Non-pollution directional solidification method of high-niobium titanium aluminum intermetallic compound

An intermetallic compound and directional solidification technology is applied in the field of high-niobium-titanium-aluminum intermetallic compound materials, which can solve the problems affecting the performance of high-niobium-titanium-aluminum alloy, the performance degradation of high-niobium-titanium-aluminum alloy, and the pollution of high-niobium-titanium-aluminum alloy. Achieve the effect of low cost, improved tensile strength and high unidirectional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

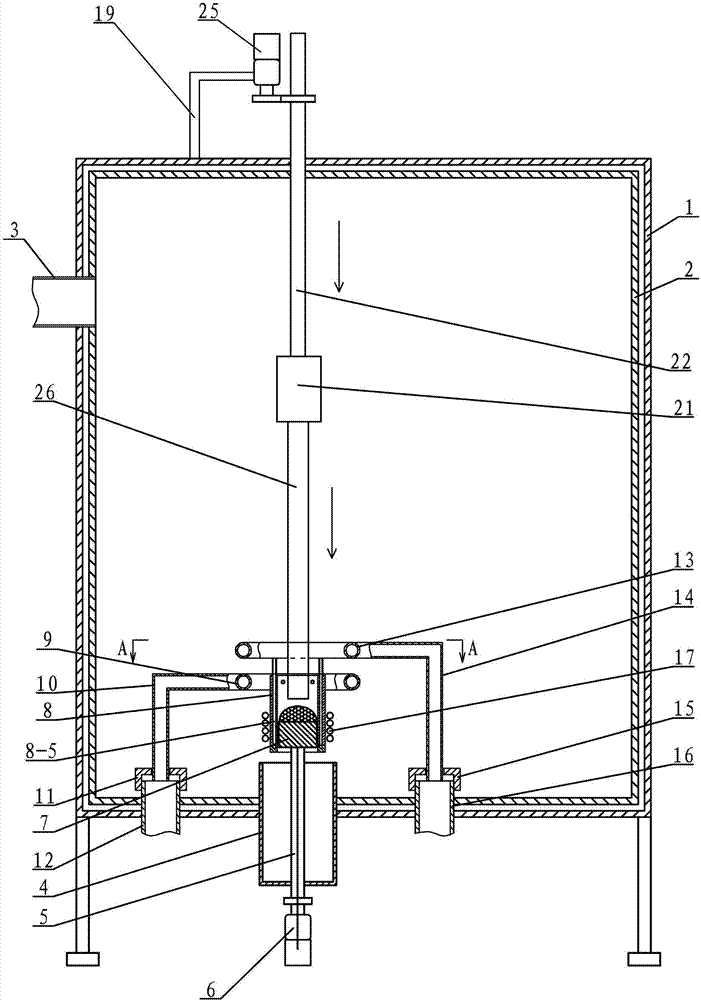

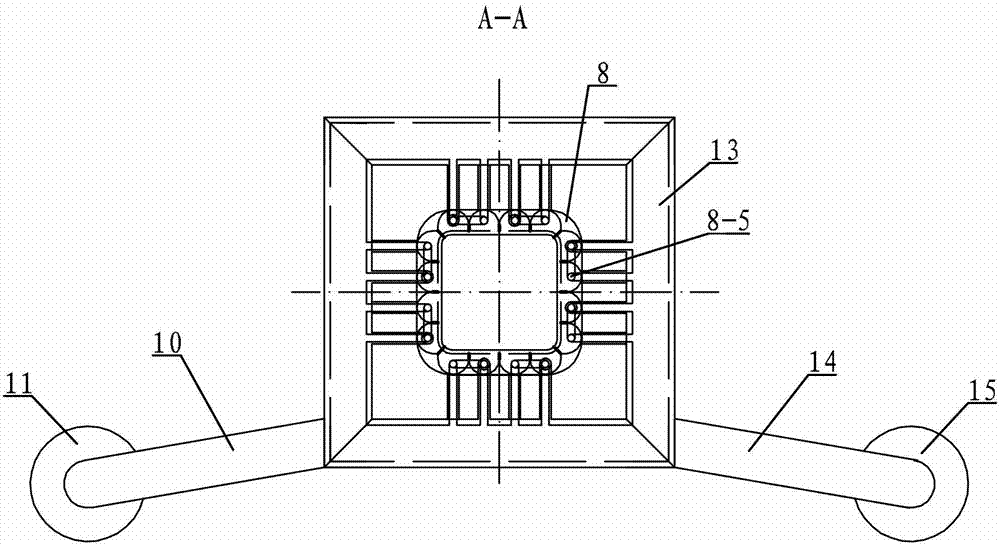

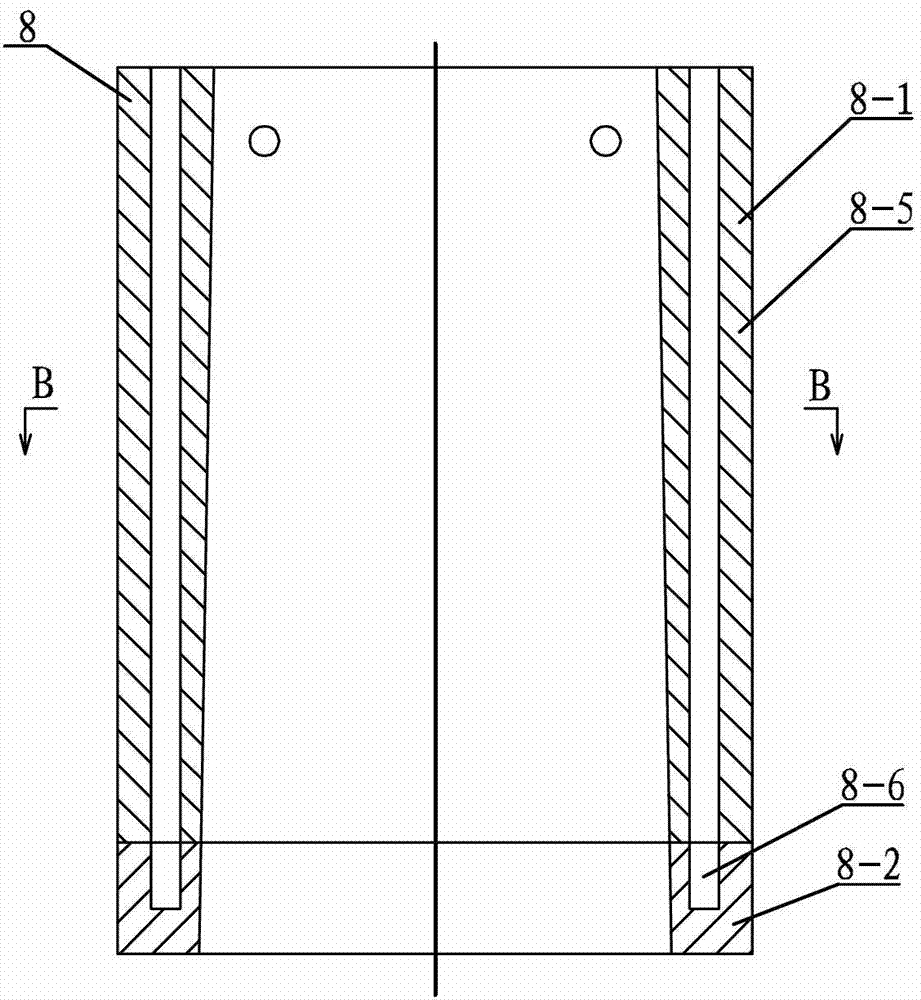

[0019] Specific implementation mode one: combine Figure 1~5 To illustrate this embodiment, the pollution-free directional solidification method of a high-niobium-titanium-aluminum intermetallic compound described in this embodiment is realized through the following steps:

[0020] A. Electromagnetic induction heating process:

[0021] Step A1, the upper end surface of the high-niobium titanium-aluminum alloy base 7 is set at a distance of 53 mm to 55 mm from the upper end surface of the electromagnetic copper crucible 8, and the raw material rod 26 is hung above the electromagnetic copper crucible 8 through the feeding rod 22, and extended into the inside of the crucible 43 ~45mm;

