Fe-hydrogenase model compound, its preparation method, photo-catalytic hydrogen production system containing it, and hydrogen preparation method of system

A technology of simulating compounds and iron hydrogenase, which is applied in the direction of iron organic compounds, organic compound/hydride/coordination complex catalysts, hydrogen production, etc., can solve the problems of loss of catalytic activity, catalyst instability, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

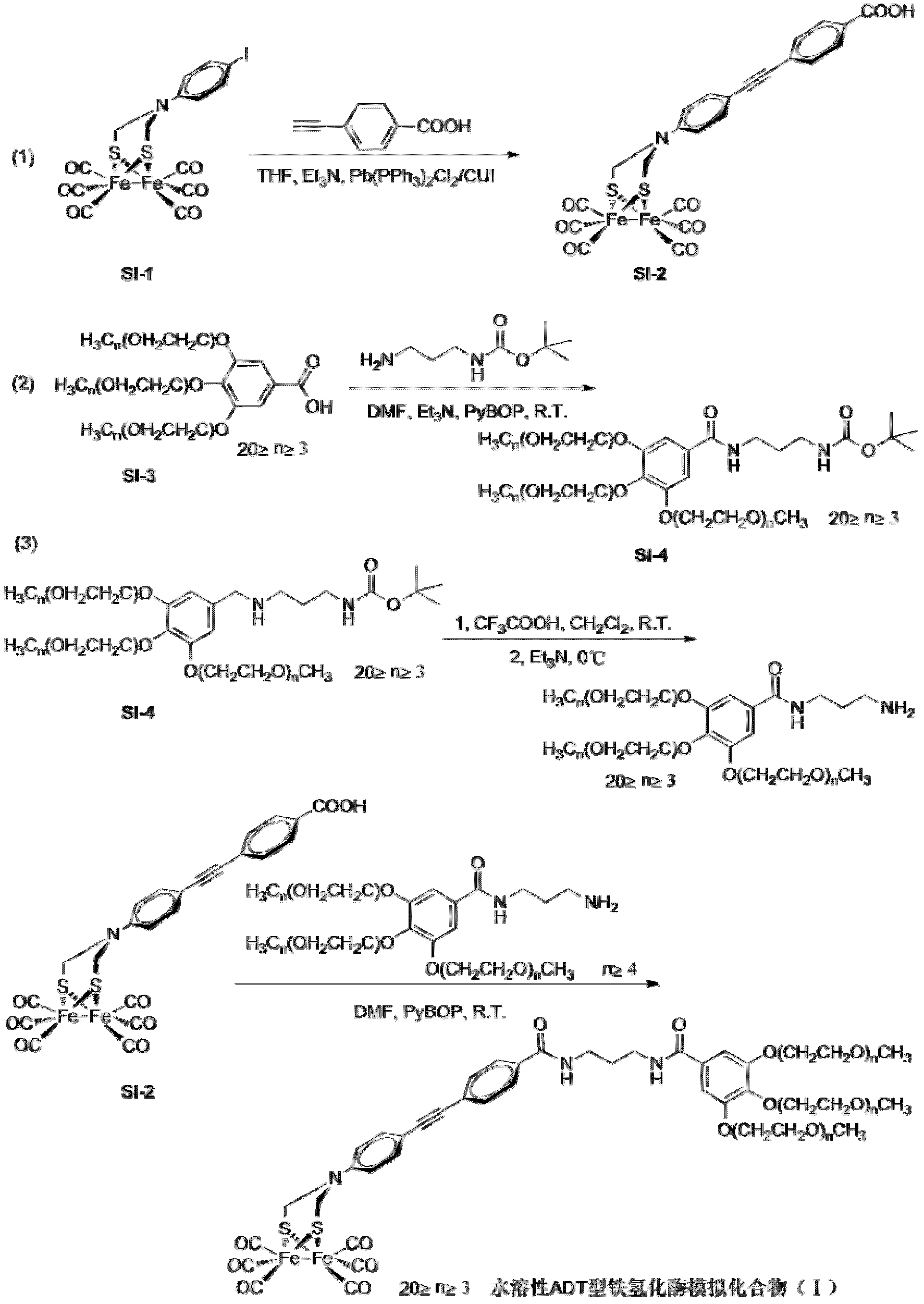

[0130] Preparation of water-soluble ADT type iron hydrogenase mimetic compound (I), such as figure 1 The synthetic roadmap shown, wherein n=3 of SI-3, comprises the following steps:

[0131] 1) Add 0.6g C 14 h 8 Fe 2 INO 6 S 2 (hereinafter referred to as SI-1) and 0.15g of 4-ethynylbenzoic acid were dissolved in 20ml of tetrahydrofuran, then added 7ml of anhydrous triethylamine, degassed with argon for 25 minutes, and added 0.015g of Pd(PPh 3 ) 2 Cl 2 and 0.008g CuI, refluxed for 5 hours, after monitoring the completion of the reaction, separated with a silica gel column, rinsed with a mixed solution of methanol / dichloromethane=1 / 10 (v / v) to obtain the product SI-2;

[0132] 2) Add 7.50g of SI-3, 2.55g of propylenediamine protected by tert-butoxycarbonyl (hereinafter referred to as: Boc) at one end, and 7.75g of benzotriazol-1-yl-oxy hexafluorophosphate in 45ml of DMF Tripyrrolidinyl phosphorus (hereinafter referred to as: PyBOP) and 18ml triethylamine, stirred the mix...

Embodiment 2

[0137] Preparation of water-soluble ADT type iron hydrogenase mimetic compound (I), such as figure 1 The synthetic roadmap shown, wherein n=3 of SI-3, comprises the following steps:

[0138] 1) Dissolve 0.6g SI-1 and 0.15g 4-ethynylbenzoic acid in 30ml tetrahydrofuran, then add 9ml anhydrous triethylamine, degas with argon for 50 minutes, add 0.020g Pd(PPh 3 ) 2 Cl 2 and 0.010g CuI, refluxed for 7 hours, after monitoring the completion of the reaction, separated with a silica gel column, rinsed with a mixed solution of methanol / dichloromethane=1 / 10 (v / v) to obtain the product SI-2;

[0139] 2) Add 7.70g SI-3, 2.65g propylenediamine protected by Boc at one end, 7.80g PyBOP and 22ml triethylamine in 55ml DMF, stir the mixture at room temperature for 3 hours, then pour the mixture into 160ml water, and use Dichloromethane extracted 4 times, kept the organic layer, and then extracted 9 times with saturated brine to remove DMF in the mixed system, kept the organic layer, added N...

Embodiment 3

[0142] Same as Example 1, the only difference is that n=4 in SI-3, and the consumption of SI-3 is 10.6g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com