Pressure-sensitive adhesive compositions, pressure-sensitive adhesive layers, and pressure-sensitive adhesive sheets

A composition, adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0323]

[0324] 200 parts by weight of 2-ethylhexyl acrylate, 8 parts by weight of 2-hydroxyethyl acrylate, and 2,2' - 0.4 parts by weight of azobisisobutyronitrile, 312 parts by weight of ethyl acetate, introduce nitrogen gas while stirring slowly, keep the liquid temperature in the flask at around 65°C, and carry out polymerization reaction for 6 hours to prepare acrylic acid Polymer (A) solution (40% by weight).

[0325] The weight average molecular weight of the said acrylic polymer (A) was 540,000, glass transition temperature (Tg) was -68 degreeC, and the acid value was 0.0.

[0326]

[0327] 120 parts by weight of toluene and 10 parts by weight of 2,2'-azobisisobutyronitrile were added to a four-necked flask equipped with a stirring blade, a thermometer, a nitrogen gas introduction pipe, and a cooler, and nitrogen gas was introduced while slowly stirring. The liquid temperature was brought to 75°C, and while maintaining the liquid temperature at 75°C, 50 parts by w...

Embodiment I-1

[0336] [Preparation of binder solution]

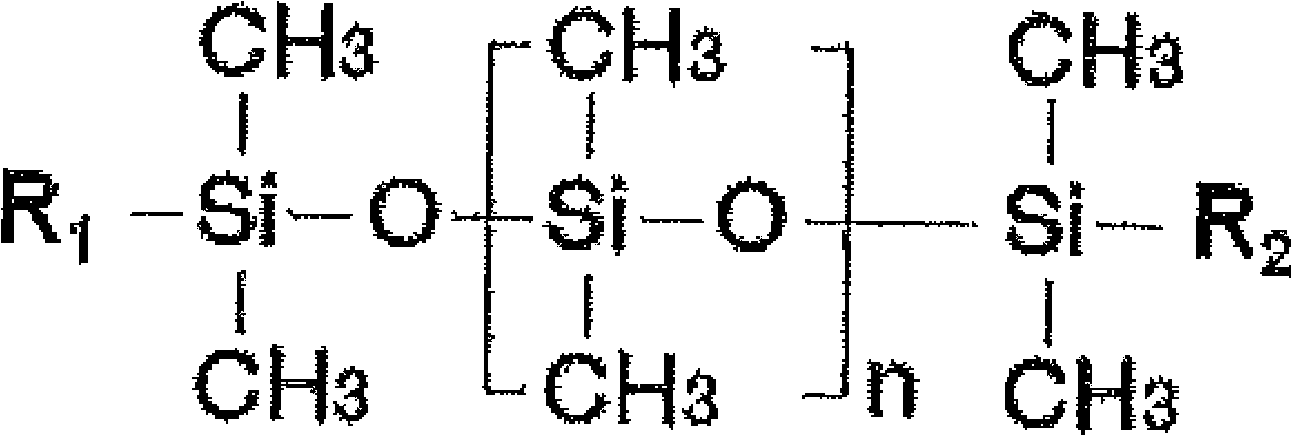

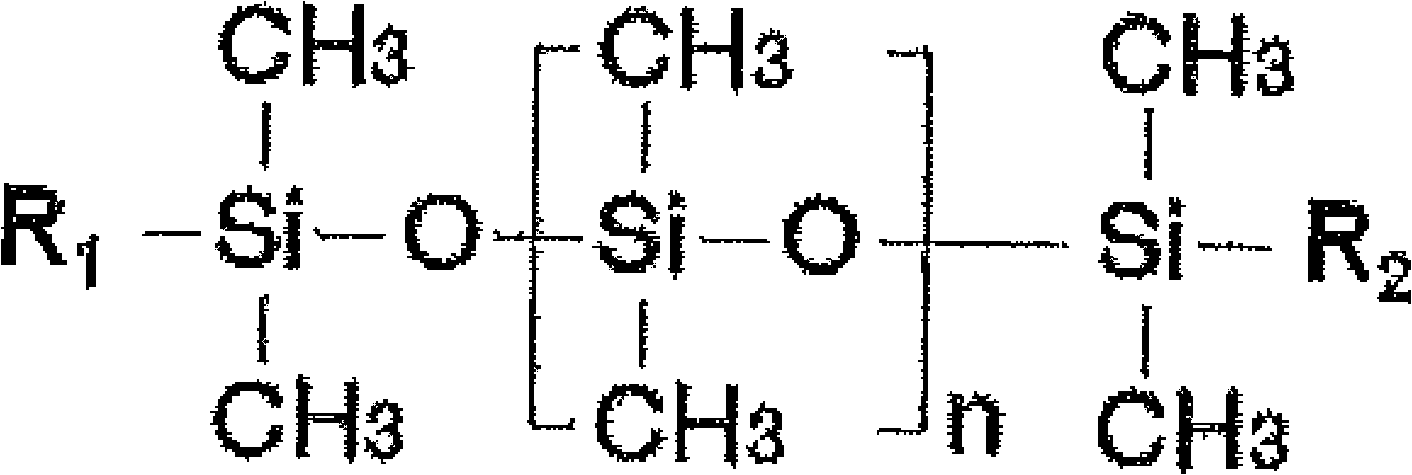

[0337] Dilute the above-mentioned acrylic polymer (A) solution (40% by weight) to 20% by weight with ethyl acetate, and add to 100 parts by weight of the solution: The main chain type A of the polyorganosiloxane (SF8427 manufactured by Toray Dow Corning Co., Ltd.: polyoxyalkylene chain terminal hydroxyl group) was diluted to 0.6 parts by weight of a 10% solution, and trimethylolpropane / toluene di 0.8 parts by weight of isocyanate (manufactured by Nippon Polyurethane Industry Co., Ltd., Coronate L, 75% by weight) and 0.4 parts by weight of dibutyltin dilaurate (1% by weight of ethyl acetate solution) as a crosslinking catalyst were mixed and stirred to prepare an acrylic adhesive. Mixture solution (1).

