Waste PCB (printed circuit board) crushing and sorting system

A PCB board and sorting system technology, applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve the problems of resource waste, environmental hazards, etc., and achieve the effect of efficiently recycling resources and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

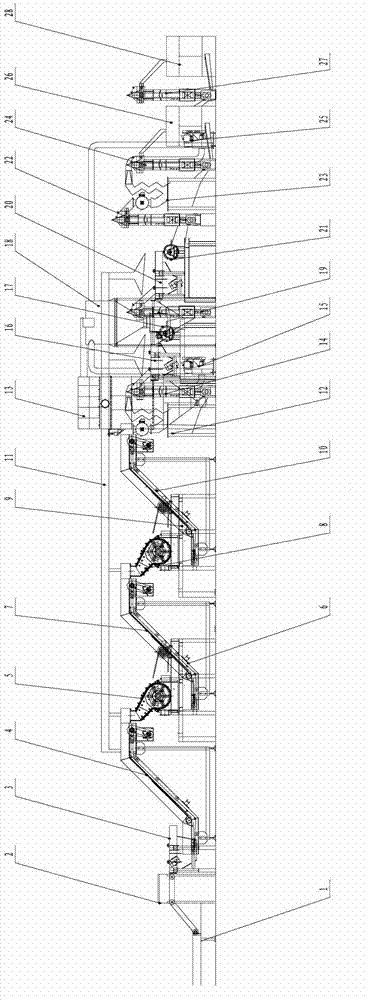

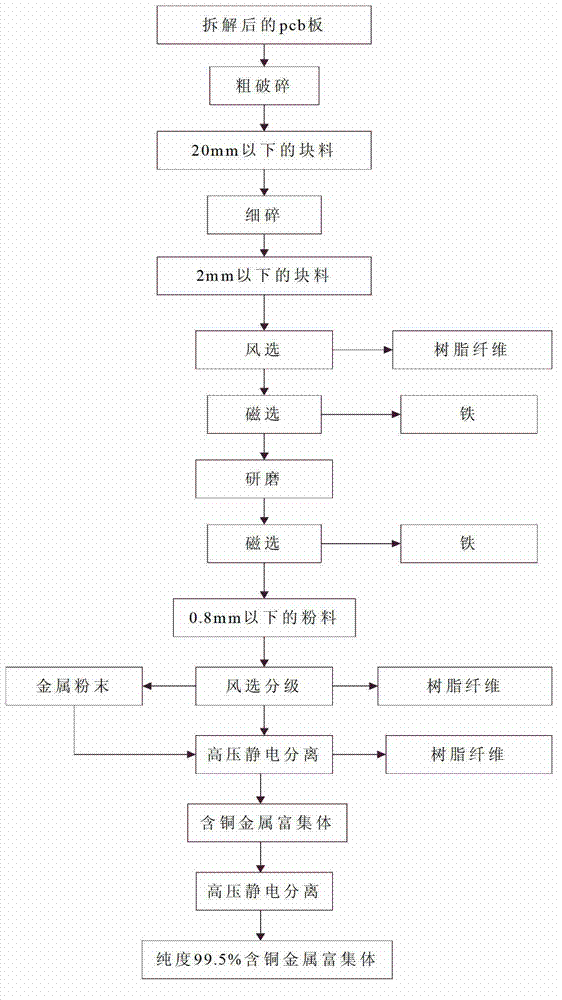

[0022] The waste and old PCB board crushing and sorting system of the present invention, its preferred embodiment is:

[0023] Including dismantling unit, crushing unit, primary air separation unit, iron removal unit, grinding unit, fine iron removal unit, wind separation separation unit, high-voltage electrostatic separation unit, dust waste gas treatment unit, and central control unit;

[0024] In the dismantling unit, electronic components containing precious metals on the circuit board and electronic components with a height greater than 30mm are removed;

[0025] In the crushing unit, the disassembled circuit board is crushed to particles with a particle size of less than 2mm through two-stage crushing;

[0026] The primary winnowing unit separates non-metallic particles from the crushed material;

[0027] The iron removal unit performs a primary iron removal on the material after the primary winnowing;

[0028] The grinding unit grinds and pulverizes the material after...

specific Embodiment

[0061] Specific examples, such as figure 1 , figure 2 Shown:

[0062] 1. Dismantling the unit

[0063] The circuit board is on the dismantling workbench, manually remove electronic components containing precious metals and other electronic components with a height greater than 30mm (such as sockets, transformers, coolers, I / O slots, CPU slots, etc.) , and classified storage.

[0064] The disassembled waste PCB board enters the automatic electronic component removal machine through the conveyor; the electronic component removal machine is composed of a chuck separation knife and a fan. The circuit board enters the body and is automatically clamped. Under the action of the separation knife The circuit board and electronic components are separated, and the dust and smoke generated during the separation process are extracted by the fan to avoid environmental pollution. The separated circuit board and electronic components are sent to the vibrating screen by the conveyor, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com