Thin-film photovoltaic devices using enhanced light-harvesting schemes

A device and light absorption technology, applied in photovoltaic power generation, semiconductor devices, electrical components, etc., to achieve the effect of saving deposition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

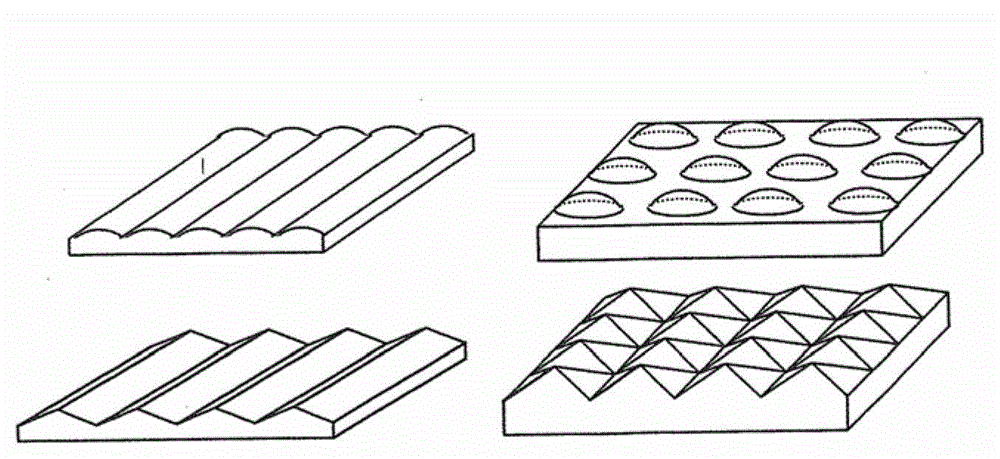

[0040] produces a polymer plate, which includes such as Figure 4 An array of structures as described in . Thin-film silicon modules based on a tandem junction cell structure with two light-absorbing active layers and an upper cell consisting of amorphous silicon and a bottom cell consisting of microcrystalline silicon were fabricated. The TCO in the module is based on a non-textured 50nm thick aluminum-doped zinc oxide layer. Silver was used as the reflective back electrode. The polymer sheet was applied to the glass front cladding of the thin film silicon module by lamination with a sheet of EVA.

example 2

[0042] produce polymer sheets, which include such as Figure 4 An array of structures as described in . Thin-film silicon modules based on a tandem junction cell structure with two light-absorbing active layers and an upper cell consisting of amorphous silicon and a bottom cell consisting of microcrystalline silicon were fabricated. The TCO in the module is based on a non-textured 50nm thick aluminum-doped zinc oxide layer. Silver was used as the reflective back electrode. The polymer sheet is applied to the glass front cladding of the thin-film silicon module by a silicone-based adhesive.

example 3

[0044] produces a polymer plate, which includes such as Figure 4 An array of structures as described in . Fabrication of thin-film silicon modules based on -Si / μc-Si based photovoltaic modules including textured superstrate, non-textured 100-400nm ZnO, 150-200nm a-Si i-layer, 500-800nm μc -Si i-layer. Silver was used as the reflective back electrode. The polymer plate is applied to the glass front cladding of the thin film silicon module by using a polymer adhesive.

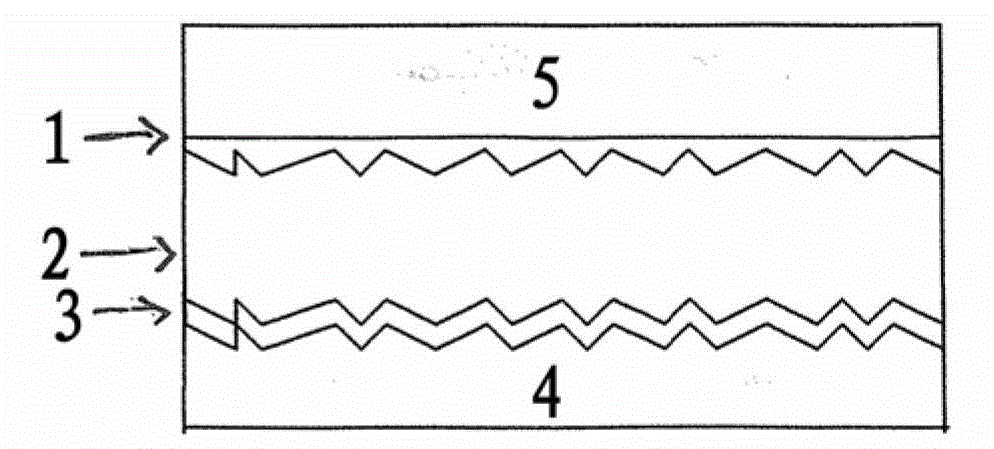

[0045] figure 1 :

[0046] figure 1 Methods of reducing the layer thickness of the active material or active layer 2 according to the prior art are shown. The purpose of this is to create a texture of refracted light in the front electrode or TCO1. As a result of the refraction of light, the path length of light entering the active material 2 increases. However, the control of the refraction of light is limited and thus the increase in path length is small. Also, texturing introduces defects in TCO1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com