Preparation method of formed nitrogen-containing mesoporous carbon material

A technology of mesoporous carbon and preparation process, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as limiting the application scope of porous carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

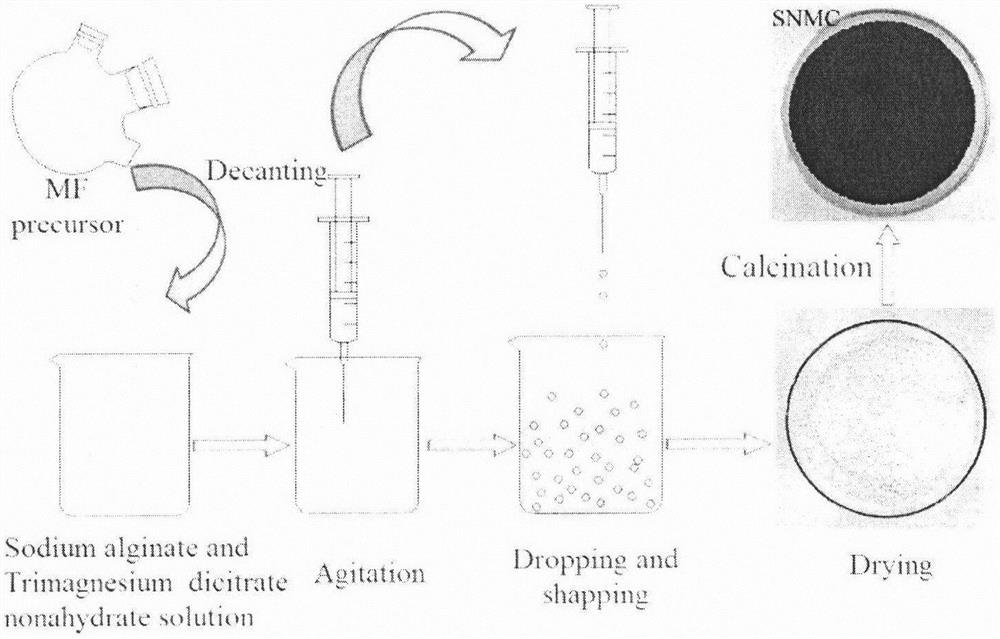

[0031] Embodiment 1: Small-scale test preparation process

[0032] The first step: the preparation of melamine resin prepolymer. Put 10.8g of melamine and 23.4g of formaldehyde aqueous solution (37wt%) in a 250mL three-necked flask, start stirring, add 60mL of 0.05mol / L sodium hydroxide aqueous solution, and then heat to 65°C for 0.5h. After the reaction is complete, naturally cool down to room temperature , to prepare a melamine resin prepolymer solution for use.

[0033] The second step: the drop ball method wrapping molding. Weigh 2.08g of sodium alginate and put it into a beaker, add 140g of water and stir, when the sodium alginate dissolves completely to form a sol, add 19.2g of magnesium citrate, continue to stir evenly, forming a milky white, opaque viscous liquid, and then add Wherein add the melamine resin prepolymer solution that the first step makes, after mixing uniformly, mixed solution is dripped in the 200g 4wt% calcium nitrate aqueous solution by syringe, and...

