Instrument cable for nuclear power station

A technology for instrument cables and nuclear power plants, applied in the field of cable applications, can solve the problems of general anti-radiation ability and general life, and achieve the effects of good immersion performance, good low-smoke halogen-free flame retardant performance, and good insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

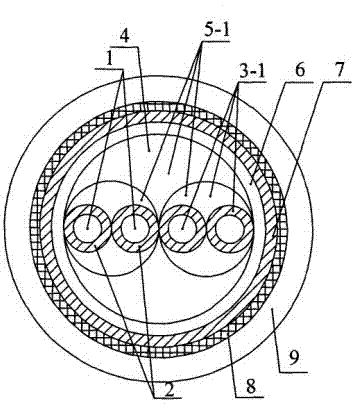

[0031] Such as figure 1 As shown, an instrumentation cable for nuclear power plants includes two core wires A3-1 and 4 twisted cores A5-1 filled with 4 pairs. Each core wire A3-1 is composed of two twisted conductors 1 with an insulating layer 2, and the insulating layer 2 is extruded on the conductor 1. A wrapping layer 6 , a copper-plastic composite tape 7 , a copper wire braiding layer 8 and a sheath 9 are provided in sequence outside the cable core A5-1. The cable core A5-1 is wrapped around the cladding layer 6, the copper-plastic composite tape 7 is wrapped around the cladding layer 6, and the copper wire braided layer 8 is extruded and wrapped with a sheath 9.

[0032] Wherein: conductor 1 adopts tinned copper wire twisted structure. Filling 4 is preferably a low-smoke, halogen-free, flame-retardant filling strip. The braided layer of copper wire 8 is preferably a braided layer of tinned copper wire. The insulating layer 2 is preferably a low-smoke, halogen-free, fl...

Embodiment 2

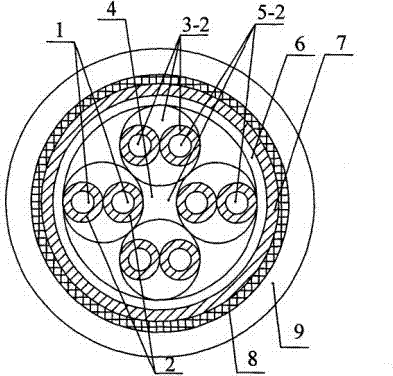

[0037] Such as figure 2 As shown, an instrumentation cable for nuclear power plants includes four core wires B3-2 and a filled 4-star twisted core B5-2. Each core wire B3-2 is composed of two twisted conductors 1 containing an insulating layer 2, and the insulating layer 2 is extruded on the conductor 1. A wrapping layer 6 , a copper-plastic composite tape 7 , a braided layer of copper wire 8 and a sheath 9 are provided on the outside of the cable core B5-2 in sequence. The cable core B5-2 is wrapped around the cladding layer 6, the copper-plastic composite tape 7 is wrapped around the cladding layer 6, and the sheath 9 is wrapped around the copper wire braided layer 8.

[0038] Wherein: conductor 1 adopts tinned copper wire twisted structure. Filling 4 is preferably a low-smoke, halogen-free, flame-retardant filling strip. The braided layer of copper wire 8 is preferably a braided layer of tinned copper wire. The insulating layer 2 is preferably a low-smoke, halogen-free...

Embodiment 3

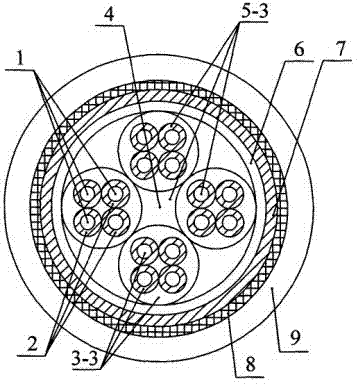

[0041] Such as image 3 As shown, an instrument cable for nuclear power plants includes four core wires C3-3 and a filled 4-star twisted core C5-3. Each core wire C3-3 is composed of four star-quad conductors 1 containing an insulating layer 2, and the insulating layer 2 is extruded on the conductors 1. A wrapping layer 6 , a copper-plastic composite tape 7 , a copper wire braiding layer 8 and a sheath 9 are provided in sequence outside the cable core C5-3. The cable core C5-3 is wrapped around the cladding layer 6, the copper-plastic composite tape 7 is wrapped around the cladding layer 6, and the copper wire braided layer 8 is extruded and wrapped with a sheath 9.

[0042] Wherein: conductor 1 adopts tinned copper wire twisted structure. Filling 4 is preferably a low-smoke, halogen-free, flame-retardant filling strip. The braided layer of copper wire 8 is preferably a braided layer of tinned copper wire. The insulating layer 2 is preferably a low-smoke, halogen-free, fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com