Food waste treating method

The technology of a kitchen waste and a treatment method, which is applied in the field of kitchen waste treatment, can solve the problems of increasing the difficulty of urban domestic waste treatment of kitchen waste, easily polluting equipment and the environment, rot and deterioration, etc. Covering area and suppressing the effect of breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

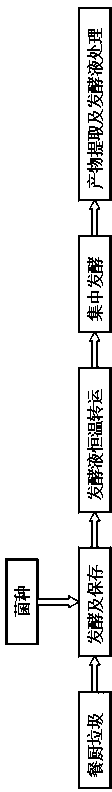

[0044] like figure 1 Shown is the flow chart of the kitchen waste treatment method of the present invention, specifically comprising the following steps:

[0045] Step 1, on-site fermentation: Put the freshly produced food waste into the on-site food waste fermentation device installed at the food waste production site, and ferment under the set fermentation conditions according to the different fermentation strains;

[0046] Step 2, transfer: After the food waste is fermented in the on-site fermentation device for the set time, the fermentation liquid is transferred to the fermentation liquid constant temperature transport vehicle, and the fermentation conditions in step 1 are kept unchanged. Continue to ferment in the fermentation container; transport the fermented liquid to the centralized treatment plant through the fermented liquid constant temperature transport vehicle;

[0047] Step 3, concentrated fermentation: After the food waste fermentation liquid is transferred to ...

Embodiment 2

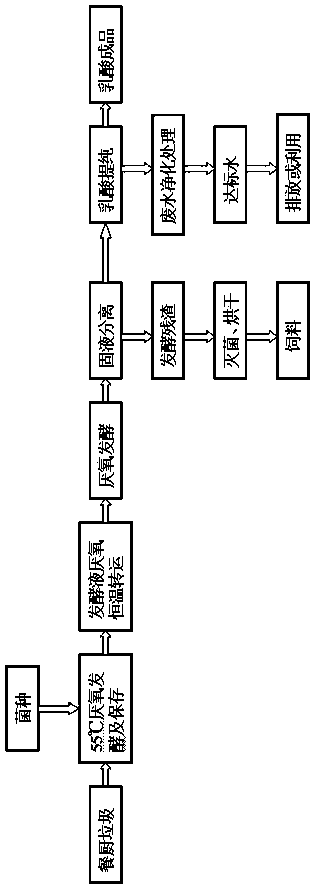

[0062] The food waste treatment process in this embodiment is as follows image 3 As shown, its basic processing flow is the same as the four steps described in embodiment 1, but the processing conditions of each step are slightly different, specifically:

[0063] In step 1, no strains are added, the food waste is not sterilized, and the lactic acid bacteria naturally present in the food waste are used for natural anaerobic fermentation at a fermentation temperature of 37-38°C. The pH value of the fermentation broth was not adjusted during the fermentation process.

[0064] In step 1, the volume of the fermenter in the on-site fermentation treatment device is 150-500 liters, the average volume is 300 liters, and the number is 300.

[0065] In step 2, the food waste constant temperature transport vehicle has a carrying capacity of 4 tons, and each vehicle can transfer the fermentation liquid produced by 13 food waste generation points every round trip.

[0066] The remaining ...

Embodiment 3

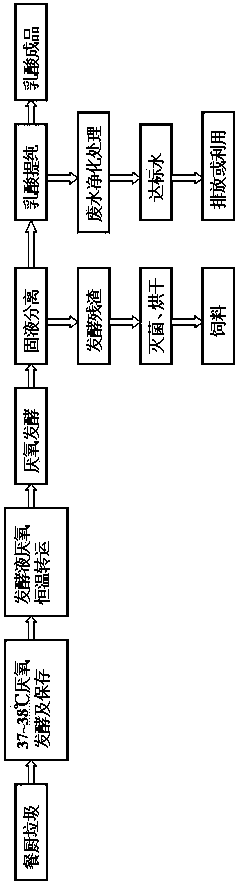

[0074] The food waste treatment process in this embodiment is as follows Figure 4 As shown, its basic processing flow is the same as the four steps described in embodiment 1, but the processing conditions of each step are slightly different, specifically:

[0075] In step 1, in step 1, during the first fermentation, put into the fermenter tank the fermented Bacillus L-lactate-producing Bacillus fermentation seed liquid accounting for 1 / 30 of the volume of the fermenter. Additional fermented seed liquid was added, but the remaining 1 / 30 volume of the remaining fermented liquid was used as the seed liquid after each suction of the fermented liquid. Aerobic fermentation, fermentation temperature 55 ℃. The kitchen waste is not sterilized, and the pH value of the fermentation liquid is not adjusted during the fermentation process.

[0076] In step 1, the volume of the fermentation tanks in the on-site fermentation treatment device is 150-500 liters, the average volume is 300 lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com