Sewage treatment system and method for natural gas purifying factory in H2S-containing gas field

A sewage treatment method and sewage pretreatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, gaseous effluent wastewater treatment, etc., can solve the problems of difficult biochemical treatment, increased pollution load, and frequent regeneration and other issues, to achieve the effect of reducing maintenance and management workload, reducing the toxicity of harmful substances, and reducing the concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

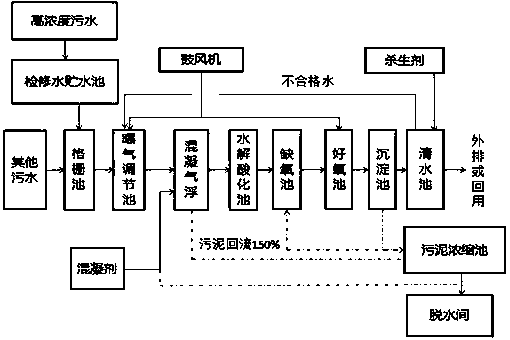

[0031] a H 2 The sewage treatment system of the S gas field natural gas purification plant, such as figure 1 As shown, it includes: maintenance water storage tank, grid tank, aeration adjustment tank, coagulation air flotation device, hydrolysis acidification tank, anoxic tank, aerobic tank, sedimentation tank and clean water tank connected in sequence; the clean water tank is also passed through The pipeline is connected to the aeration regulating tank, which is used to introduce unqualified water into the aeration regulating tank; the blower aerates the aeration regulating tank and the aerobic tank; The sedimentation tank is connected to collect sludge for thickening; the sludge thickening tank is further connected to the dehydration room. The present invention is also provided with sewage recycling equipment for reusing the treated sewage.

[0032] The present invention also provides a 2 The sewage treatment method of S gas field natural gas purification plant comprises ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com