Preparation process of nickel-coated silicon carbide powder for surface enhancement of impression of hot forging mold

A silicon carbide powder and surface strengthening technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of difficult industrial scale production, easy decomposition and application of plating solution, difficult reaction control, etc. The effect of purchasing, the surface of the cavity surface is dense, and the coating layer is dense and uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

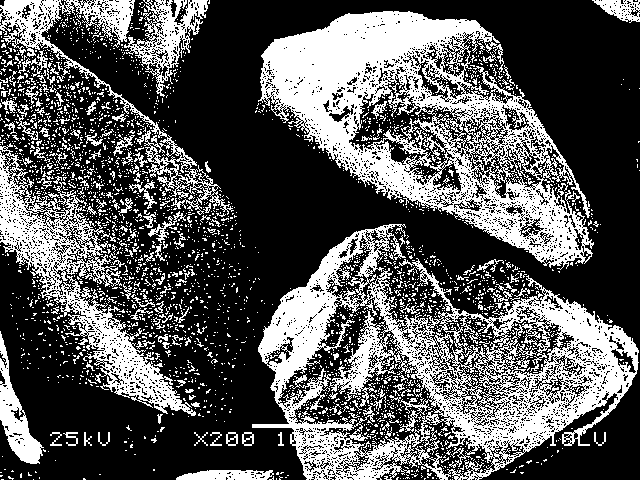

[0030] The treatment process of the pretreated silicon carbide powder is:

[0031] 1) First use 6% NaOH solution to ultrasonically degrease the silicon carbide powder, then neutralize it with dilute hydrochloric acid, and then ultrasonically clean it with deionized water;

[0032] 2) Then use 5wt% HF solution to etch for 5min to roughen, so that the particle surface of silicon carbide powder is rough, so as to improve the bonding force between the coating and the substrate. After roughening, rinse with deionized water and dry at 80°C;

[0033] 3) For sensitization treatment, use 10% SnCl 2 The hydrochloric acid solution impregnated the dried silicon carbide powder for 5 minutes, and the sensitization solution was recovered after vacuum filtration, and the silicon carbide powder was washed with water to form a gel layer on the surface, and divalent tin ions were adsorbed in the gel layer. reductive;

[0034] 4) After the sensitization treatment, the silicon carbide powder is...

