Keratin-peptide-modified polyethylene glycol hydrogel, and preparation method and application thereof

A keratin peptide, polyethylene glycol technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, biochemical instruments, etc., can solve the problem of heavy environmental burden, high cost of synthetic peptides, and reproduction of natural biological materials. It has the effect of promoting cell adhesion and growth, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

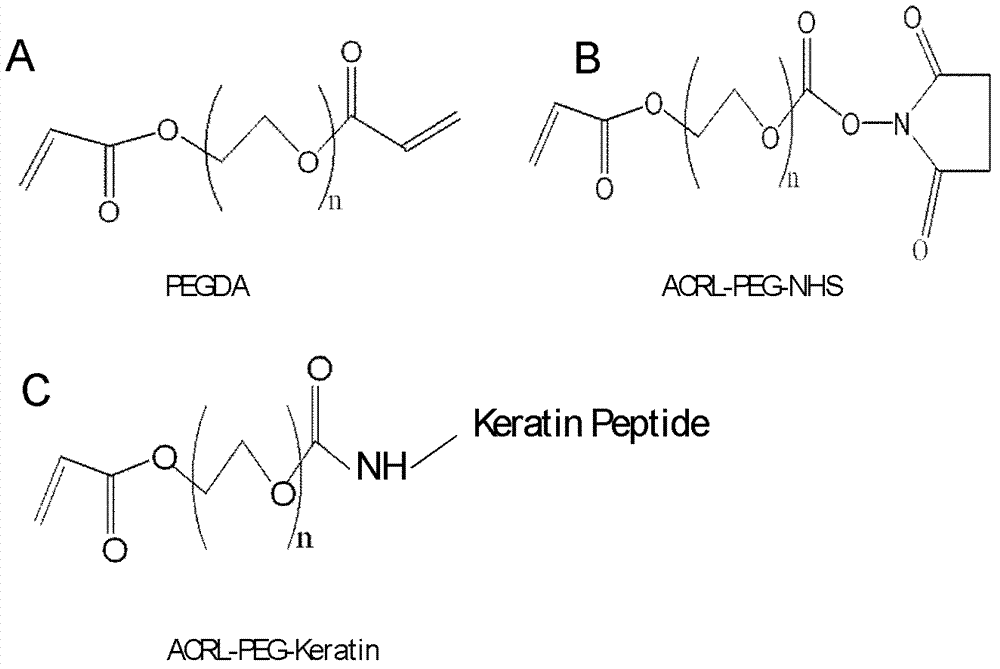

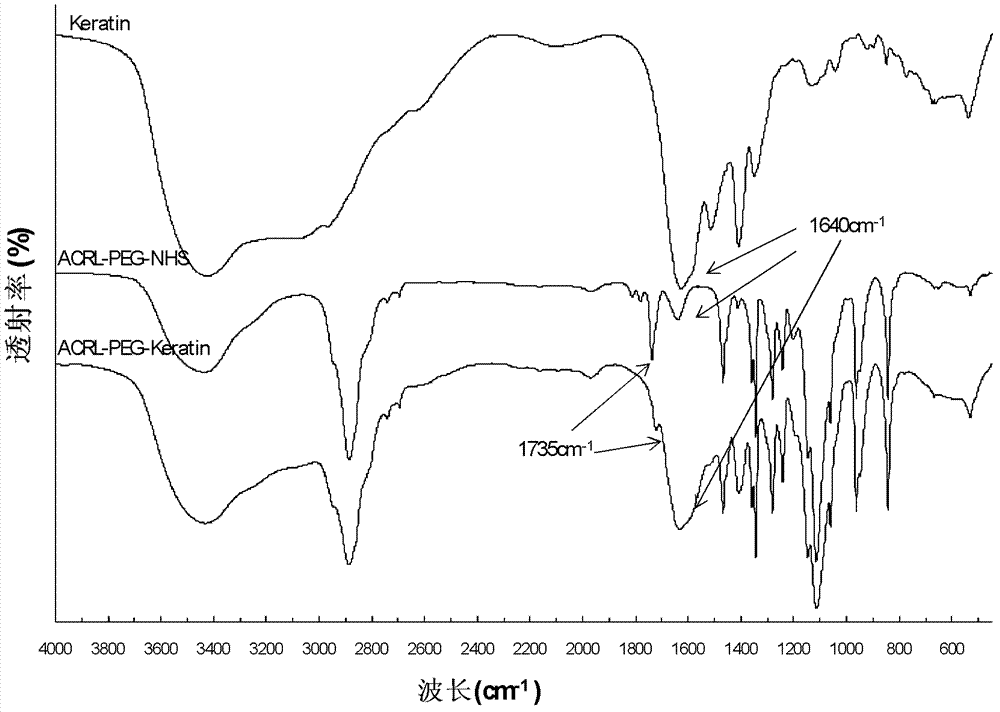

[0059] Example 1 - Preparation of Vinyl Pegylated Keratin Peptides

[0060] Extraction of Keratin Peptides:

[0061] Get 60 grams of washed and dried wool and add it to 400ml of 4mol / L hydrochloric acid solution. React for 24 hours in a constant temperature water bath at 95°C. The obtained wool hydrolyzate is filtered, and sodium hydroxide solution is dropped in the obtained filtrate to adjust the keratin peptide solution to neutrality while stirring, and then spray-dried to form keratin peptide powder.

[0062] Preparation of vinyl PEGylated keratin peptides:

[0063]The keratin peptide powder was dissolved in 100 mM sodium bicarbonate solution until saturated, and the pH value of the resulting solution was adjusted to 8.2 by dropwise adding 1 M sodium hydroxide solution to form a keratin peptide solution. Filter through a filter with a pore size of 0.2 microns. Add 100 mg / ml of Acrl-PEG-NHS (MW3400) powder to the pH-adjusted keratin peptide solution, and react at room te...

Embodiment 2

[0064] Example 2 - Preparation of Vinyl Pegylated Keratin Peptides

[0065] Extraction of Keratin Peptides:

