Insoluble polymeric quaternary ammonium salt bactericide, preparation method thereof and sterilization packed bed

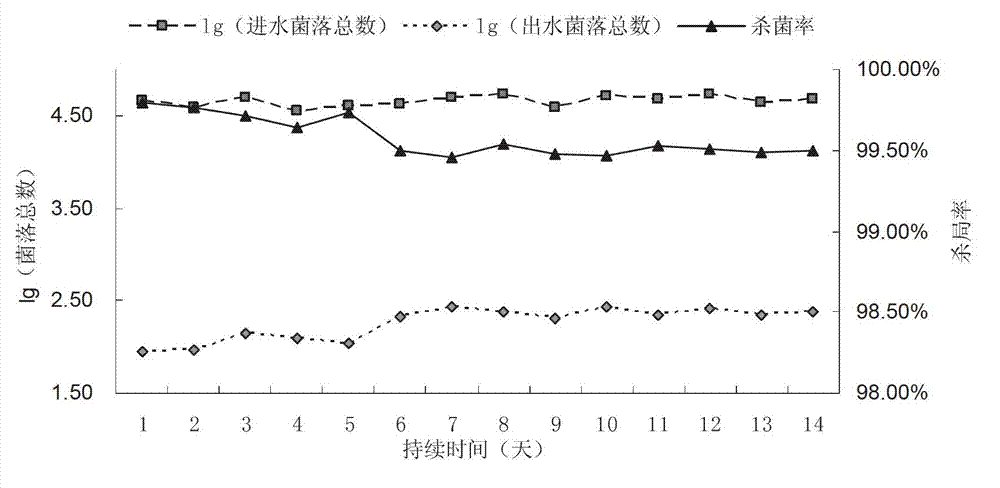

A technology of quaternary ammonium salts and fungicides, applied in the field of fungicides and their preparation, can solve the problems of easy foaming, secondary pollution of water bodies, poor reusability, etc., and achieves stable effects, good sterilization performance and short sterilization time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0032] Soak and wash the sulfonic acid cationic resin with absolute ethanol and 30% dilute sulfuric acid, react with 95% ethanol at 30°C for 24 hours, then add pyridine to make the mass / volume of resin, volume percentage 95% ethanol and pyridine ( g / ml) ratio of 1:5:3, stirred for 8h. The resin was then filtered off, washed repeatedly with 95% ethanol, and dried in vacuo. Then resin:thionyl chloride was stirred at 70°C for 8 hours at a mass / volume (g / ml) ratio of 1:3. After the reaction, the resin was filtered out, washed repeatedly with deionized water, and dried in vacuum.

[0033] The resin, isobutanol and polyethyleneimine were reacted at room temperature for 24 hours at a mass / volume (g / ml) ratio of 1:8:3 to obtain a PI resin system. Then add 1-bromohexane with a weight / volume (g / ml) ratio of 1:1 (1-bromohexane:resin) to the PI resin system obtained after the above reaction, and react at 70°C for 24 h. Continue to add methyl iodide with a weight / volume (g / ml) ratio of ...

preparation example 2

[0035]Soak and wash the sulfonic acid cationic resin with absolute ethanol and 30% dilute sulfuric acid, and react with 95% ethanol at a constant temperature of 50°C for 36 hours, then add pyridine to make the mass / volume of resin, 95% ethanol and pyridine ( g / ml) ratio of 1:6:4, stirred for 10h. The resin was then filtered off, washed repeatedly with 95% ethanol, and dried in vacuo. Then resin:thionyl chloride was stirred at 80°C for 10 h at a mass / volume (g / ml) ratio of 1:4. After the reaction, the resin was filtered out, washed repeatedly with deionized water, and dried in vacuum.

[0036] The resin, isobutanol and polyethyleneimine were reacted at room temperature for 36 h at a mass / volume (g / ml) ratio of 1:10:4. Then add 1-bromohexane to the resin weight / volume (g / ml) ratio of 1:2 (1-bromohexane:resin) to the above reacted solution, and react at 80°C for 36h. Continue to add methyl iodide with a weight / volume (g / ml) ratio of 1:1 (methyl iodide:resin) to the resin, reac...

preparation example 3

[0038] Soak and wash the sulfonic acid cationic resin with absolute ethanol and 30% dilute sulfuric acid, and react with 95% ethanol at a constant temperature of 40°C for 24 hours, then add pyridine to make the mass / volume of the resin, 95% ethanol and pyridine ( g / ml) ratio of 1:8:6, stirred for 12h. The resin was then filtered off, washed repeatedly with 95% ethanol, and dried in vacuo. Then resin:thionyl chloride was stirred at 90°C for 12h at a mass / volume (g / ml) ratio of 1:6. After the reaction, the resin was filtered out, washed repeatedly with deionized water, and dried in vacuum.

[0039] The resin, isobutanol and polyethyleneimine were reacted at room temperature for 48h at a mass / volume (g / ml) ratio of 1:9:6. Then add 1-bromohexane with resin weight / volume (g / ml) ratio of 1:3 (1-bromohexane:resin) to the above reacted solution, and react at 90°C for 48h. Continue to add methyl iodide with a weight / volume (g / ml) ratio of 1:2 (methyl iodide:resin) to the resin, reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com