Preparation method for high stability mesoporous molecular sieve under ionothermal system

An ionic liquid and ionic technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of poor hydrothermal stability, environmental pollution, and the production of a large amount of waste acid or lye, and achieve stable performance, extended application range, and thermal stability. The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

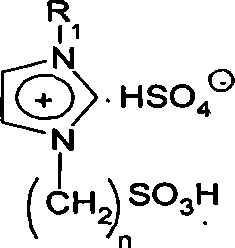

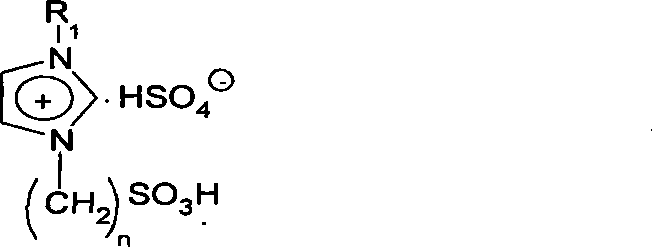

Embodiment 1

[0020] 0.3 g sodium metaaluminate, 6.69 g silica solution (30%), 0.568 g sodium silicate, 5 g acid functionalized ionic liquid 1-methyl-3-(3-sulfopropyl)imidazole hydrogen sulfate salt, mixed in a reaction kettle, and then crystallized at 140°C for 4 hours, and then added acid-functionalized ionic liquid 1-methyl-3-(3-sulfopropyl)imidazole hydrogen sulfate to the solution after crystallization 20 grams of salt and 4 grams of P123 were mixed and stirred at 40°C for 20 hours. The crystallized mixed solution was crystallized at 100°C for 24 hours. After crystallization, cool to room temperature, add deionized water to dilute and wash, filter with suction, dry the powder at 60°C for 24 hours, and roast at 550°C for 6 hours to obtain the product.

Embodiment 2

[0022] 0.3 g sodium metaaluminate, 6.69 g silica solution (30%), 0.568 g sodium silicate, 5 g acid functionalized ionic liquid 1-ethyl-3-(3-sulfopropyl)imidazole hydrogen sulfate salt, mixed in a reaction kettle, and then crystallized at 120°C for 4 hours, and then added acid-functionalized ionic liquid 1-ethyl-3-(3-sulfopropyl) imidazole sulfuric acid to the solution after crystallization 20 grams of hydrogen salt and 4 grams of P123 were mixed and stirred at 50°C for 20 hours. Crystallization at 100°C for 24 hours. After crystallization, cool to room temperature, add deionized water to dilute and wash, filter with suction, dry the powder at 60°C for 20 hours, and roast at 600°C for 7 hours to obtain the product.

Embodiment 3

[0024] 0.3 g sodium metaaluminate, 13.92 g silica solution (30%), 1.14 g sodium silicate, 10 g acid functionalized ionic liquid 1-ethyl-3-(3-sulfobutyl)imidazole hydrogen sulfate Mix the salts in a reaction kettle, then crystallize at 130°C for 5 hours, cool to room temperature, and then add acid-functionalized ionic liquid 1-ethyl-3-(3-sulfobutyl) to the solution after crystallization Mix 45 g of imidazolium bisulfate and 4 g of P123 and stir at 40°C for 20 hours. Crystallization at 100°C for 24 hours. After crystallization, cool to room temperature, add deionized water to dilute and wash, filter with suction, dry the powder at 60°C for 12 hours, and roast at 550°C for 7 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com