[0066] Get 50 grams of washed and dried human hair, and add it in 400ml hydrochloric acid solution of 3mol / L. React for 12 hours in a constant temperature water bath at 95°C. The obtained human hair hydrolyzate is filtered, and then freeze-dried into keratin peptide powder.

[0067] Preparation of vinyl PEGylated keratin peptides:

[0068] 2 g of keratin peptide powder was dissolved in 5 ml of 50 mM phosphate solution, and the pH value of the resulting solution was adjusted to 8.5 to form a keratin peptide solution. Filter through a filter with a pore size of 0.2 microns. After adding 50 mg / ml of Acrl-PEG-SCM (MW2000) powder to the pH-adjusted keratin peptide solution, it was reacted at 4° C. in the dark for 3 hours. The Acrl-PEG-Keratin solution obtained after the reaction was separated with a gel chromatographic column. The molecular weight of Acrl-PEG-Keratin ...

Embodiment 3

[0069] Example 3 - Preparation of Vinyl Pegylated Keratin Peptides

[0070] Extraction of Keratin Peptides:

[0071] Take 60 grams of washed and dried wool and add it to 400ml of 0.5mol / L sodium hydroxide solution. React in a constant temperature water bath at 100°C for 24 hours. The obtained wool hydrolyzate is filtered, hydrochloric acid solution is dropped in the obtained filtrate to adjust the keratin peptide solution to neutrality while stirring, and then spray-dried to form keratin peptide powder.

[0072] Preparation of vinyl PEGylated keratin peptides:

[0073] Dissolve keratin peptide powder in 100mM HEPES solution until saturated. The pH of the resulting solution was adjusted to 7.5 by dropwise addition of 1 M sodium hydroxide solution. Filter through a filter with a pore size of 0.2 microns. After adding 100 mg / ml of Acrl-PEG-SVA (MW5000) powder to the pH-adjusted keratin peptide solution, react at room temperature in the dark for 2 hours. The Acrl-PEG-Keratin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com