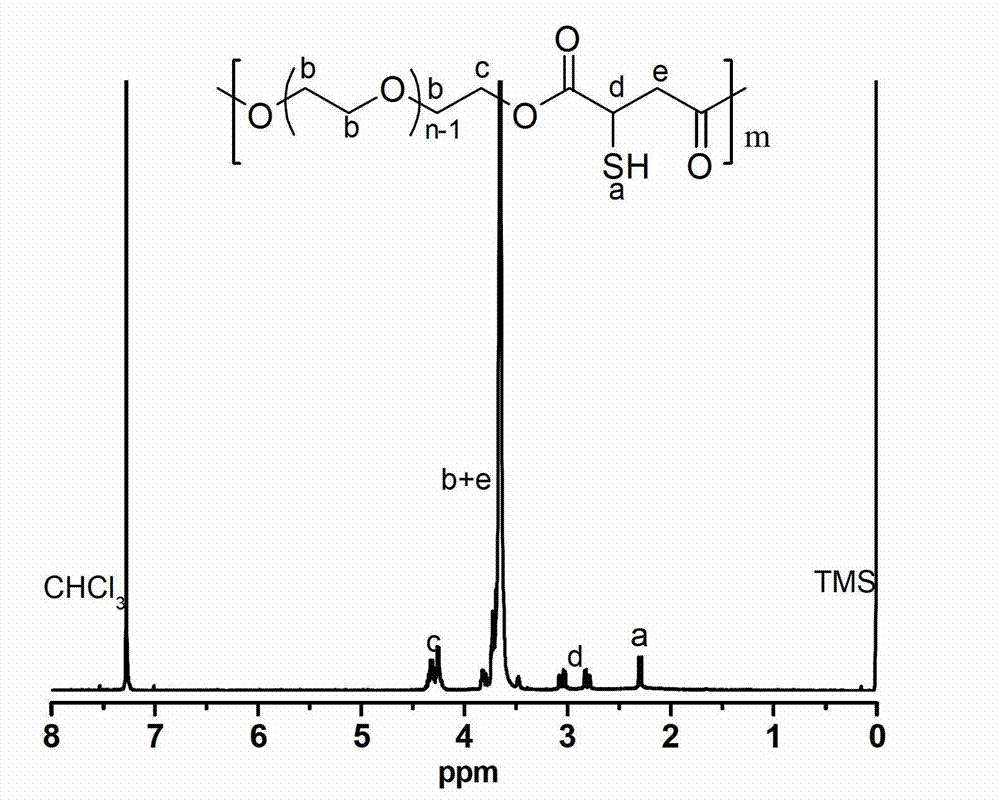

[0040] Embodiment 1, scandium trifluoromethanesulfonate Sc (OTf) 3 Synthesis of Catalyzed Polymercapto Polyether Ester

[0041] Add 45g (0.045mol) of polyethylene glycol 1000 to a 250mL three-neck flask, add 100mL of anhydrous toluene to azeotropically remove water at 140°C; then add 6.62g (0.045mol) of thiomalic acid, 0.33g (0.67 mmol) scandium trifluoromethanesulfonate catalyst. Under the action of mechanical stirring, react at 80°C for 3 hours in a nitrogen atmosphere, then connect the circulating water pump to depressurize the reaction for 4 hours, keep the temperature at 80°C, and the pressure of the decompression reaction is 3mmHg, after slowly raising the temperature to 100°C, change the rotary vane type The vacuum oil pump continued the decompression reaction at 100° C. for 8 hours, and the reaction pressure was 0.3 mmHg. After the polycondensation reaction, the obtained polymer was dissolved in dichloromethane, extracted twice with saturated brine to remove the cata...

Embodiment 2

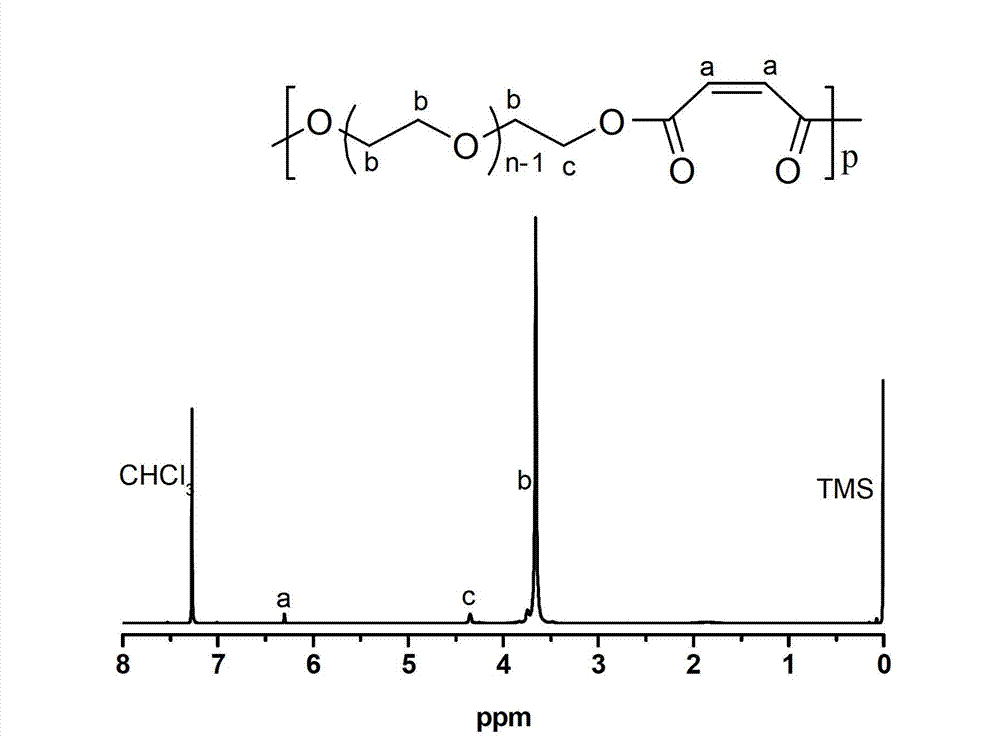

[0045] Embodiment 2, scandium trifluoromethanesulfonate Sc (OTf) 3 Catalyzed synthesis of polyether esters with multiple double bonds

[0046] Add 45g (0.045mol) polyethylene glycol 1000 to a 250mL three-necked flask, add 100mL anhydrous toluene to remove water azeotropically at 140°C; then add 4.34g (0.045mol) maleic anhydride, 0.33g (0.67mmol) ) scandium triflate catalyst. Under the action of mechanical stirring, after reacting at 100°C for 3 hours in a nitrogen atmosphere, connect the circulating water pump and maintain it at 100°C for 4 hours under reduced pressure. The oil pump continued the decompression reaction at 120° C. for 8 hours, and the reaction pressure was 0.3 mmHg. After the polycondensation reaction, the obtained polymer was dissolved in tetrahydrofuran, and the catalyst was removed through a separation column filled with neutral alumina, the solution was retained, concentrated by rotary evaporation, and finally a large amount of cold ether was added under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com