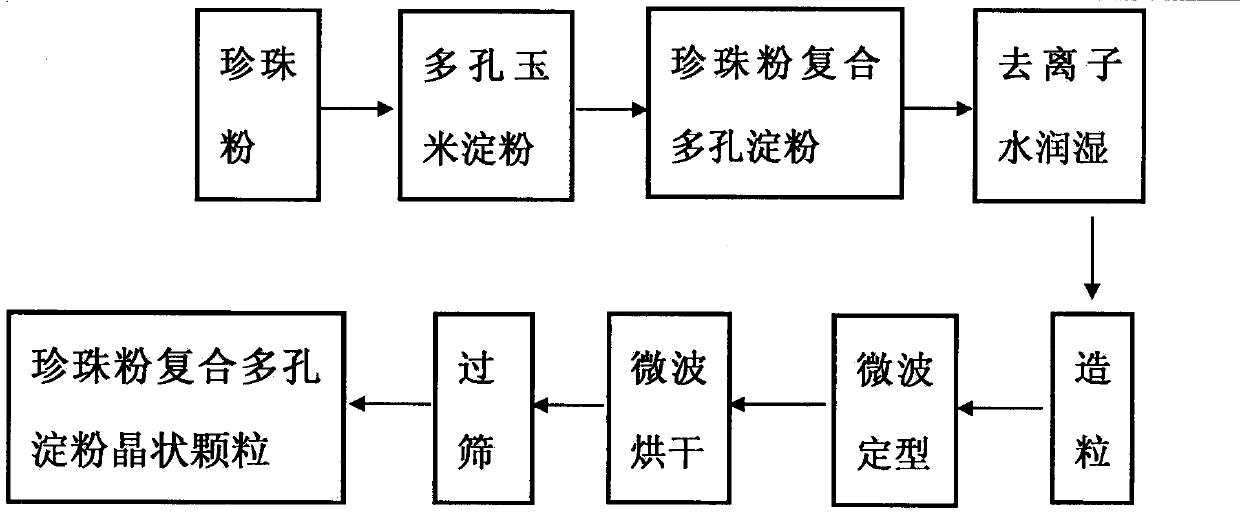

Preparation method of pearl powder composite porous starch crystalline particles and application in cigarette filter tip

A technology of porous starch and cigarette filter, which is applied in applications, e-liquid filter elements, tobacco, etc. It can solve the problems of potential safety hazards in chemical adhesives, low yield of porous starch particles, and restrictions on the application of cigarettes, so as to improve cigarette smoking. Inhalation quality, reduced smoke irritation, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Get 50g pearl powder, join in 1Kg porous cornstarch, and mix well. Measure 800mL of deionized water and spray evenly into the mixed powder of pearl powder and porous starch to make the powder wet. The wetted pearl powder composite porous starch is passed through a 20-mesh sieve by extrusion granulation to obtain granules smaller than 20 mesh. Put the above granules into the microwave oven, under the condition of no dehumidification, the 2 The microwave power density of the particles was intermittently treated for a total of 3 minutes for gelation and setting; 2 The microwave power density intermittently treats the granules for a total of 6 minutes to dry the pearl powder composite porous starch granules. The above microwave treatment should control the temperature not to exceed 100°C. The obtained granules are respectively passed through 20-mesh and 40-mesh standard sieves to obtain 20-40 mesh pearl powder composite porous starch crystalline particles.

