Preparation method of mineral wool vacuum insulation panel core material

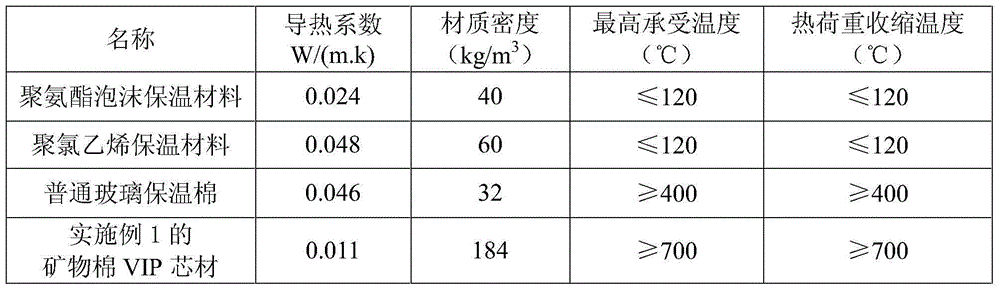

A technology of vacuum insulation panels and mineral wool, which is applied in the field of preparation of core materials of mineral wool vacuum insulation panels, can solve the problems that thermal conductivity does not fully meet the requirements of high-performance thermal insulation and high production costs, and achieves good thermal insulation effects, The effect of product flatness and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of the novel mineral wool VIP core material of the present embodiment may further comprise the steps:

[0022] 1) Dispersion pulping: add rock wool fibers to the deflaking machine, then add sulfuric acid and water to disperse, disperse the rock wool fibers to a diameter of less than 1.5 μm; then send the dispersed rock wool fibers into the storage stirring tank, and then add sulfuric acid and clear water adjusted to a pH value of 4.0 and a slurry with a mass concentration of 3.5%;

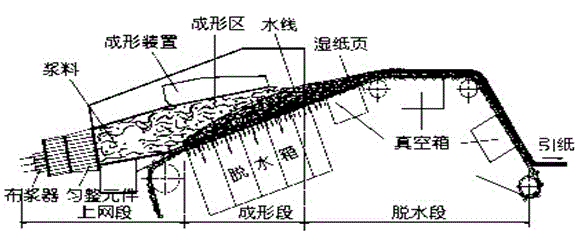

[0023] 2) Forming: Dilute the slurry obtained in step 1) to a mass concentration of 0.3%, and then perform slag removal; then transport the slurry to an inclined wire former for wet forming, dehydration forming in six stages, the first Section dehydration capacity is 8m 3 / (min.m), the dehydration capacity of the second stage is 8m 3 / (min.m), the dehydration capacity of the third stage is 8m 3 / (min.m), the dehydration capacity of the fourth stage is 7m 3 / (min.m)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com