Embodiment 2

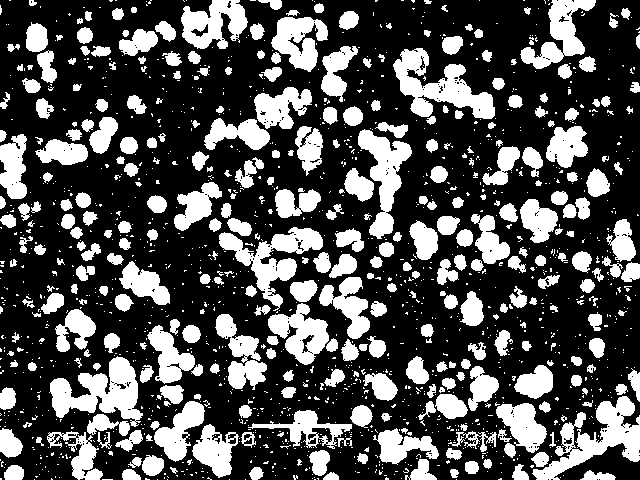

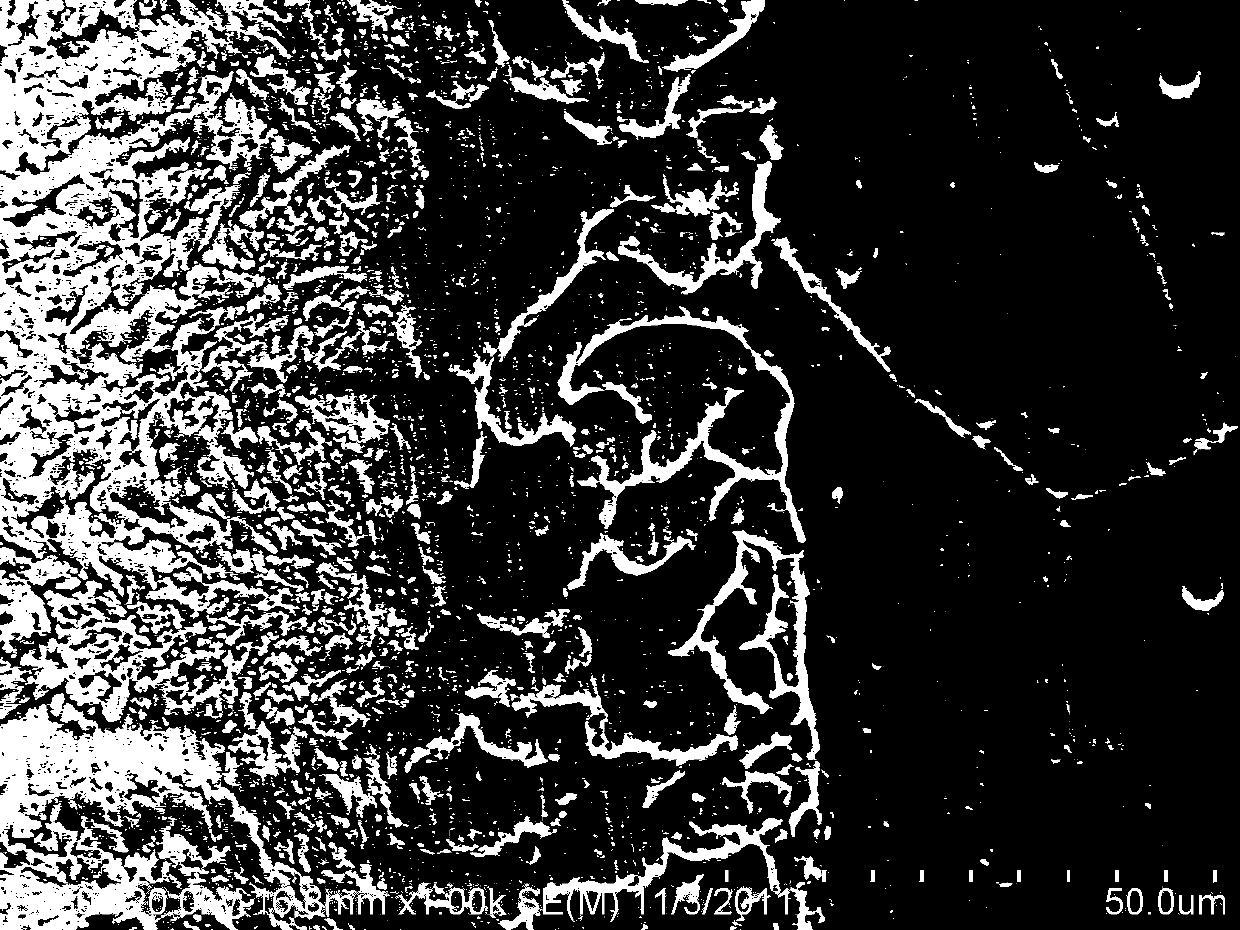

[0040] Adjust the pH value of the filtered plating solution in Example 1 to 4.6, set the plating temperature to 90°C, and perform plating with the silicon carbide powder loading ratio after pretreatment at 20g / L. After 55 minutes, the plating solution appears A large number of bubbles and become turbid, the phenomenon is the same as in Example 1, and the obtained coating layer is also dense and uniform, and the plating can still be carried out normally until the third plating is repeated, and there is no reaction in the fourth plating. After adding 10g / L of nickel sulfate as the main salt and 10g / L of sodium hypophosphite as the reducing agent, the plating solution returns to the normal plating state.

[0041]

Embodiment 4

[0045] The pH of the plating solution filtered in Example 3 is adjusted to pH4.8, the loading ratio is 25g / L, the temperature is set at 90°C, and the plating is carried out again. After 30 minutes, the same phenomenon as in Example 3 is observed. The coating quality is poor and the plating solution is unstable. After continuing to filter, carry out plating for the third time and there is no reaction, and the plating solution is invalid. It shows that the amount of stabilizer added is unreasonable, the stability of the plating solution is poor, and it is easy to fail quickly.

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com