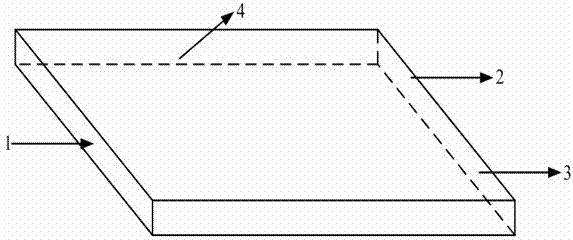

Pore-shaped flat plate TeraHertz wave polarization beam splitter with quadrilateral structure

A polarization beam splitter and quadrilateral technology, applied in the direction of instruments, optical waveguide coupling, light guide, etc., can solve the problems of large size, limited coverage, complex structure, etc., and achieve low cost, simple structure, and high beam splitting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

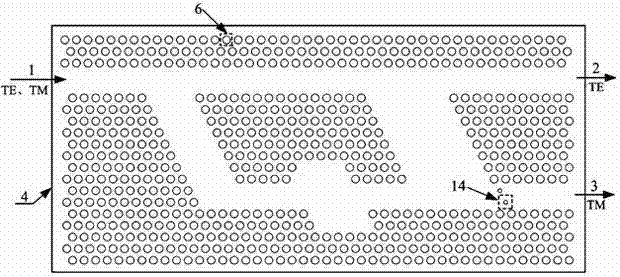

[0017] The hole-shaped hollow plate polarizer has a length of 2600 μm and a width of 1300 μm, and the material is gallium arsenide with a refractive index of 3.25. The hole radius of the large hole-shaped hollow is 20 μm, and the distance between adjacent holes is 60 μm. The space between the hollows is 60 μm. The upper void is formed by removing the large hole-like cutouts of the fourth and fifth rows. The left parallelogram void, the right parallelogram void, and the lower parallelogram void are respectively formed by removing 8×4, 8×7, and 2×5 large hole-shaped hollows, and the left parallelogram void is parallel to the right The large hole-like cutouts for quadrilateral void removal are in the same row. The left side of the lower lateral gap is parallel to the left side of the left parallelogram gap, and the right side is parallel to the right side of the right parallelogram gap. between. The isosceles trapezoidal void on the lower side is formed by removing two rows o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com