Embodiment 2

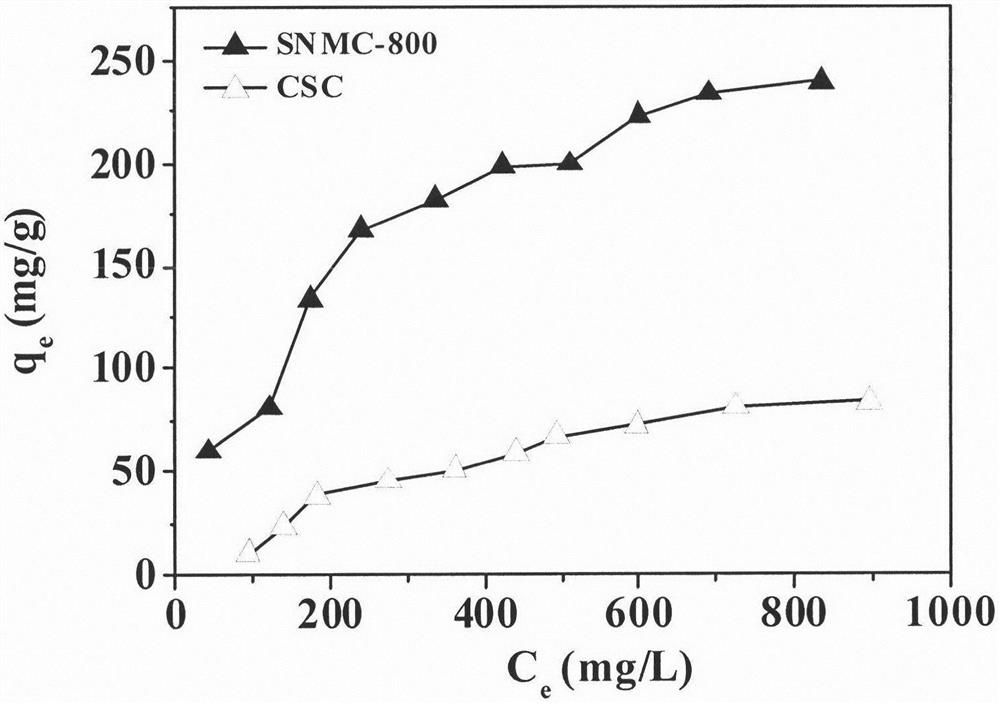

[0036] Example 2: Specific surface area and pore structure properties of carbon materials

[0037] The specific surface area and pore structure properties of the carbon material SNMC are shown in Table 1. As a comparison, we used the same method to test information such as the specific surface area of commercially available coconut shell carbon (referred to as CSC), and the results are listed in Table 1. As shown in Table 1, with the increase of calcination temperature, the specific surface area of carbon material SNMC showed a trend of first increasing and then decreasing, and the specific surface area was the highest at 800 °C, reaching 977m 2 / g. The change trend of the pore volume is the same as that of the specific surface area, and it is also the highest at 800 °C, reaching 0.85 cm 3 / g. The average pore diameter and the most probable pore diameter are not significantly affected by the calcination temperature, and they remain between 3.5-3.8nm and 3.3-3.6nm, respe...

Embodiment 3

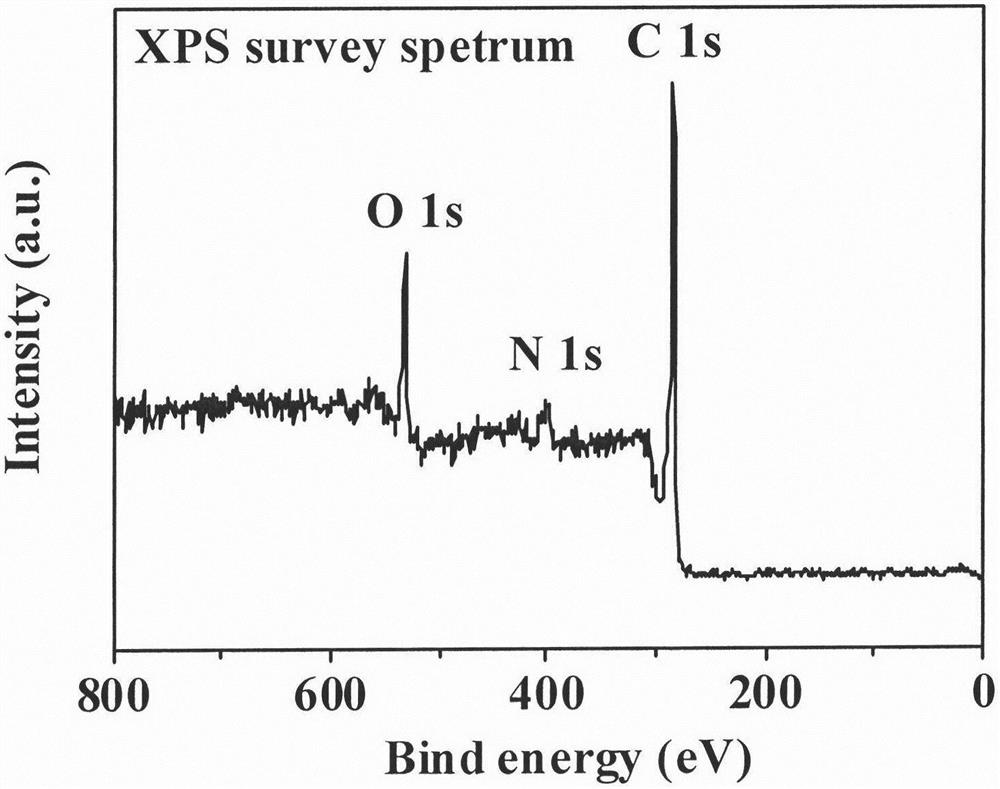

[0040] Example 3: Surface chemistry of carbon materials

[0041] The XPS spectrum of the carbon material SNMC-800 is attached figure 2 shown. attached by figure 2 It can be seen that nitrogen atoms and oxygen atoms have been successfully introduced into the carbon material SNMC, wherein the content of nitrogen atoms reaches 6.4% (N / C is about 0.08), and the content of oxygen atoms reaches 13.7% (O / C is about 0.17 ). Both nitrogen and oxygen atoms are electron-rich atoms, which can be used as anchor sites for noble metals, which is beneficial to improve the dispersion and stability of noble metals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com