Electrochemical deoxidization method for refining titanium and titanium alloy solution

A titanium alloy, electrochemical technology, applied in the field of electrochemical deoxidation, can solve problems affecting the performance of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0013] Now the specific embodiment of the present invention is described as follows

Embodiment

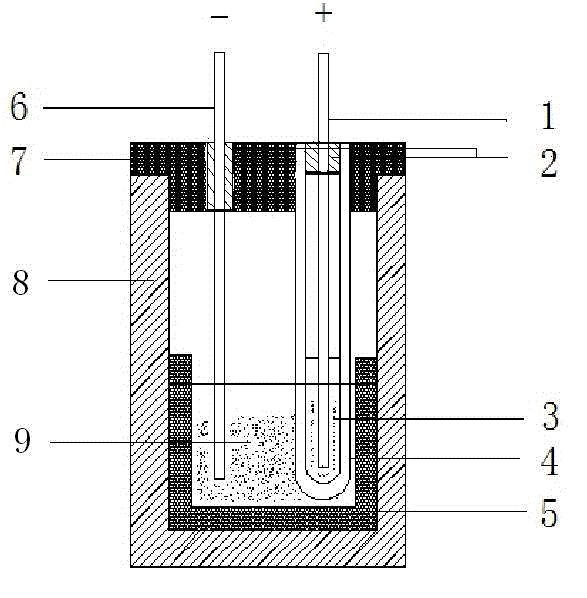

[0015] will be like figure 1 The electrochemical deoxidation device shown is placed in a conventional general-purpose vacuum high-temperature furnace, and the temperature is raised slowly while the vacuum is continuously pumped. When the temperature rises to 1000°C, the vacuum pumping is stopped, and the furnace is backfilled with high-purity argon to 10 -2 Pa, and then continue to heat up to 1400 ° C. Then, an adjustable DC power supply was used to load a constant DC voltage of 2.8V between the cathode and the anode, electrolyze at a voltage of 2.8V, and record the loop current. As the electrolysis proceeds, the electrolysis current gradually decreases. When the electrolysis reaches 3.5 hours, the current suddenly decreases to almost 0, and the titanium alloy sample is completed. The oxygen content in the electrochemical deoxidation process of the titanium alloy is very low, and there is no longer O 2- Migration generates electric current. After electrolysis, cool to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com