Potassium-sodium niobate-based leadless piezoelectric ceramic and two-step sintering preparation method thereof

A potassium-sodium niobate-based, lead-free piezoelectric technology, which is applied in the field of ceramic compositions, can solve the problems of alkali metal loss and achieve the effect of shortening the time and making up for the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Ingredients synthesis

[0025] Press (Na 0.52 K 0.44 Li 0.04 )(Nb 0.88 Sb 0.08 Ta 0.04 )O 3 Weigh the raw materials sodium carbonate, potassium carbonate, lithium carbonate, niobium pentoxide, tantalum pentoxide and antimony trioxide, mix them, put them into a ball mill jar, and the ball mill medium is absolute ethanol and zirconia balls , ball milled for 6 hours, and the ball milling speed was 800 rpm; the slurry was dried in an oven at 80°C to obtain the original ingredients of A; the same conditions were obtained by KNbO 3 The stoichiometric ratio of raw materials is weighed, mixed, ball milled and dried to obtain the raw ingredients of B;

[0026] (2) pre-burning

[0027] Put the raw ingredients of A and B obtained in step (1) into the crucible respectively, cover and seal, keep warm in a muffle furnace at 800°C for 3 hours, cool naturally to room temperature, and take out the furnace to obtain A and B powders;

[0028] (3) Secondary ball milling

[00...

Embodiment 2

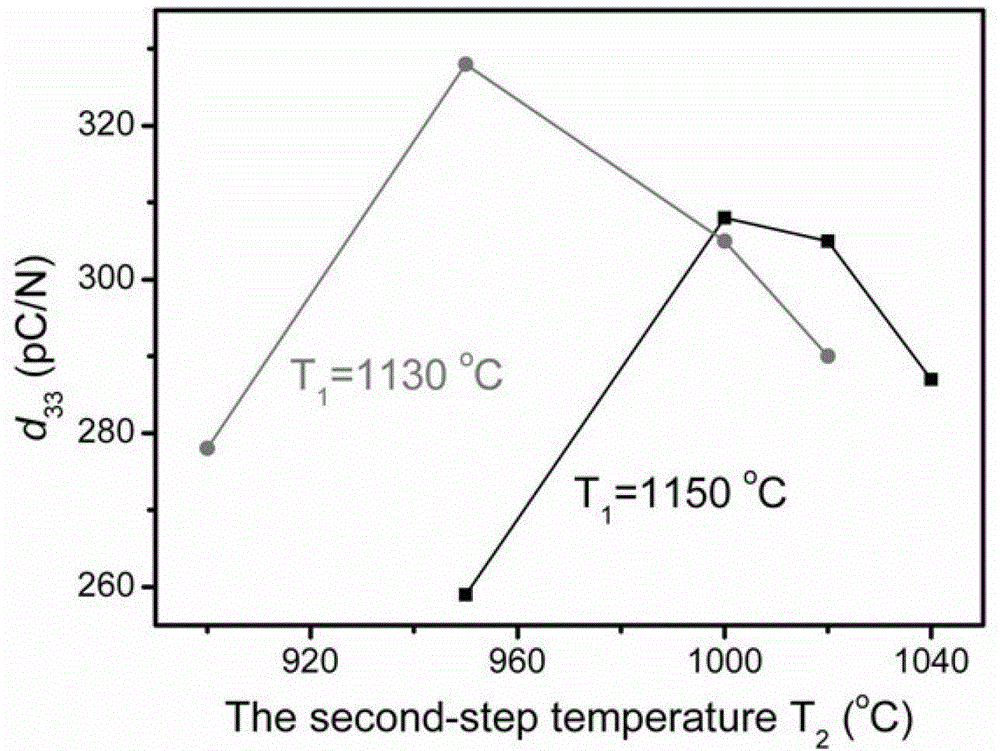

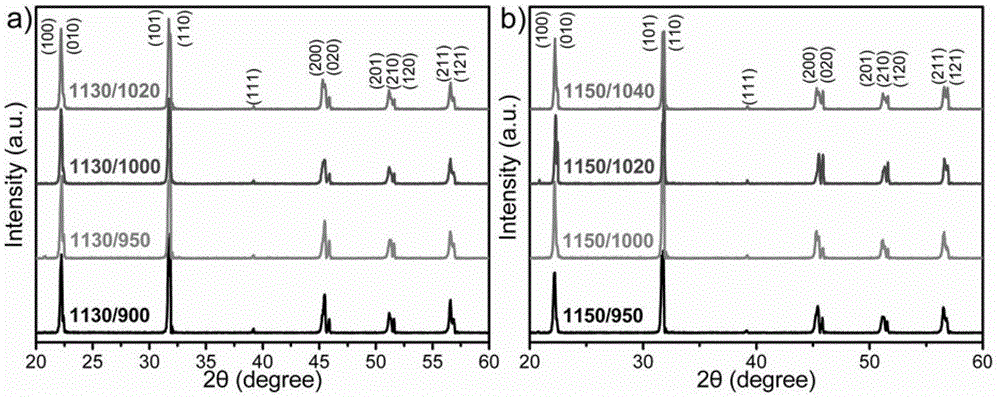

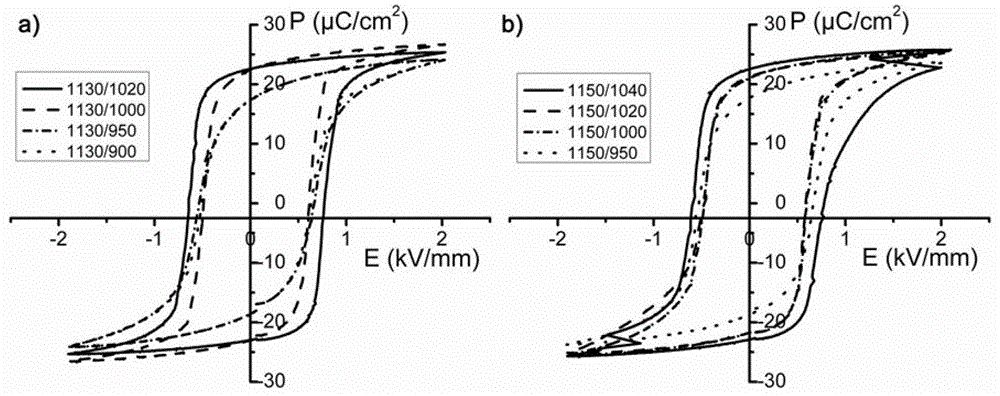

[0039] Using the same method as in Example 1, the sintering temperature in the first step is 1130° C., and the sintering temperature in the second step is 1020° C. to prepare potassium sodium niobate-based piezoelectric ceramics.

Embodiment 3

[0041] Using the same method as in Example 1, the sintering temperature in the first step is 1130° C., and the sintering temperature in the second step is 1000° C. to prepare potassium sodium niobate-based piezoelectric ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com