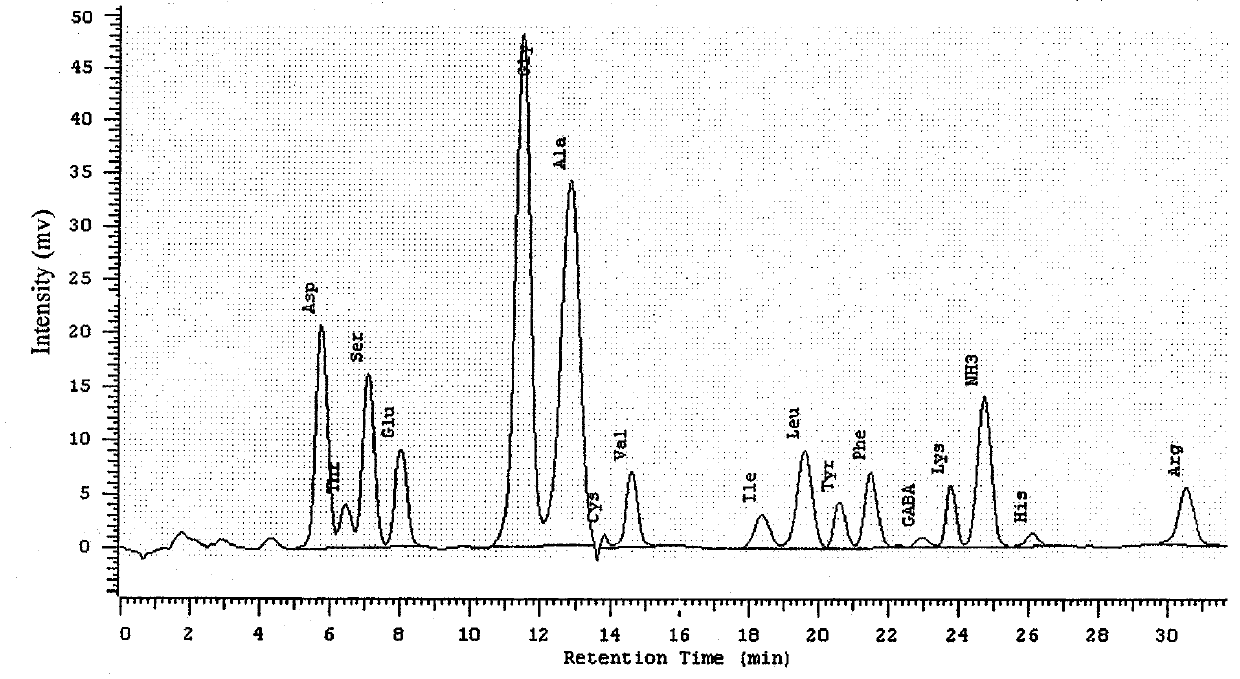

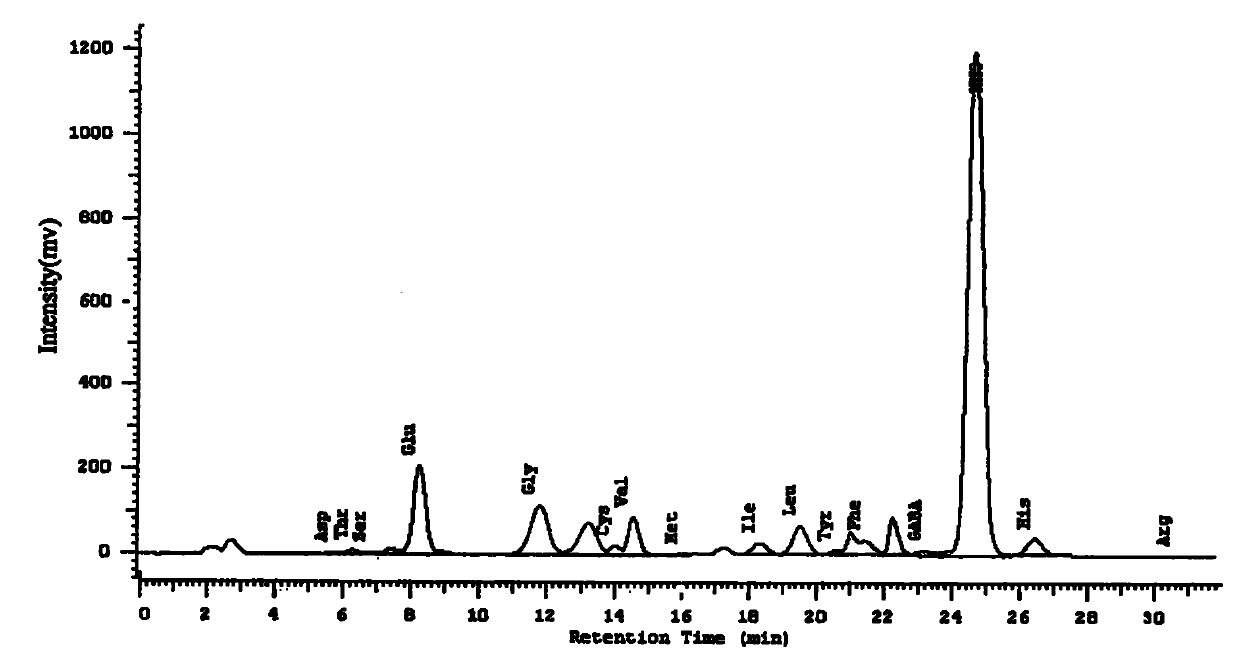

[0039] The d...

Embodiment 2

[0045] Take by weighing 30g pearl powder, join in 1Kg porous cornstarch, and mix well. Measure 900mL of deionized powder and evenly spray it into the mixed powder of pearl powder and porous starch to make the powder wet. The wetted pearl powder composite porous starch is passed through a 20-mesh sieve by extrusion granulation to obtain granules smaller than 20 mesh. Put the above granules into the microwave oven, under the condition of no dehumidification, the 2 The microwave power density of the particles was intermittently treated for a total of 4 minutes for gelation and setting; 2 The microwave power density intermittently treats the granules for a total of 7 minutes to dry the pearl powder composite porous starch granules. The above microwave treatment should control the temperature not to exceed 100°C. The obtained granules are respectively passed through 20-mesh and 40-mesh standard sieves to obtain 20-40 mesh pearl powder composite porous starch crystalline particles...

Embodiment 3

[0047] Get 10g pearl powder, join in 1Kg porous cornstarch, and mix well. Measure 1000mL of deionized water and spray evenly into the mixed powder of pearl powder and porous starch to make the powder wet. The wetted pearl powder and porous starch are passed through a 20-mesh sieve by extrusion granulation to obtain granules smaller than 20 mesh. Put the above granules into the microwave oven, under the condition of no dehumidification, the 2 The microwave power density of the particle is intermittently treated for a total of 5 minutes for gelation and setting; 2 The microwave power density intermittently treats the granules for a total of 8 minutes to dry the pearl powder composite porous starch granules. The above microwave treatment should control the temperature not to exceed 100°C. The obtained granules are respectively passed through 20-mesh and 40-mesh standard sieves to obtain 20-40 mesh pearl powder composite porous starch crystalline particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com