Application of transition metallic composite oxide catalyst in catalytic oxidation of methylbenzene to synthesize benzyl benzoate

A composite oxide, benzyl benzoate technology, applied in physical/chemical process catalysts, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve the problems of high cost, many reaction by-products, harsh reaction conditions, etc. The effect of low cost, high selectivity and activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare the transition metal composite oxide catalyst, comprising the steps of:

[0031] 1) Take 20 mol of calcium hydroxide, 6 mol of chromium hydroxide, 3 mol of ammonium bromide and 3 mol of ammonium fluoride to make 10L of colloid;

[0032] 2) Put the obtained colloidal solution into the autoclave and stir for 24 hours, the temperature is controlled at 150 °C to obtain the required colloid, then add 1.0 g of chromium dichloride to the colloid, continue the reaction for 6 hours, and the temperature is controlled at 80 °C , and then filter or centrifugally dehydrate the obtained colloid, wash with water until neutral, and dry at 100°C for 12 hours;

[0033] 3) Place the resulting solid sample in NH 3 Calcined in a tube furnace for 6 hours with the temperature controlled at 400 °C to obtain the desired catalyst.

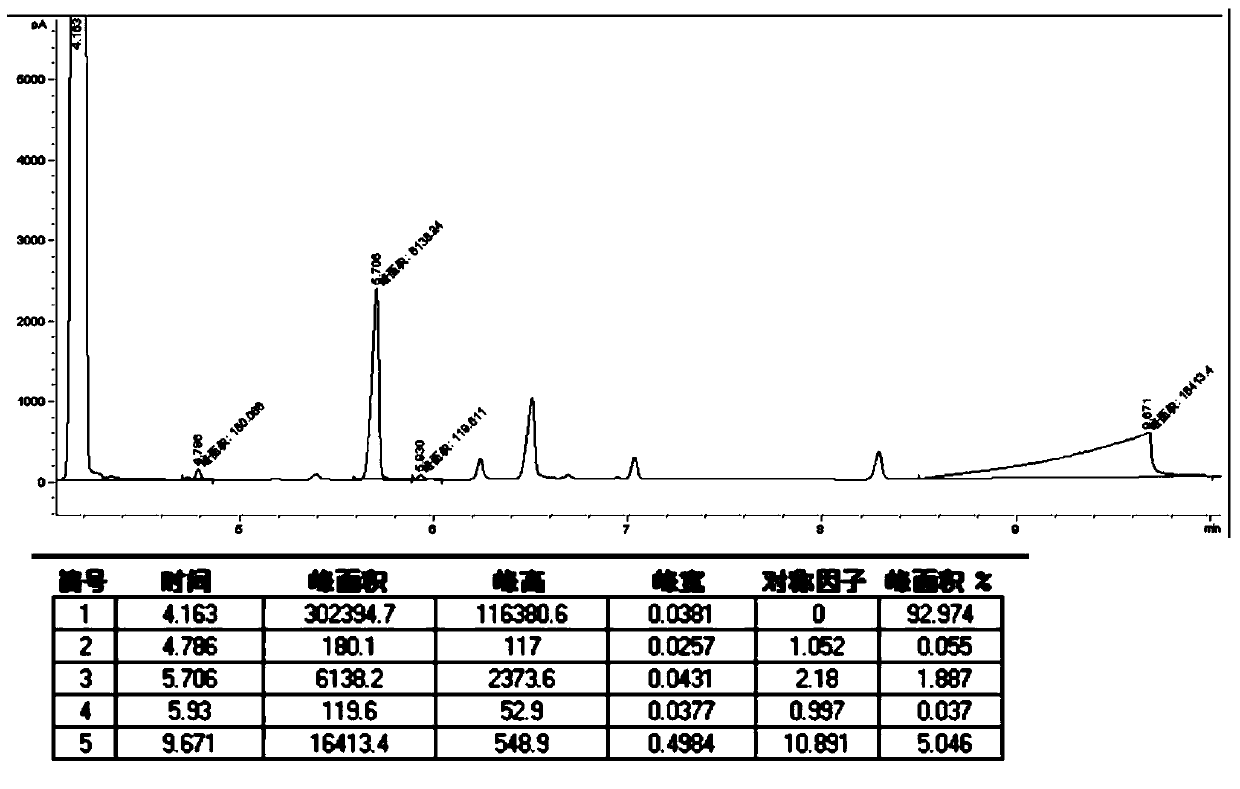

[0034] Utilize the prepared catalyst to catalyze the oxidation of toluene to synthesize benzyl benzoate, and the reaction conditions are gentle, comprising...

