Continuous casting system capable of obtaining closed-cell foam aluminum with uniform bubble bodies

A technology of closed-cell aluminum foam and foam body, which is applied in casting equipment, casting molten material containers, manufacturing tools, etc. It can solve the problems of unsuitable foam aluminum material, high production cost, and difficult operation, etc., and achieve the uniformity of foam body Good, simple equipment manufacturing, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation method of the present invention is as follows: first melt the qualified melt in the smelting furnace, and transfer the melt to the tundish, then add tackifying particles into the tundish while stirring, and finally transfer the tackifying melt to the tundish. into the continuous foaming furnace for continuous casting. The present invention will be described in detail below in conjunction with the accompanying drawings.

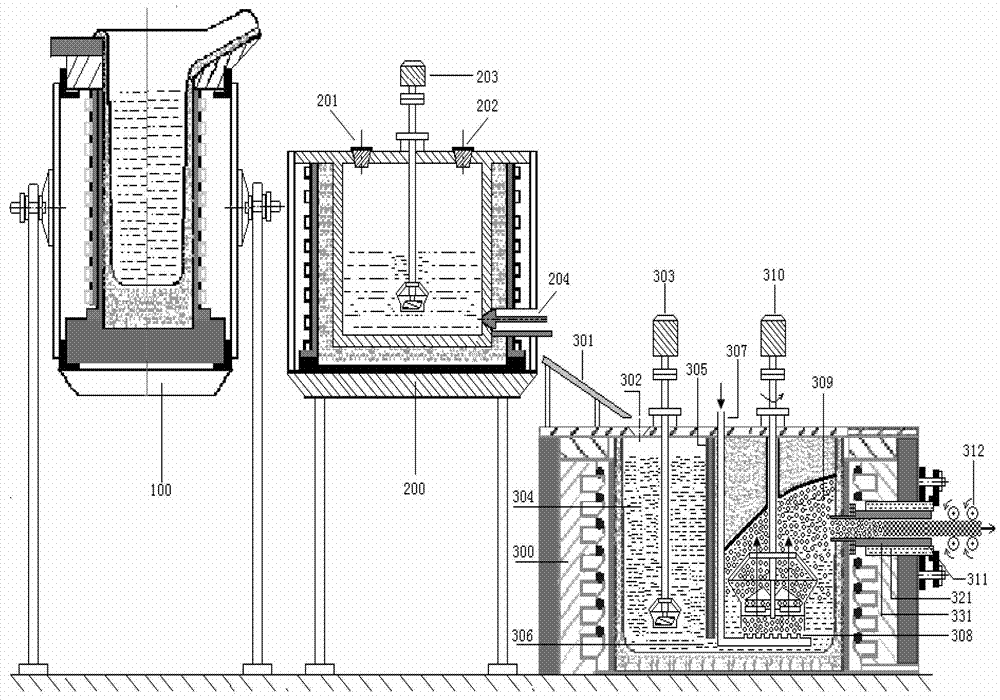

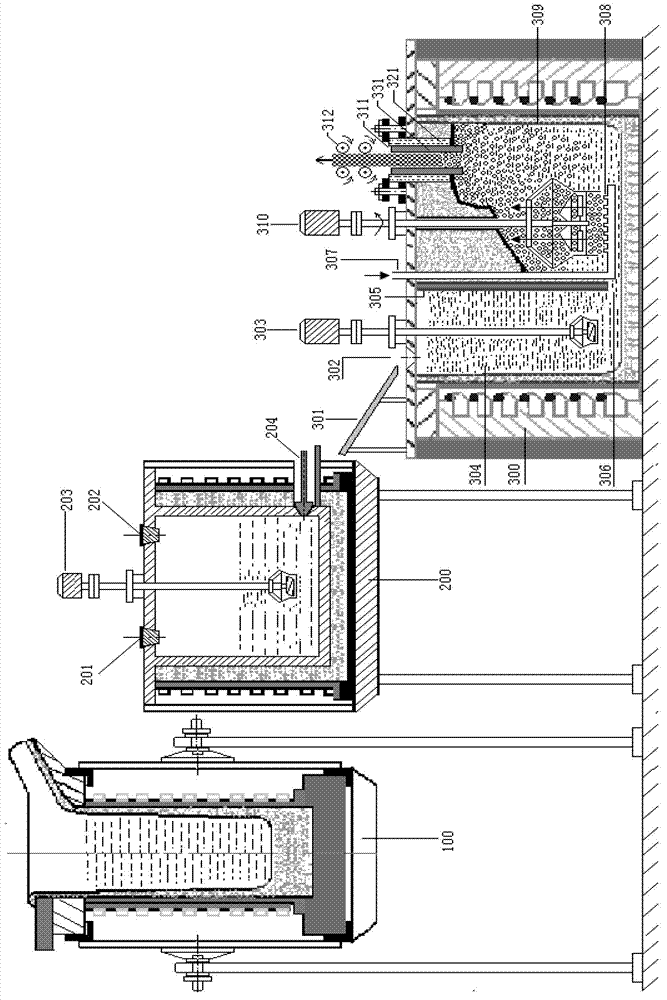

[0018] see figure 1 , a continuous casting system capable of obtaining uniform foam closed-cell aluminum foam, which is composed of a melting furnace 100, a tundish 200, a continuous foaming furnace 300, a continuous casting mold 311 and a continuous traction device 312. The tundish 200 is equipped with an anti-melting The agitator 203 for settling the viscosifying particles, the tundish 200 also has a melt inlet 201 for the melt of the melting furnace 100 to enter, a particle inlet 202 for adding the melt viscosifying parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com