Mesoporous calcium carbonate nanoparticles, preparation method thereof and composite material

A nanoparticle and calcium carbonate technology, applied in the field of material science, can solve the problems of difficulty in forming calcium carbonate nanoparticles with mesoporous structure, inability to create strong organic/inorganic interaction force, etc., and achieve the effect of promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of above-mentioned mesoporous calcium carbonate nanoparticle, comprises the steps:

[0040] (a) Dissolve the calcium chloride donor completely in an organic solvent, then add an etchant, and mix well to obtain solution I 1 , the solution I 1 Contains calcium chloride, etchant and a small amount of water;

[0041] (b) will be fitted with I1 The open container is placed in the airtight container that ammonium bicarbonate is housed, and ammonium bicarbonate is excessive in the reaction process, and standing reaction 3~10 days obtains reactant I 2 ;

[0042] (c) will I 2 Centrifugation, washing and drying are carried out successively to obtain the product I 3 ;

[0043] The calcium chloride donor consists of water and calcium chloride;

[0044] The organic solvent is selected from polar solvents and protic solvents.

[0045] The calcium chloride donor is completely dissolved in a reaction flask contain...

Embodiment 1

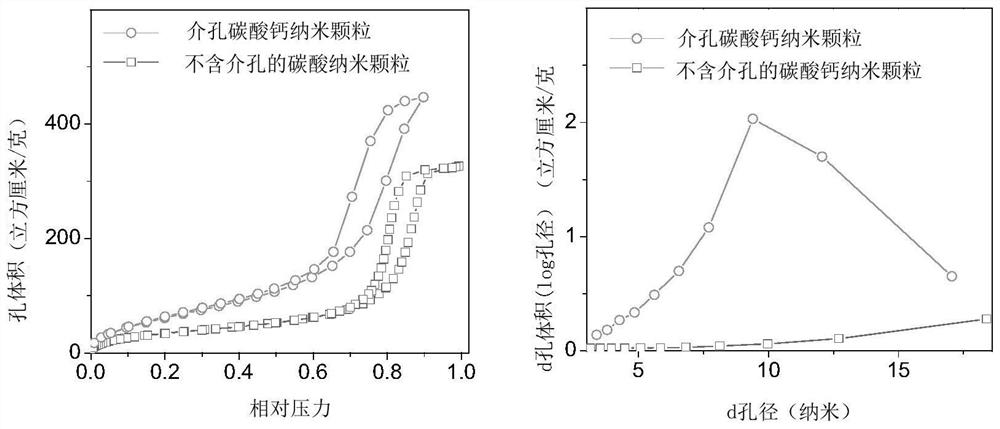

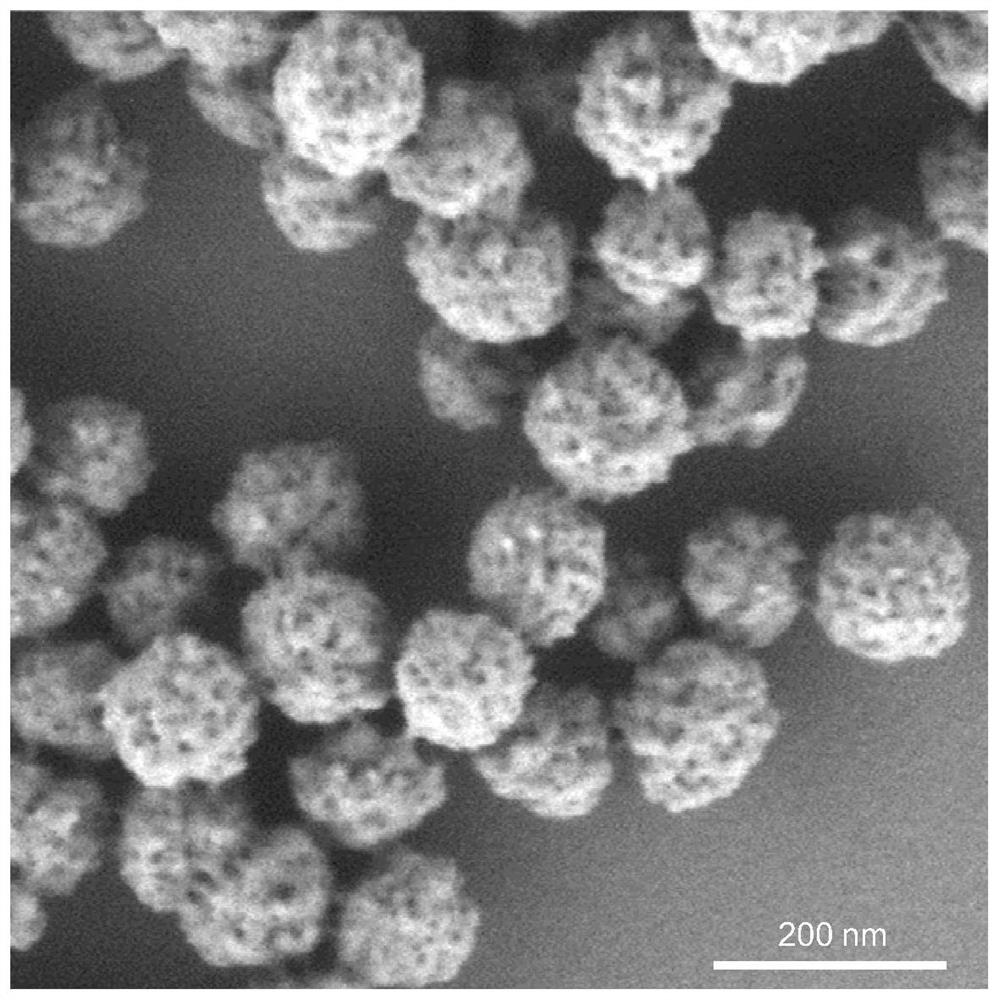

[0066] Embodiment 1: Preparation of mesoporous calcium carbonate nanoparticles

[0067] Materials: calcium chloride dihydrate; absolute ethanol; triethyl phosphate; ammonium bicarbonate particles; reaction bottle; airtight container; sealing film.

