A method of printing uv ink on furniture board

A technology for furniture and boards, applied in the direction of copying/marking, printing, coating, etc., can solve the problems of heavy metals in furniture exceeding the standard, UV ink patterns are easy to fall off, etc., and achieve the effect of firm patterns, good pattern expressiveness, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Follow the steps below to print UV ink on the melamine board:

[0042] (1) Mix resin, curing agent and solvent according to the weight ratio of 1:0.5:0.8 to obtain bridging agent;

[0043] (2) Put the bridging agent into the spraying equipment for spraying, so that the bridging agent is sprayed onto the clean and dried melamine board;

[0044] (3) Dry the melamine board sprayed with bridging agent at room temperature for 60 minutes;

[0045] (4) Place the dried melamine board in a UV inkjet printer for ink spraying to obtain a sample board.

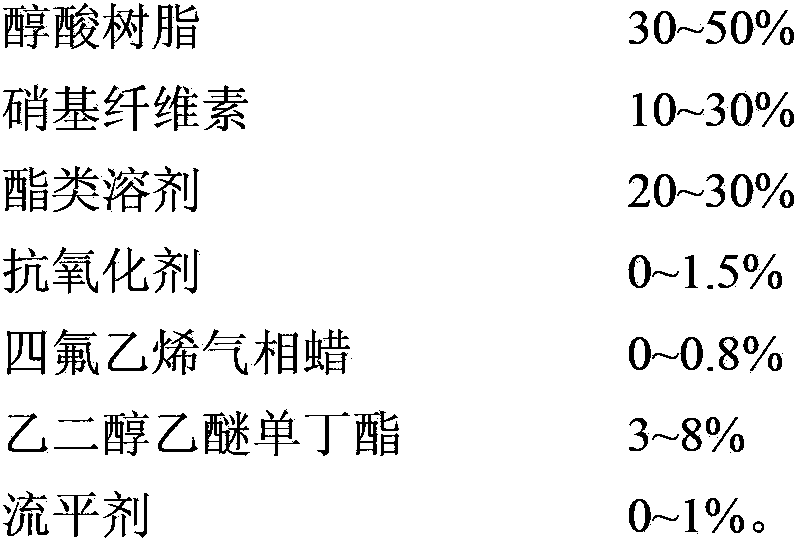

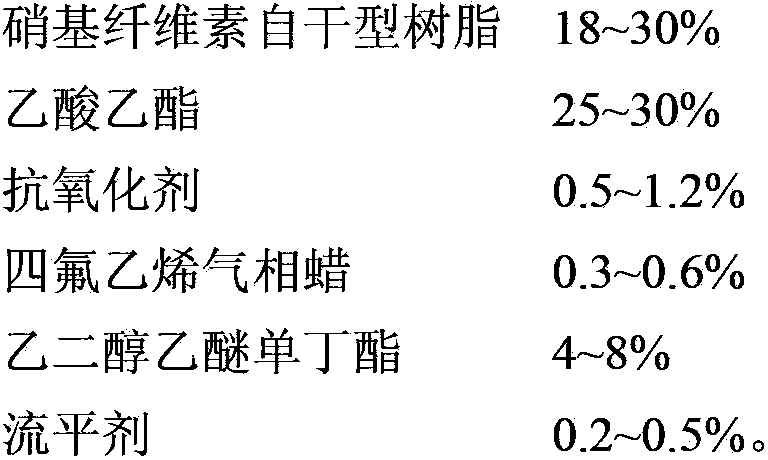

[0046] Wherein the resin comprises the following components by weight percentage: 45% cottonseed oil modified alkyd resin, 20% nitrocellulose, 28% ethyl acetate, 0.5% tetrafluoroethylene gas phase wax, 6.5% ethylene glycol ethyl ether monobutyl ester ; Curing agent contains 50% low free TDI curing agent raw material, 50% ethyl acetate; butyl ester.

[0047] 2. Formaldehyde content test

[0048] According to GB / T18584-2004, ...

Embodiment 2

[0060] 1. Follow the steps below to print UV ink on the melamine board:

[0061] (1) Mix the resin, curing agent and solvent according to the weight ratio of 1.5:0.25:0.5 to obtain the bridging agent;

[0062] (2) Put the bridging agent into the spraying equipment for spraying, so that the bridging agent is sprayed onto the clean and dried melamine board;

[0063] (3) Dry the melamine board sprayed with bridging agent at room temperature for 60 minutes;

[0064] (4) Place the dried melamine board in a UV inkjet printer for ink spraying to obtain samples.

[0065] Wherein the resin comprises the following components by weight percentage: 40% soybean oil modified alkyd resin, 29.4% nitrocellulose, 25% ethyl acetate, 1% paraldehyde, 0.6% tetrafluoroethylene gas phase wax, 4% Ethylene glycol ethyl ether monobutyl ester; curing agent contains 70% low free TDI curing agent raw material, 30% ethyl acetate; solvent includes the following components in weight percentage: 85% ethyl ac...

Embodiment 3

[0079] 1. Follow the steps below to print UV ink on the melamine board:

[0080] (1) Mix the resin, curing agent and solvent in a weight ratio of 1.5:0.75:0.5 to obtain a bridging agent;

[0081] (2) Put the bridging agent into the spraying equipment for spraying, so that the bridging agent is sprayed onto the clean and dried melamine board;

[0082] (3) Dry the melamine board sprayed with bridging agent at room temperature for 60 minutes;

[0083] (4) Place the dried melamine board in a UV inkjet printer for ink spraying to obtain samples.

[0084] Wherein the resin comprises the following components by weight percentage: 30% soybean oil modified alkyd resin, 30% nitrocellulose, 30% ethyl acetate, 1% tetrafluoroethylene gas phase wax, 8% ethylene glycol ethyl ether monobutyl ester and 1% polyether modified polydimethylsiloxane; the curing agent contains 60% low free TDI curing agent raw material, 40% ethyl acetate; the solvent includes the following components in weight per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com