Method for preparing bio-oil through supercritical pyrolysis of civil sludge

A municipal sludge and supercritical technology, applied in pyrolysis treatment sludge, preparation of liquid hydrocarbon mixture, petroleum industry, etc., can solve the problems of high disposal cost and complicated pretreatment, achieve high added value and avoid secondary Effects of pollution problems, good environment and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

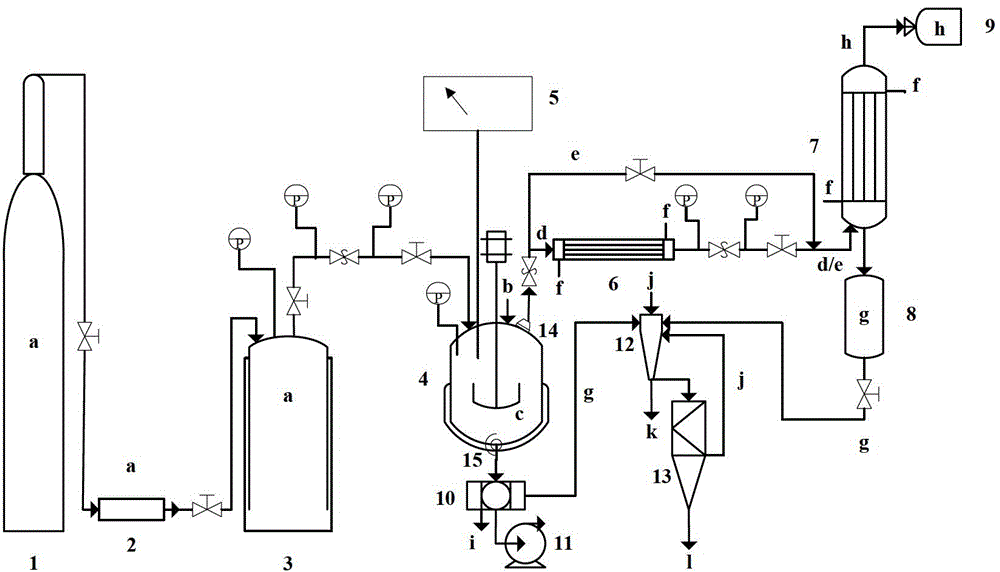

[0041] figure 1 It is a schematic structural diagram of the processing system of the method for preparing bio-oil by applying municipal sludge supercritical pyrolysis of the present invention. The reaction kettle of the processing system is a high-pressure reaction kettle 4, which is a sequence batch type high-pressure-resistant sealed reaction kettle; the front end of the high-pressure reaction kettle 4 is sequentially provided with a nitrogen storage tank 1, a booster pump 2 and a high-pressure gas storage tank 3. The high-pressure reaction kettle 4 is connected, and a valve and a pressure gauge are arranged on the connecting pipeline; The ends are respectively provided with a liquid collecting tank 8 and a gas collecting bag 9; the high pressure reaction kettle (4) is also provided with a kettle body rotating outlet 15, and the kettle body rotating outlet 15 is connected with the filter 10, the liquid separator 12 and the rotating outlet in turn. The evaporator 13 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com