Embodiment 2

[0037] Prepare the transition metal composite oxide catalyst, comprising the steps of:

[0038] 1) Take 6 mol of barium hydroxide, 2 mol of ferric hydroxide, and another 1 mol of ammonium chloride and 1 mol of ammonium iodide to make 1.8 L of colloid;

[0039] 2) Put the obtained colloidal solution into an autoclave and stir for 36 hours. The temperature is controlled at 140°C to obtain the desired colloid. Then add 0.6 g of manganese acetate to the colloid and continue the reaction for 10 hours. The temperature is controlled at 100°C. Filter or centrifuge the obtained colloid, wash with water until neutral, and dry at 120°C for 24 hours;

[0040] 3) Place the resulting solid sample in H 2 Calcined in a tube furnace for 10 hours with the temperature controlled at 800 °C to obtain the desired catalyst.

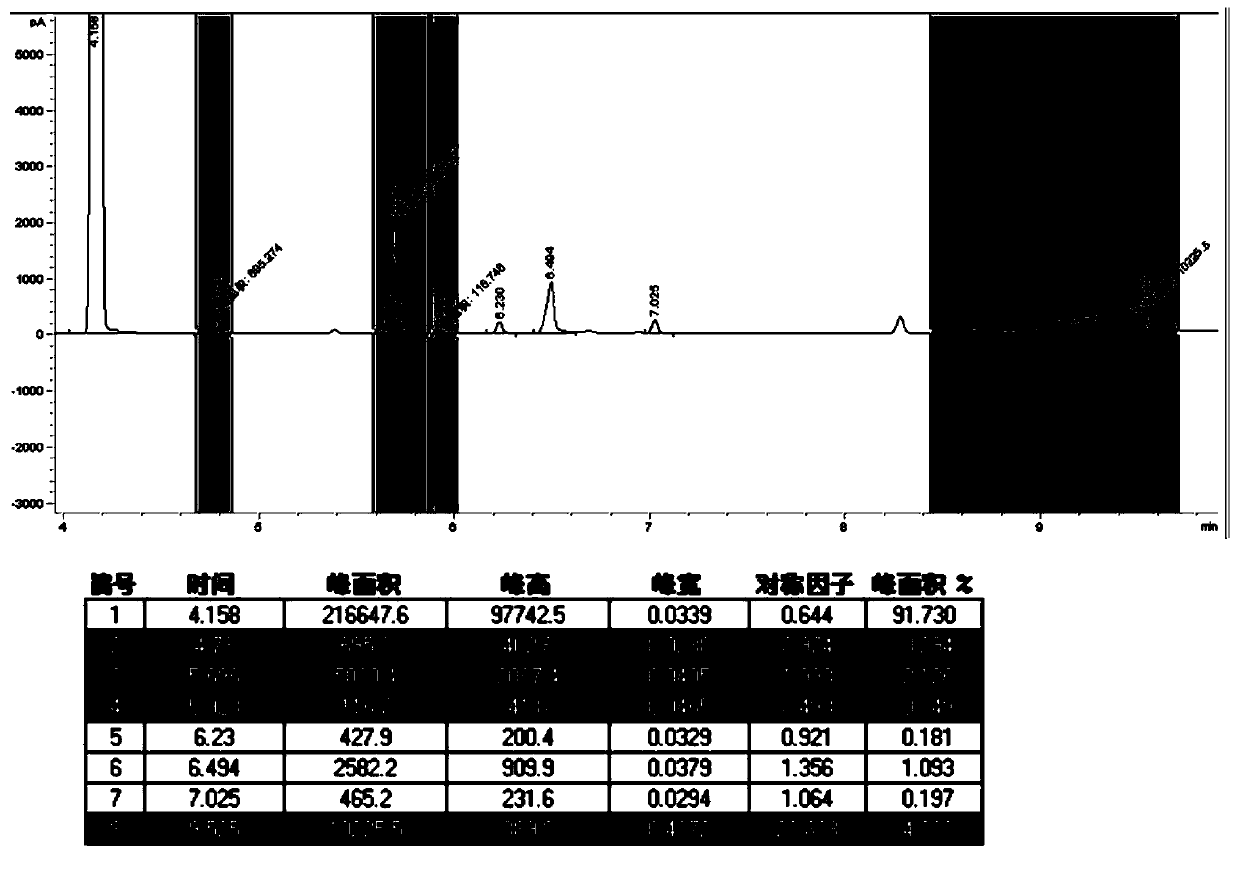

[0041] Utilize the prepared catalyst to catalyze the oxidation of toluene to synthesize benzyl benzoate, and the reaction conditions are gentle, comprising the steps:

[004...

