Valve manufacturing process for improving impact toughness of F92 butt welding heat affected area

A technology of impact toughness and heat-affected zone, which is applied in the field of valve manufacturing technology to improve the impact toughness of F92 butt welding heat-affected zone, can solve the problems of low effect and low impact toughness, and achieve the effect of improving dispersion and improving inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The heat treatment process in the present invention mainly includes forging→post-forging heat treatment→rough machining→butt welding→performance heat treatment→secondary tempering→surfacing welding sealing surface→post-welding heat treatment→finishing→inspection.

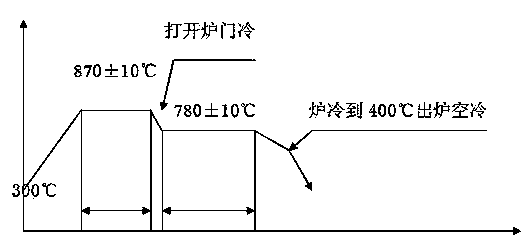

[0011] Heat treatment after forging: heat the forged piece in the furnace to 870±10°C, keep it warm for 2-4 hours, open the furnace door and cool it to 780±10°C, keep it warm for 1-2 hours, cool the furnace to 400°C and take it out of the furnace for air cooling.

[0012] Process purpose:

[0013] a. To spheroidize alloy carbides and improve the dispersion of alloy carbides;

[0014] b. Guarantee cutting performance;

[0015] c. Prepare the tissue for butt welding.

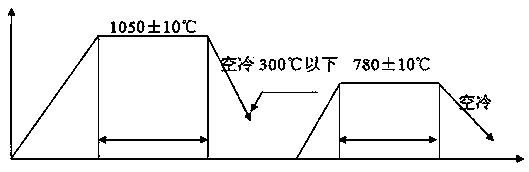

[0016] Performance heat treatment: heat in the furnace to 1050±10°C, keep warm for 2-4 hours, air cool below 300°C; reheat to 780±10°C, keep warm for 4-5 hours, then air-cool.

[0017] Process purpose:

[0018] a. Meet the mechanical performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com