Manufacturing method for Nb3Al superconducting wire

A kind of superconducting wire, technology of making method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a kind of Nb 3 The method for manufacturing an Al superconducting wire includes: preparing a supersaturated solid solution, powder processing, tube loading and drawing, and phase forming heat treatment. The specific steps are as follows:

[0023] a. Preparation of supersaturated solid solution: take 1.0kg Al 1-x Nb x Master alloy (x=0.251) ingot and 4.26kg Nb ingot are melted and mixed uniformly by arc melting; then, slowly cooled to 1940°C, the high-temperature Nb-Al solid solution is directly put into gallium liquid for quenching , to obtain Nb(Al)ss supersaturated solid solution;

[0024] b. Powder processing: crush the obtained Nb(Al)ss supersaturated solid solution by impact and rolling; and process the crushed Nb(Al)ss supersaturated solid solution into particle size by high-energy ball milling 100 mesh Nb(Al)ss supersaturated solid solution powder;

[0025] c. Tube drawing: put the obtained Nb(Al)ss supersaturated solid solution powder into a Cu...

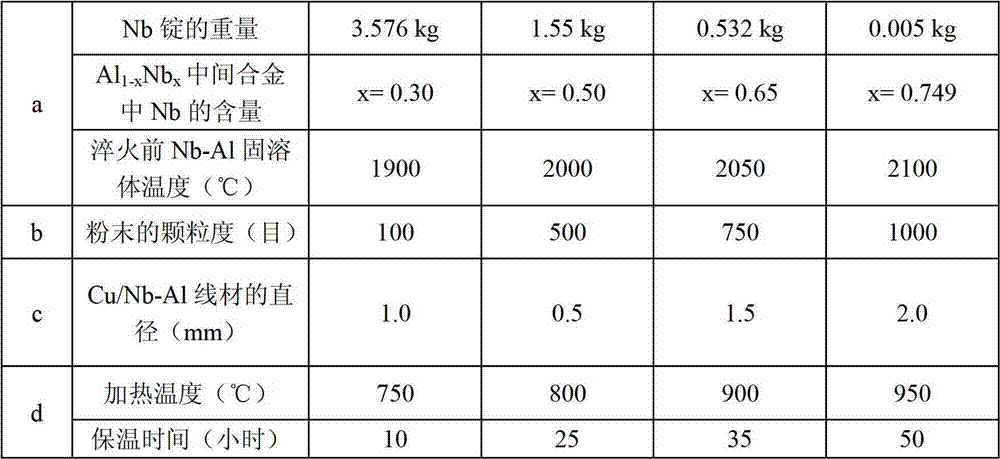

Embodiment 2-5

[0028] Embodiment 2-5, a kind of Nb 3 The specific steps of the manufacturing method of the Al superconducting wire are the same as in Example 1, and the relevant parameters are shown in Table 1 below.

[0029] Table 1 Embodiment 2-5 related parameters

[0030]

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com