Method for producing phosphate by purifying phosphorus mud to prepare acid

A phosphate and phosphorus sludge technology, applied in the direction of phosphate, phosphoric acid, phosphorus oxyacid, etc., can solve the problems of low phosphorus recovery rate, environmental pollution, poor quality of phosphate, etc., and achieve high recovery rate and low impurity content , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

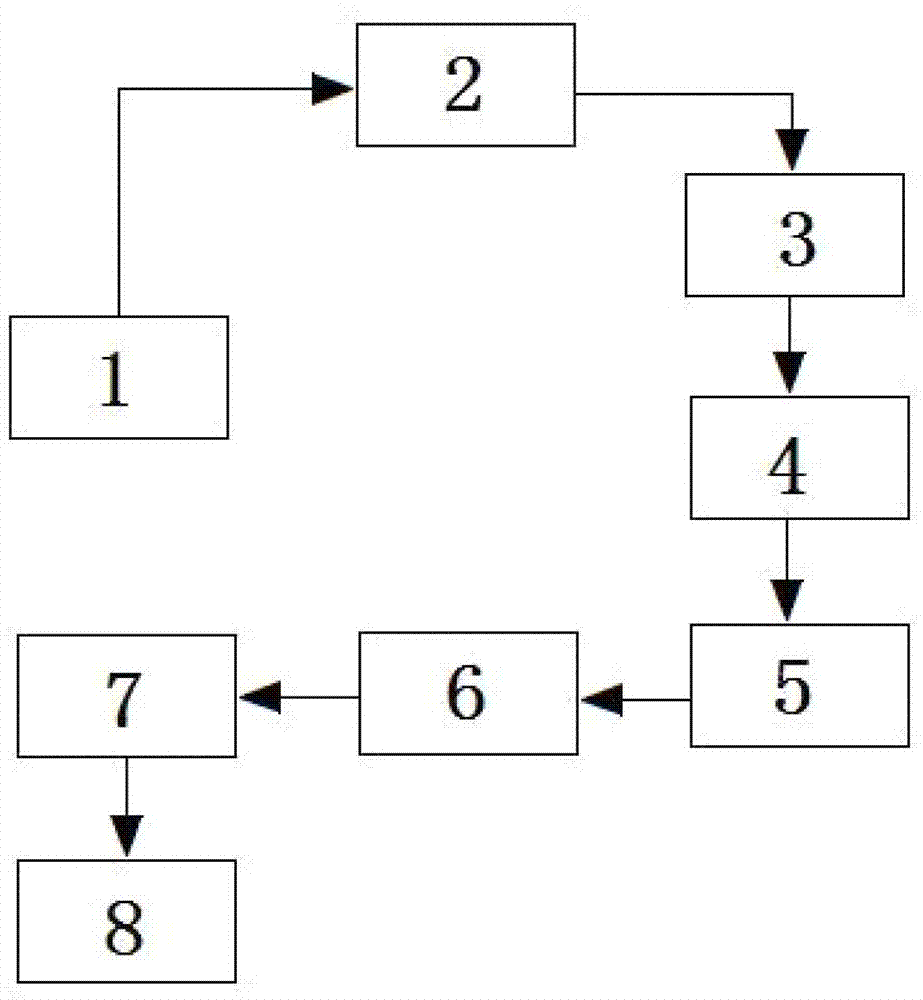

Method used

Image

Examples

Embodiment 1

[0030] The arsenic content of phosphoric acid with a mass concentration of 70% is 0.0066% after analysis, and the arsenic content in the produced sodium hexametaphosphate is 0.0083%, which cannot meet the requirements of qualified products. Add 5 kg of phosphorus pentasulfide to the above 10 tons of phosphoric acid, keep the temperature at 55°C and stir for 40 minutes to press filter, the purified acid after the press filter is used for the production of sodium hexametaphosphate, and the arsenic content in the produced sodium hexametaphosphate is 0.0002 %, fully meet the requirements of qualified products.

Embodiment 2

[0032] The arsenic content of phosphoric acid with a mass concentration of 65% is 0.0053% after analysis. The arsenic content in the potassium dihydrogen phosphate produced with this acid is 0.0062%, and the product quality is unqualified. Add 3.4 kg of phosphorus pentasulfide to the 8 tons of phosphoric acid produced by burning phosphorus mud, keep the temperature at 65°C and stir for 45 minutes to press filter. The purified acid after the press filter is used for the production of potassium dihydrogen phosphate. The content is 0.0001%, and the product quality is qualified.

Embodiment 3

[0034] The arsenic content of phosphoric acid with a mass concentration of 65% is 0.0053% after analysis. The arsenic content in the potassium dihydrogen phosphate produced with this acid is 0.0062%, and the product quality is unqualified. Add 3.4 kg of phosphorus pentasulfide to the 8 tons of phosphoric acid produced by burning phosphorus mud, keep the temperature at 80°C and stir for 50 minutes to press filter. The purified acid after the press filter is used to produce potassium dihydrogen phosphate. The content is 0.0003%, and the product quality is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com