[0068] Completely dissolve 29.4mg of calcium chloride dihydrate in 40mL of absolute ethanol, place in a 50mL reaction bottle, then add 20μL of triethyl phosphate, mix well, and obtain solution I 1 , use a parafilm to seal the reaction bottle, and pierce 6 holes on the film; then place the reaction bottle in an airtight container covered with ammonium bicarbonate particles, and leave it at room temperature for 7 days to obtain the reaction solution I 2 ; to reaction solution I 2 Carry out centrifugation to obtain calcium carbonate nanoparticles with a mesoporous structure, then wash with absolute ethanol and dry in an oven to obtain the final product I 3 , and finally the I 3 Store in 40mL of absolute ethanol, and keep in a water...

Embodiment 2

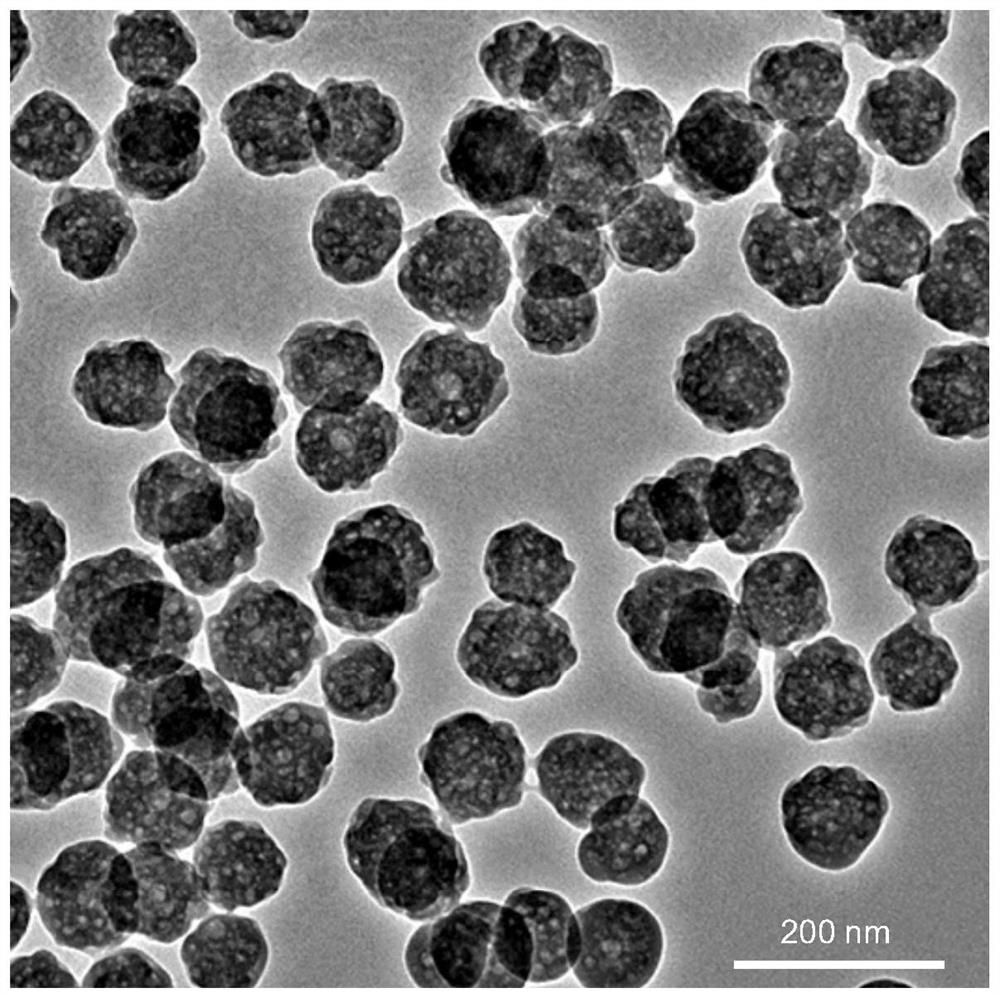

[0070] Embodiment 2: Mesoporous calcium carbonate nanoparticles and polymer form composite material

[0071] Material: final product I synthesized in Example 1 3 PHBV (polyhydroxybutyrate valeric acid copolyester); Chloroform; Liquid nitrogen dish; Deionized water; Synthesized calcium carbonate nanoparticles without adding triethyl phosphate in embodiment 2;

[0072] Synthetic mesoporous calcium carbonate nanoparticles (i.e. final product I) in 15mg embodiment 1 3 ) was dispersed in 1 mL of chloroform, 75 mg of PHBV (polyhydroxybutyrate copolyester) polymer was completely dissolved in 2 mL of chloroform, and then the above two solutions were uniformly mixed to obtain mixed solution II 1 ; the mixture II 1Pour it into a 7cm×3cm×3cm smooth stainless steel mold and wrap it with tinfoil paper. Put the mold into the liquid nitrogen dish quickly and make sure that the mold is in a horizontal state; then quickly transfer the liquid nitrogen dish with the mold to room temperature an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com