Synthetic method of photoinitiator dual (2,4,6-trimethylbenzene formyl group) phenyl phosphine oxide

A technology of trimethylbenzoyl and photoinitiator, applied in the field of chemical industry, can solve problems such as unsafe yield, and achieve the effects of low comprehensive cost, high safety, and not easy to fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

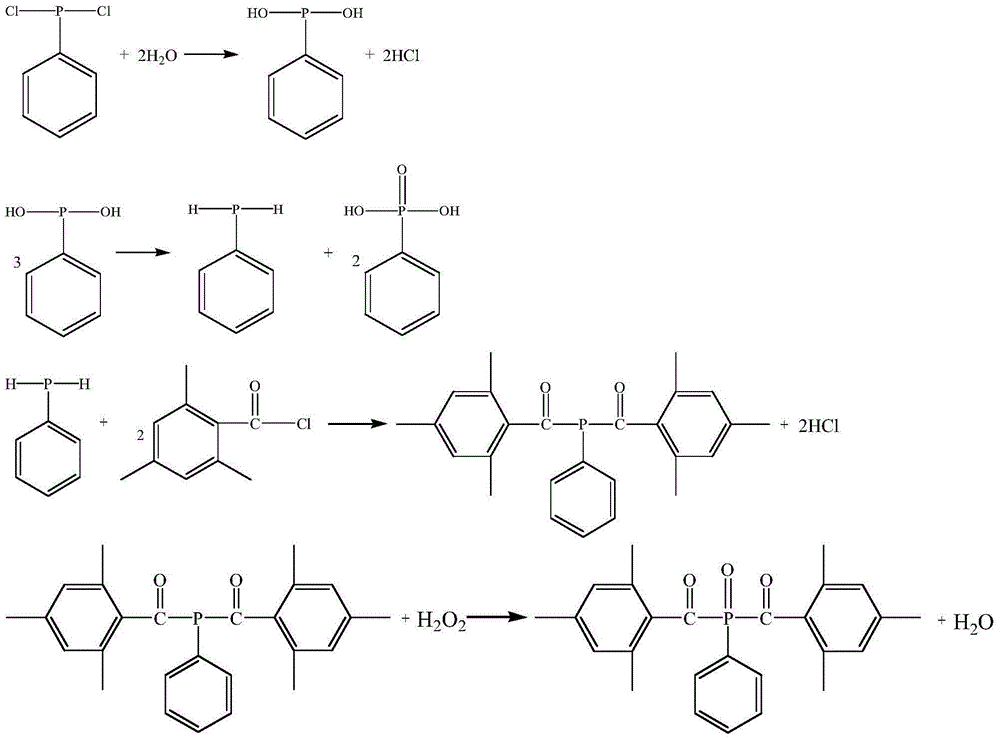

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Add 17.9 grams of phenylphosphine dichloride and 100 mL of toluene into a 250 mL reactor as a solvent, pass through nitrogen to remove oxygen, and add 4.0 grams of pure water dropwise under nitrogen protection to control the temperature within 0°C. Incubate at -10°C for 2 hours to generate phenylphosphine and by-product phenylphosphonic acid.

[0022] The second step: filter, the filter cake is washed with an appropriate amount of toluene, and the obtained solid is the by-product phenylphosphonic acid; a small amount of anhydrous calcium chloride is added to the filtrate, and the calcium chloride is removed by filtration, and the filtrate is transferred to the reactor, and the temperature is controlled at 60 Add 12.2 grams of 2,4,6-trimethylbenzoyl chloride dropwise at ℃, keep warm at 60℃ for 2 hours after the addition, adjust the reaction solution to neutral with 10% sodium hydroxide, separate the organic layer to obtain the intermediate product Bis(2,4,6-trime...

Embodiment 2

[0026] Step 1: Add 17.9 grams of phenylphosphine dichloride and 100 mL of chloroform into a 250 mL reactor as a solvent, pass through nitrogen to remove oxygen, control the temperature within 0 ° C under the protection of nitrogen, add 3.8 grams of pure water dropwise, after adding 0-10 ° C for 2 hours to generate phenylphosphine and by-product phenylphosphonic acid.

[0027] The second step: filtering, the filter cake is washed with an appropriate amount of chloroform, and the obtained solid is the by-product phenylphosphonic acid. Add a small amount of anhydrous calcium chloride to the filtrate, remove the calcium chloride by filtration, transfer the filtrate to the reactor, add 12.2 grams of 2,4,6-trimethylbenzoyl chloride dropwise at a controlled temperature of 60°C, and add it at 60 The temperature was kept at ℃ for 2 hours, and after the heat preservation, the reaction solution was adjusted to neutrality with 10% sodium hydroxide, and the organic layer was separated to o...

Embodiment 3

[0032] Step 1: Add 17.9 grams of phenylphosphine dichloride to a 250 mL reactor, then add 100 mL as a solvent, pass through nitrogen to remove oxygen, control the temperature within 0°C under the protection of nitrogen, add 3.8 grams of pure water dropwise, after adding Incubate at 80°C for 2 hours.

[0033] The second step: filtering, the filter cake is washed with an appropriate amount of chloroform, and the obtained solid is the by-product phenylphosphonic acid. Add a small amount of anhydrous calcium chloride to the filtrate, remove the calcium chloride by filtration, transfer the filtrate to the reactor, add 12.2 grams of 2,4,6-trimethylbenzoyl chloride dropwise at a controlled temperature of 60°C, and add it at 60 The temperature was kept at ℃ for 2 hours, and after the heat preservation, the reaction solution was adjusted to neutrality with 10% sodium hydroxide, and the organic layer was separated to obtain the intermediate product bis(2,4,6-trimethylbenzoyl)phenylphosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com