Method for controlling pH value of process water circulation system for ethylene production by steam cracking

A cracking technology for producing ethylene and a control method, which is applied in the field of controlling the pH of the water circulation system of the steam cracking process for producing ethylene, and can solve problems affecting the normal and stable production of the device, corrosion of the dilution steam generator, emulsification of quenching water, etc., to ensure long-term stable production , highlight the substantive features, the effect of water quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

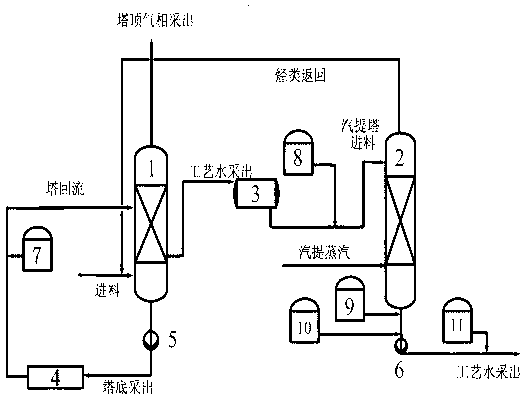

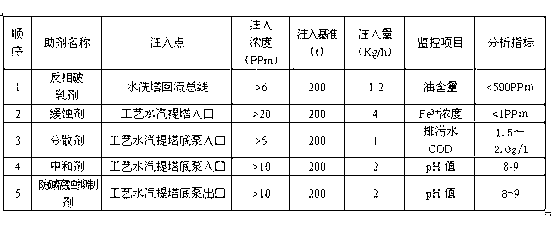

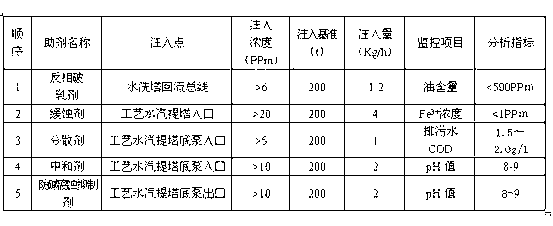

[0013] A method for controlling the acidity and alkalinity of the water circulation system of the steam cracking ethylene production process, which is characterized in that: the aqueous solution containing the concentration of 10wt% cycloheptide cationic polyether with a pH value of 4.7, and the aqueous solution containing a concentration of 10 to 30wt% dihydrocyclopropane with a pH value > 6.9 Pentylene glycol solution of ethylenetriaminepentamethylenephosphonic acid, alcohol ether solution containing 10wt% naphthalene at pH value 60wt% at pH value > 13, pH The sodium hydroxide aqueous solution with a concentration>10wt% of the value>13 is an inverse demulsifier, a corrosion inhibitor, a dispersant, a neutralizer, and an anti-alkali corrosion inhibitor. The injection sequence, injection point and injection volume given in Table 1 will be injected sequentially, and adjusted according to the monitoring items and analysis indicators:

[0014] Table 1. Auxiliary injection point,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com