Boiler feedwater treatment method and treatment system related to reuse of reclaimed water

A water treatment system and technology for water treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problem of low pretreatment system efficiency, ion exchange regeneration Frequent problems, serious environmental pollution, etc., to achieve the effects of easy automatic control, small footprint, and high impurity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

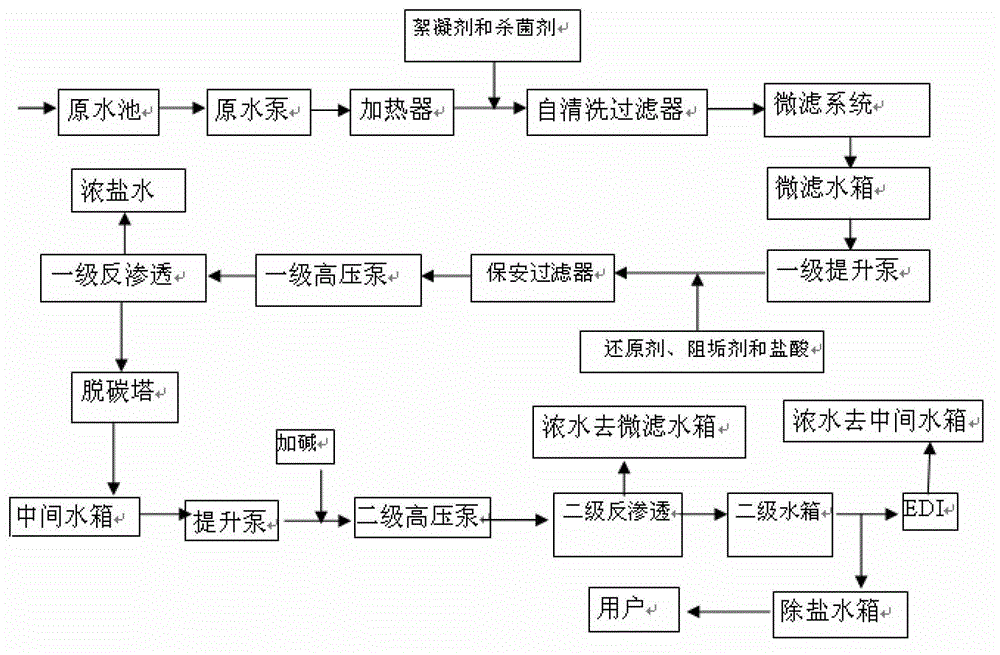

[0122] Raw water of different water quality (30% reclaimed water by weight and 70% new industrial water by weight, the specific water quality indicators are shown in Table 3 below) first enters two 1000m 3 The underground pool serves as a system buffer and a regulating pool for different water qualities. Then it is transported to the membrane treatment workshop through three (two-purpose and one standby) raw water pumps, and then enters the microfiltration system after passing through the raw water heater, the dosing mixer, and the self-cleaning filter.

[0123] The water quality parameter of table 3 embodiment raw water

[0124]

[0125] Raw water heater: Since the temperature of the raw water source will be lower than 10°C in winter, the best working temperature of reverse osmosis is 25±3°C. For this reason, a raw water heater is set up to save water resources to the greatest extent while exchanging heat. The specific parameters of the heater are shown in Table 4 below. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com