[0022] Step A2, using the vacuum pump 3 to evacuate the vacuum chamber 2 equipped with the electromagnetic copper crucible 8, so that the vacuum degree of the vacuum chamber 2 is 0.8Pa~1.0Pa;

[0023] Step A3, filling the vacuum chamber 2 with argon gas of 350-400 Pa;

[0024] Step A4, pass sin...

specific Embodiment approach 2

[0032] Embodiment 2: In this embodiment, in step A4, the initial power supply is controlled to be 42kW. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific implementation mode three: In this implementation mode, in step B2, after the hump height in the electromagnetic copper crucible 8 reaches 13 to 18 mm, the temperature is kept for 8 to 10 minutes. After heat preservation, the temperature field of the melt can have a certain degree of superheat and reach the initial steady state, and the volume of the hump can also be stabilized. Other steps are the same as those in Embodiment 1 or 2.

[0034] Carry out following elaboration again for the inventive method:

[0035] The method of the present invention is realized by three processes of induction heating, electromagnetic confinement and columnar crystal growth; in terms of induction heating, the high-niobium titanium aluminum alloy base and feeding rod are heated by electromagnetic induction until melting; in terms of electromagnetic confinement, the high-frequency magnetic field induces the raw materials Melting and forming a hump, the height of the hump is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com