Continuous fiber reinforced thermoplastic resin prepreg tape and preparation method thereof

A technology of thermoplastic resin and enhanced thermoplasticity, applied in the field of thermoplastic resin prepreg tape and its preparation, can solve the problems of mechanical property degradation, matrix aging, etc., achieve high microwave absorption performance, improve competitiveness, and expand the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 32.2% polypropylene resin, 0.5% maleic anhydride grafted polypropylene compatibilizer, 0.2% tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]quaternary Tetrol ester (antioxidant 1010), 0.2% tris (2,4-di-tert-butylphenyl) phosphite (antioxidant 168), 0.3% ethylene-acrylic acid copolymer lubricant, 1.6% The ferrite absorbing material is mixed evenly in a high-speed mixer at room temperature and at a low speed for 70 seconds, and then pelletized in a twin-screw extruder. The processing temperature is 150-250°C, and the frequency of the extruder is 10Hz. Acrylic masterbatch.

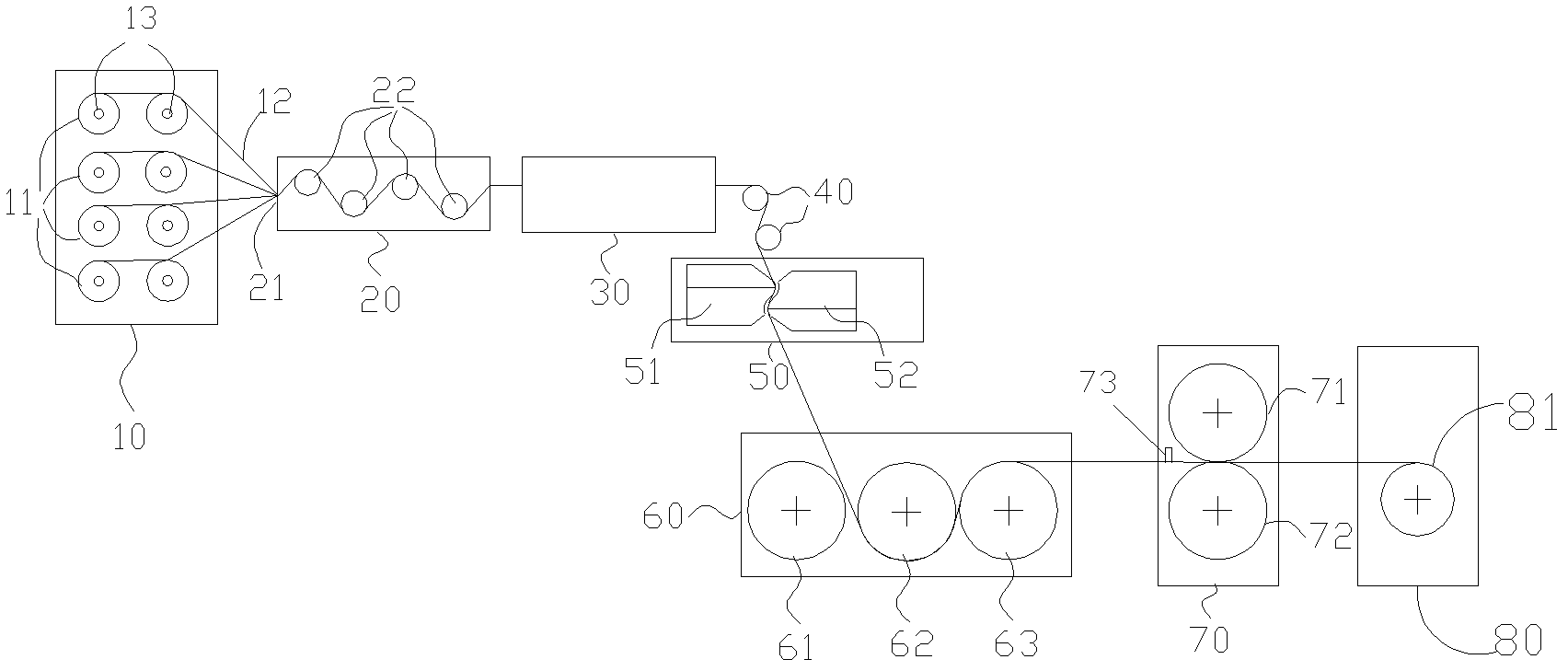

[0050] The continuous glass fiber roll 11 is installed on the spindle 13 of the creel 10, and the fiber is pulled through the guide wire hole on the creel, and the exported fiber is passed through the thread discharge port 21 of the tension adjustment device, so that the fibers are arranged in parallel and evenly, and the continuous fiber wears The tension adjusting roller 22 of the tension...

Embodiment 2

[0055] 40% nylon 6 resin, 0.7% maleic anhydride-acrylic acid copolymer compatibilizer, 0.3% N, N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl )propionyl)hexamethylenediamine (antioxidant 1098), 0.3% tris(2,4-di-tert-butylphenyl) phosphite (antioxidant 168), 0.5% ethylene difatty acid lubricant, 40% ferrite wave-absorbing material is mixed evenly at room temperature in a high-speed mixer for 80 seconds at a low speed, and then granulated in a twin-screw extruder. The processing temperature is 210-280°C, and the frequency of the extruder is 20Hz. Wave-absorbing nylon 6 masterbatch.

[0056] The continuous carbon fiber roll is installed on the spindle 13, and the fiber is pulled through the thread guide hole on the creel, and the exported fiber is passed through the thread outlet 21 of the tension adjustment device, so that the fibers are arranged in parallel and evenly, and the continuous fiber passes through the tension adjustment roller 22, A certain tension is applied to the f...

Embodiment 3

[0061] 50% polybutylene terephthalate (PBT) resin, 3% acrylate grafted polypropylene compatibilizer, 0.4% tetrakis[3-(3,5-di-tert-butyl-4- Hydroxyphenyl)propionic acid]pentapentaerythritol ester (antioxidant 1010), 0.4% tris(2,4-di-tert-butylphenyl) phosphite (antioxidant 168), 0.7% stearin The butyl ester lubricant and 10% cobalt oxide wave-absorbing material are mixed uniformly in a high-speed mixer at room temperature and at a low speed for 75 seconds, and then granulated in a twin-screw extruder. The processing temperature is 220-300°C, and the extruder frequency At 30Hz, it is made into a wave-absorbing polybutylene terephthalate masterbatch.

[0062] The continuous boron fiber roll is installed on the spindle 13, and the fiber is pulled through the thread guide hole on the creel, and the exported fiber is passed through the thread outlet 21 of the tension adjustment device, so that the fibers are arranged in parallel and evenly, and the continuous fiber passes through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com