Intelligent thermo-sensitive glycosyl hydrogel with dumbbell structure and preparation method of hydrogel

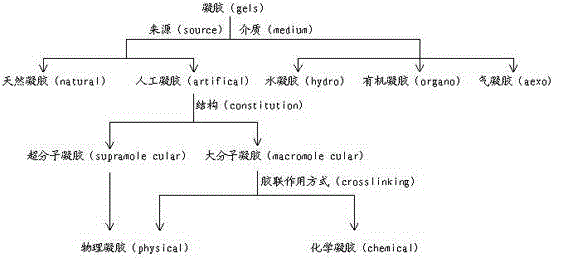

A thermosensitive, hydrogel technology, applied in the field of dumbbell structure thermosensitive sugar-based smart hydrogel and its preparation, can solve the problems of low stimulus response sensitivity and poor stability, and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Synthesis of allyl diacetone glucose: In a 250 mL four-neck flask equipped with a thermometer reflux condenser, add 150 mL of dry anhydrous acetone and 9.0 g (0.05 mol) of crushed and dried glucose, add catalyst anhydrous FeCl 3 (1.7g, 0.01mol). Reflux reaction under ultrasonic conditions for 2h. Then dilute Na 2 CO 3 Solution 300 ml, CHCl 3 Extract three times (50 ml×3), combine the organic phases and wash with saturated brine (50 ml×3), wash with anhydrous Na 2 SO 4 Dry, filter and distill under reduced pressure to obtain a crude product with a yield of 75.8%. Recrystallize with cyclohexane to obtain white crystalline diacetone glucose DAG. In a 250mL dry and clean three-necked flask, add DAG (10 g, 0.04mol) and 80mL dry tetrahydrofuran and stir to dissolve. Under nitrogen protection, add 60% sodium hydride (2.4g, 0.052 mol), and then The reaction was stirred for 1 h, and allyl bromide (5.45 g, 0.045 mol) was slowly added dropwise. After the addition was complet...

Embodiment 2

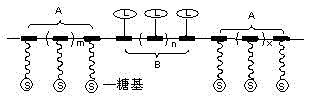

[0033] The difference from Example 1 is: in a 250 mL four-necked flask equipped with a thermometer, add 100 ml of tetrahydrofuran, then add 5.0 g of 3-allyl diacetone glucose and 0.2 g of dimethylbenzyl dithiobenzoate g, under the protection of nitrogen, add 0.05 g of initiator azobisisobutyronitrile AIBN, react for 2 hours in a water bath at 70 ° C, and use TLC to detect that the polymerization of the allyl sugar-based monomer is complete; then add the comonomer N- Propyl acrylamide 10.0 g was continued to polymerize at 70°C for 5 h, and the reaction was detected by TLC until the monomer basically disappeared; 5.0 g of allyl diacetone glucose dissolved in 50 mL of tetrahydrofuran was added by steel needle transfer method, and the polymerization was continued for 5 h. Add 2 mol / L hydrochloric acid to hydrolyze the deprotected acetone, hydrolyze for 2 hours, precipitate with methanol, and dry to obtain 15.3 g of “glycosyl-N-propylacrylamide-glycosyl” dumbbell structure glycosyl ...

Embodiment 3

[0035] The difference from Example 1 is: in a 250 mL four-necked flask equipped with a thermometer, add 100 ml of tetrahydrofuran, then add 5.0 g of 3-allyl diacetone glucose and 0.2 g of dimethylbenzyl dithiobenzoate g, under the protection of nitrogen, add 0.05 g of initiator azobisisobutyronitrile AIBN, react for 2 hours in a water bath at 70 ° C, and use TLC to detect that the polymerization of allyl sugar-based monomers is complete; then add comonomer N, 10.0 g of N-diethylacrylamide, continue to polymerize at 70 ° C for 5 h, TLC detects the reaction until the monomer basically disappears; add 5.0 g of allyl diacetone glucose dissolved in 50 mL of tetrahydrofuran by steel needle transfer method, and continue to polymerize 5h. Add 2 mol / L hydrochloric acid to hydrolyze the deprotected acetone, hydrolyze for 2 hours, precipitate with methanol, and dry to obtain 16.4 g of “glycosyl-N,N-diethylacrylamide-glycosyl” dumbbell structure glycosyl hydrogel.

[0036] The structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com