Ball-milling coupling extraction integrated process for strengthening natural plant active ingredient extraction

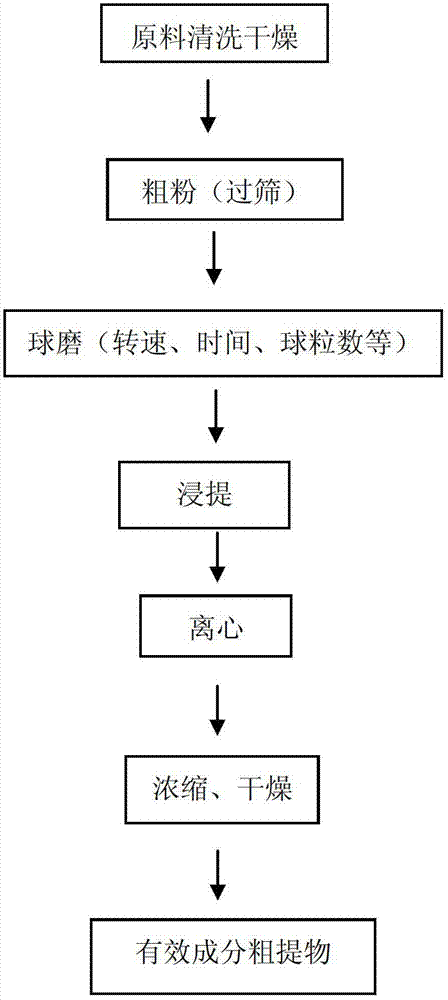

An active ingredient and process technology, which is applied in the integrated process field of ball milling coupled leaching to strengthen the extraction of natural active ingredients of plants, can solve the problem that the process needs to be further improved, and achieve the effects of strong free radical scavenging ability, convenient operation and improved extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Extraction Technology of Grape Skin Polyphenols by Ball Milling Method

[0028] Crush the grape pomace through a 40-mesh sieve, select the TJ-1 type particle ball mill, and then put it and the balls in a certain ratio (mass (g) / number) of 1:4, and place them in a ball mill made of zirconia. , the balls are zirconia balls, rotate ball mill at 1000rpm for 30min, then extract with 60% ethanol in 70℃ constant temperature water bath for 30min according to 1:10 solid-liquid ratio, centrifuge to get the supernatant, concentrate and dry to form the finished product. After concentrating under reduced pressure, the obtained ethanol is recycled for reuse. Using the Prussian blue method and using catechol as the standard, the polyphenols in grape skin were measured to be 17.90% higher than that of crushed grape pomace after leaching in a water bath at 70°C for 30 minutes. After removing DPPH free radicals and OH - Free radicals, O 2- Anti-oxidation experiments such as can be obta...

Embodiment 2

[0030] Ball Milling Extraction Technology of Scutellaria baicalensis

[0031] Crush Scutellaria baicalensis through a 20-mesh sieve, use a double planetary ball mill, put the material and the balls in a certain ratio (mass (g) / number) of 1:6, put them in an agate ball mill jar, use agate balls, and grind them at 1200rpm After rotating ball milling for 30 minutes, the obtained powder was leached with 65% ethanol in a constant temperature water bath at 70°C according to a ratio of 1:14 to liquid, centrifuged at 4000 rpm for 15 minutes after 60 minutes, and the supernatant was taken, concentrated and dried to form a finished product. After concentration under reduced pressure, the obtained ethanol is recovered and reused. Using sodium nitrite and aluminum nitrate colorimetric method, with rutin as the standard product, the content of baicalin flavonoids after ball milling was measured to increase by 21.97%, after removing DPPH free radicals, OH- free radicals, O 2- It can be obt...

Embodiment 3

[0033] Ball Milling Extraction Technology of Scutellaria Baicalensis Polysaccharides

[0034] 2. Scutellaria baicalensis processed products are crushed through a 20-mesh sieve, and an all-round planetary ball mill is selected, and then the material and the balls are placed in a stainless steel ball mill tank according to a certain ratio (mass (g) / number) of 1:2. , after ball milling at 1000rpm for 60min, weigh 2g of Scutellaria baicalensis processed product into a round bottom flask, add 40mL of water to extract at 70°C for 2h, filter, and take the supernatant. After alcohol precipitation, crude polysaccharides are obtained. Using the phenol-sulfuric acid method, with glucose as the standard product, the polysaccharide content of processed Scutellaria baicalensis after ball milling was measured to be 15.97% higher than that directly crushed and extracted. After removing DPPH free radicals, OH- free radicals, O 2- Anti-oxidation experiments show that the obtained polysaccharid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com