Preparation method for semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device preparation, can solve the problems of long corrosion time, low yield, perforation and fracture of battery sheets, etc., and achieve the effects of reducing production cost, shortening length, improving stripping yield and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

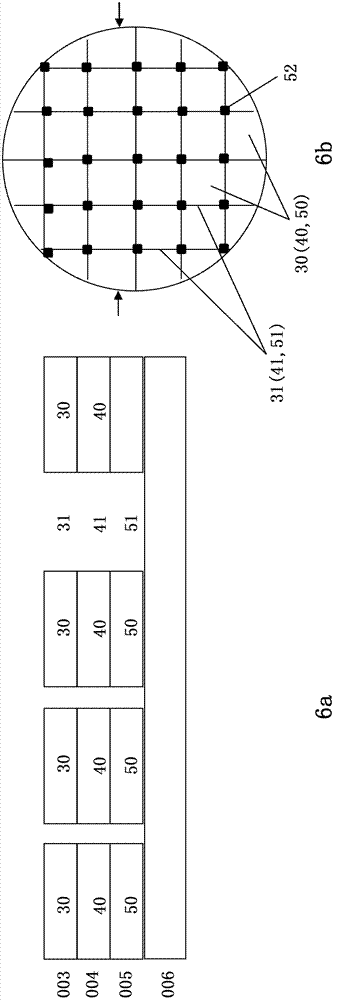

[0066] Refer to the attached figure 1 -8 Take gallium arsenide thin-film battery as an example to illustrate the process of preparing semiconductor devices of the present invention. Note that the drawings and the description of specific embodiments are only for better understanding of the present invention, and the present invention is not limited to the described embodiments.

[0067] The preparation process of the gallium arsenide thin film battery according to embodiment 1 is roughly as follows:

[0068] Step 1, preparing a battery functional layer on a gallium arsenide substrate, including:

[0069] Such as figure 1 As shown, prepare a gallium arsenide (GaAs) single crystal substrate 001 with a diameter of about 4 inches (10 cm) or more, and pass MOVPE (Metal-Orgainc Vapor Phase Epitaxy, organic Metal vapor phase epitaxy) or MBE (Molecular Beam Epitaxy, molecular beam epitaxy) grows a sacrificial layer 002 of aluminum arsenide (AlAs) or gallium aluminum arsenide (AlGaAs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com