Micro and nano-grade active light calcium carbonate automated production system

An active, lightweight, production system technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of affecting the health of operators, difficulty in large-scale production, and increasing production costs, so as to avoid heat loss, eliminate pollution, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

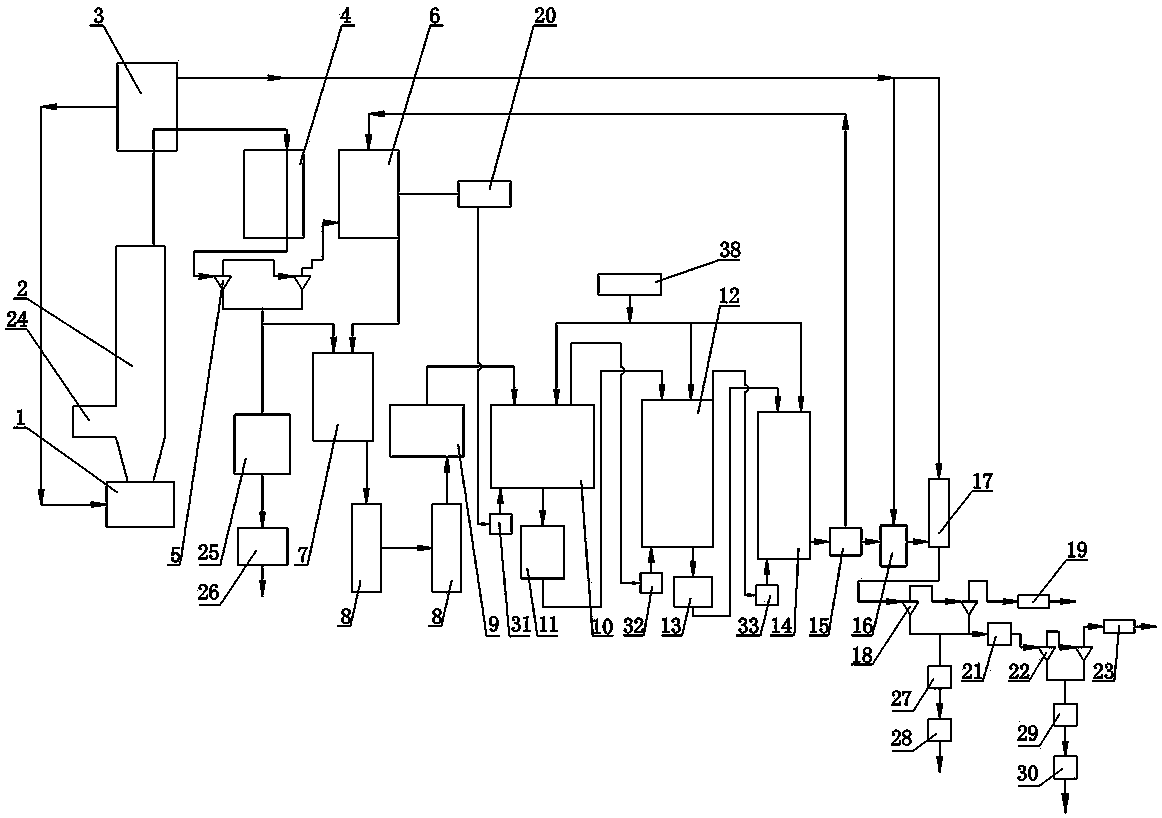

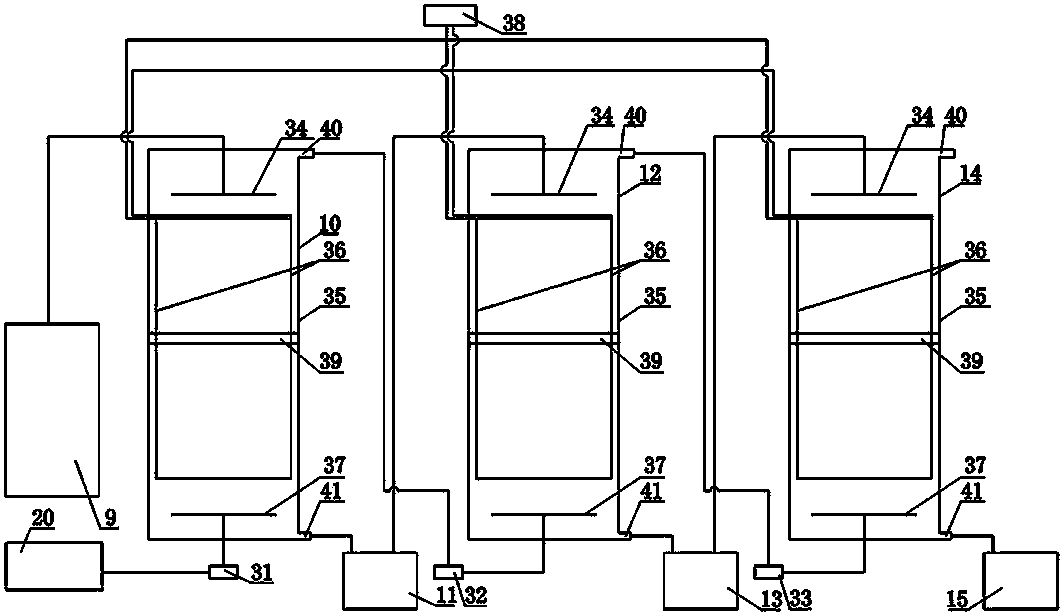

[0026] Such as figure 1As shown, the automatic production system of microfine and nanoscale active light calcium carbonate includes a feeding system 1, a burner 24, a calcination tower 2, a heat exchanger 3, a cooler A4, a cyclone separation device A5, a spray device 6, Carbon dioxide collection and addition system 20, emulsifier 7, static equipment 8, cooler B9, carbonization device, filter 15, dryer 16, dryer 17, cyclone separation device B18 and trap A19, such as figure 2 As shown, the carbonization device includes air compressor A31, carbonization machine A10, crystal particle size and dispersion processing system A11, air compressor B32, carbonization machine B12, crystal particle size and dispersion processing system B13, air compressor C33, carbonizer C14 and refrigerating machine 38, carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com