Regeneration technology of recovered methylamine solution and device thereof

A methylamine, solution technology, used in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., to achieve the effect of reducing tower height, operating flexibility, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

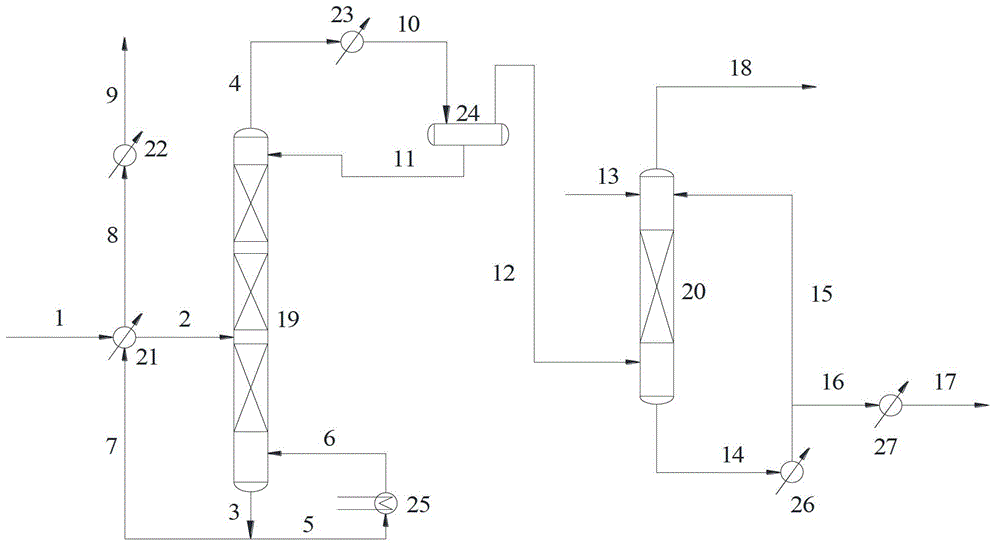

[0021] like figure 1 Shown, the 10% methylamine aqueous solution that reclaims contains impurities such as acetone, butanol, tetrahydrofuran, and raw material methylamine solution 1 is in separation tower bottom waste material-raw material heat exchanger 21 after heat exchange with the high-temperature waste material from separation tower tower kettle, reclaims The methylamine solution 2 enters the separation tower 19 from the lower part of the separation tower. Separation tower adopts structured packing tower, and operating pressure is 0.2Mpa, and tower top temperature is 10 ℃, and theoretical plate is 20, and feeding plate is the 10th plate, and reflux ratio is 0.2. A part of the high-temperature waste material 3 in the tower kettle is used as waste material primary heat exchange feed 7, and is input into the waste material-raw material heat exchanger 21 at the bottom of the separation tower to preheat the raw material, and the waste material primary heat exchange discharge ...

Embodiment 2

[0023] like figure 1Shown, the 35% methylamine aqueous solution that reclaims contains the impurity such as dimethylamine, trimethylamine, raw material methylamine solution 1 is in separation tower bottom waste material-raw material heat exchanger 21 after heat exchange with the high-temperature waste material from separation tower still, reclaims The methylamine solution 2 enters the separation tower 19 from the lower part of the separation tower. Separation tower adopts structured packing tower, and operating pressure is 0.5Mpa, and tower top temperature is 40 ℃, and theoretical plate is 50, and feeding plate is the 35th plate, and reflux ratio is 1.5. A part of the high-temperature waste material 3 in the tower kettle is used as waste material primary heat exchange feed 7, and is input into the waste material-raw material heat exchanger 21 at the bottom of the separation tower to preheat the raw material, and the waste material primary heat exchange discharge material 8 pas...

Embodiment 3

[0025] like figure 1 Shown, the 90% methylamine aqueous solution that reclaims contains dimethylamine, trimethylamine, tetrahydrofuran (THF), acetone, impurities such as methyl alcohol, and raw material methylamine solution 1 is in separation tower bottom waste material-raw material heat exchanger 21 and comes from separation tower tower still high temperature After waste heat exchange, the recovered methylamine solution 2 enters the separation tower 19 from the middle and lower part of the separation tower. Separation tower adopts valve tower, and operating pressure is 1Mpa, and tower top temperature is 70 ℃, and theoretical plate is 60, and feeding plate is the 50th plate, and reflux ratio is 2. A part of the high-temperature waste material 3 in the tower kettle is used as waste material primary heat exchange feed 7, and is input into the waste material-raw material heat exchanger 21 at the bottom of the separation tower to preheat the raw material, and the waste material pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com