Patterned multilayer array paper chip, preparation method and application thereof

A multi-layer array, paper chip technology, applied in chemical instruments and methods, analysis by chemical reaction of materials, containers for laboratory use, etc. The effect of fast kinetic process, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

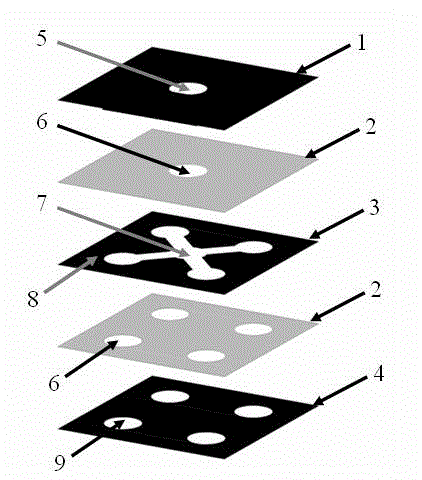

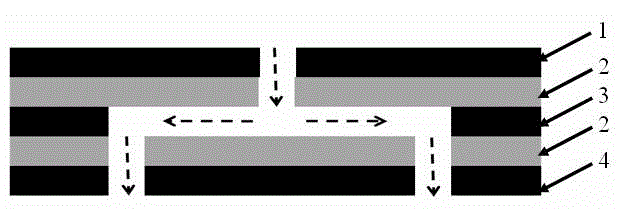

[0019] Put Whatman? No. 1 filter paper into the wax jet printer, and print the designed pattern on the filter paper (such as image 3 shown), and press the image 3 Cut out the outer contour; bake the cut filter paper in an oven at 140°C for 3 minutes; take out the baked filter paper and place it in a dark place until its temperature drops to room temperature. Put 3M-300lse double-sided tape, press image 3 The pattern shown is punched and contoured. Peel off the protective film on one side of the double-sided tape, stick it to the first filter paper layer, then peel off the other protective film, and stick it to the second filter paper layer. Repeat the above steps until the assembly of the entire patterned multilayer array paper chip is completed. The schematic diagram of the structure of the multilayer array paper chip prepared according to the above steps is as follows: image 3 shown. Through this chip, a single sample can be divided into 16 parallel samples in paral...

Embodiment 2

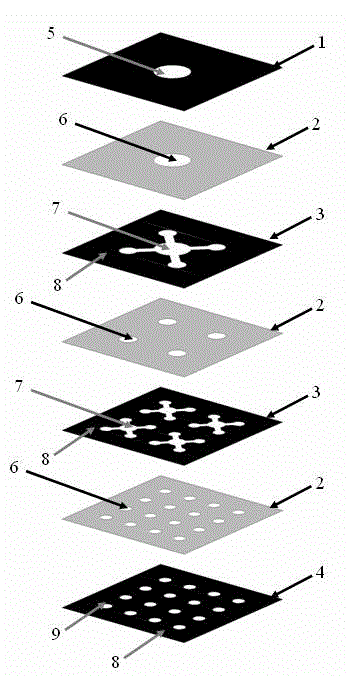

[0021] Put Whatman? No. 1 filter paper into the wax jet printer, and print the designed pattern on the filter paper (such as Figure 4 shown), and press the Figure 4 Cut out the outer contour; bake the cut filter paper in an oven at 140°C for 3 minutes; take out the baked filter paper and place it in a dark place until its temperature drops to room temperature. Put 3M-300lse double-sided tape, press Figure 4 The pattern shown is punched and contoured. Peel off the protective film on one side of the double-sided tape, stick it to the first filter paper layer, then peel off the other protective film, and stick it to the second filter paper layer. Repeat the above steps until the assembly of the entire patterned multilayer array paper chip is completed. The schematic diagram of the structure of the multilayer array paper chip prepared according to the above steps is as follows: Figure 4 shown. Through this chip, the 4 samples to be tested can be divided into 4 parallel sa...

Embodiment 3

[0023] Put Whatman? No. 1 filter paper into the wax jet printer, and print the designed pattern on the filter paper (such as Figure 5 shown), and press the Figure 5 Cut out the outer contour; bake the cut filter paper in an oven at 140°C for 3 minutes; take out the baked filter paper and place it in a dark place until its temperature drops to room temperature. Put 3M-300lse double-sided tape, press Figure 5 The pattern shown is punched and contoured. Peel off the protective film on one side of the double-sided tape, stick it to the first filter paper layer, then peel off the other protective film, and stick it to the second filter paper layer. Repeat the above steps until the assembly of the entire patterned multilayer array paper chip is completed. The schematic diagram of the structure of the multilayer array paper chip prepared according to the above steps is as follows: Figure 5 shown. Through this chip, each of the 4 samples to be tested can be divided into 4 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com