Embodiment 3

[0044] Prepare the transition metal composite oxide catalyst, comprising the steps of:

[0045] 1) Take 9 mol of barium hydroxide, 4.5 mol of aluminum hydroxide, and another 4.5 mol of ammonium fluoride to make 3L of colloid;

[0046] 2) Put the obtained colloidal solution into the autoclave and stir for 12 hours. The temperature is controlled at 80°C to obtain the desired colloid. Then add 0.19 g of vanadium dichloride to the colloid and continue the reaction for 4 hours. The temperature is controlled at 25°C. , and then filter or centrifugally dehydrate the obtained colloid, wash with water until neutral, and dry at 80°C for 6 hours;

[0047] 3) The obtained solid sample was calcined in a tube furnace with CO for 3 hours, and the temperature was controlled at 350 °C to obtain the desired catalyst.

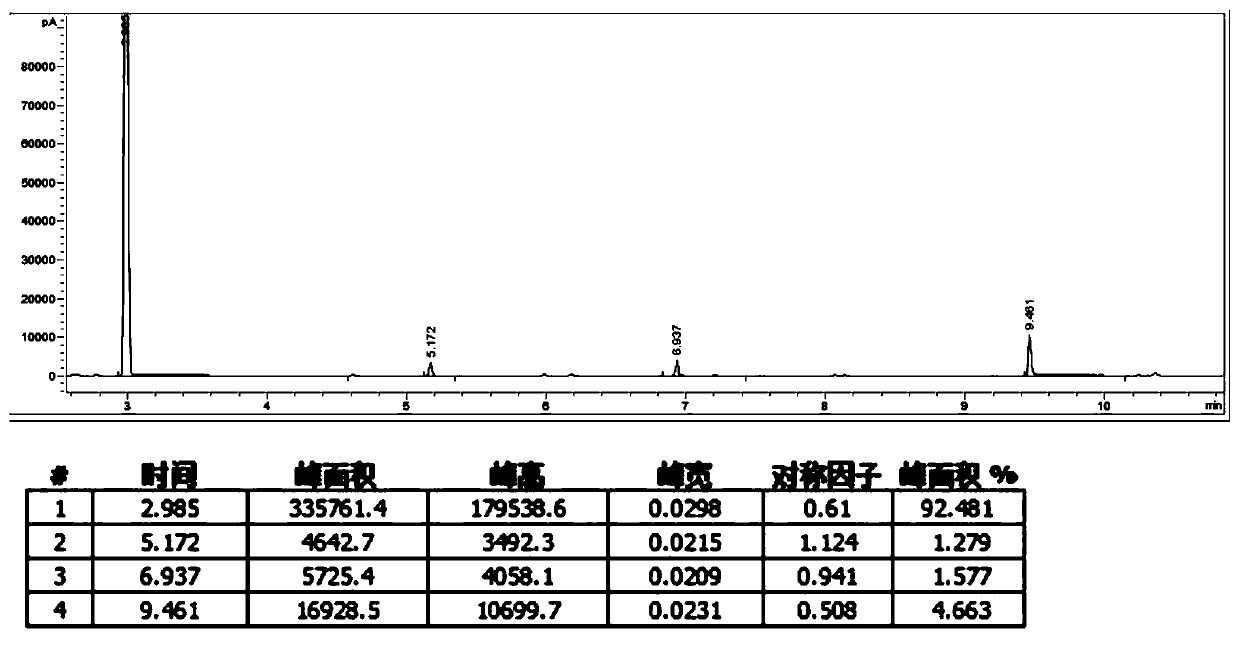

[0048] Utilize the prepared catalyst to catalyze the oxidation of toluene to synthesize benzyl benzoate, and the reaction conditions are gentle, comprising the steps:

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com