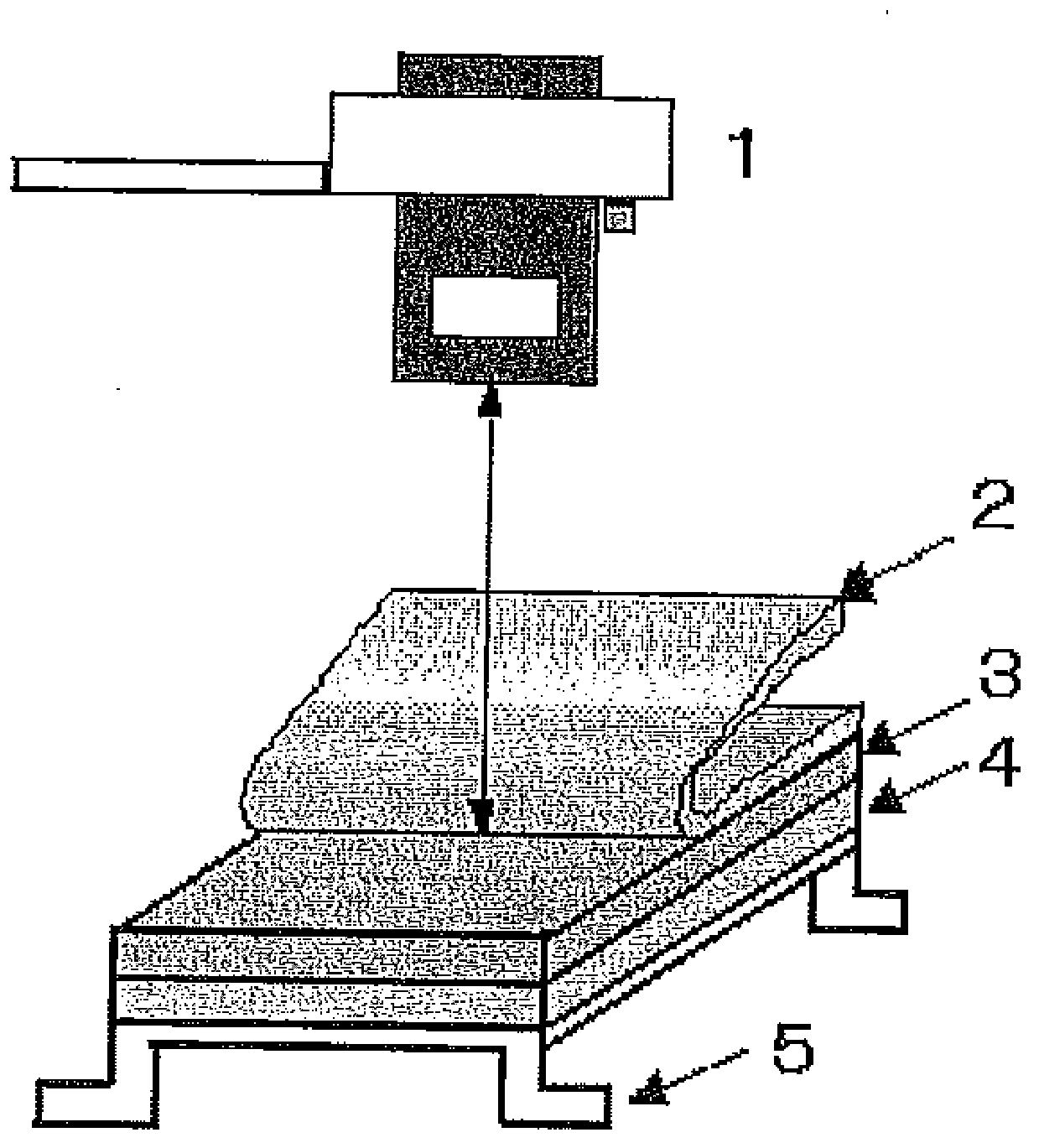

[0338] 〔Production of adhesive sheet〕

[0339] The above-mentioned acrylic adhesive solution (1) was applied to the surface of the antistatic-treated film opposite to the antistatic-treated surface, and heated at 130° C. for 2 minutes...

Embodiment I-2

[0342] [Preparation of binder solution]

[0343] Main chain type B (X-22-4272 Shin-Etsu Chemical Co., Ltd.: polyoxyalkylene chain terminal hydroxyl group) was used instead of main chain type A as a polyorganosiloxane having a polyoxyalkylene chain in the main chain, Except for this, the same operation as in Example I-1 was carried out to prepare an acrylic adhesive solution (2).

[0344] 〔Production of adhesive sheet〕

[0345] Except having used the acrylic adhesive solution (2), it carried out similarly to Example I-1, and produced the adhesive sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com