Preparation method of N,N-dimethyl-N-fatty alcohol polyethenoxy ether-base carboxymethyl lycine

A technology of alcohol polyoxyethylene ether and carboxymethyl beet, which is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc., and can solve the problems of unavoidable toxicity, many process steps, and harmful environment and production equipment Hydrogen halide and other problems, to achieve the effect of excellent surfactant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

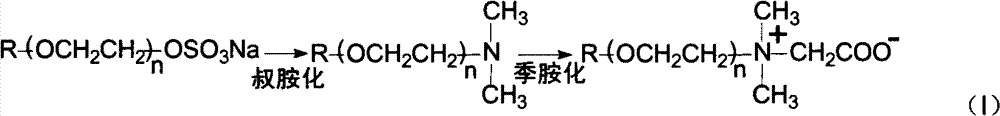

[0018] Example 1 Preparation of N,N-dimethyl-N-fatty alcohol polyoxyethylene ether carboxymethyl betaine

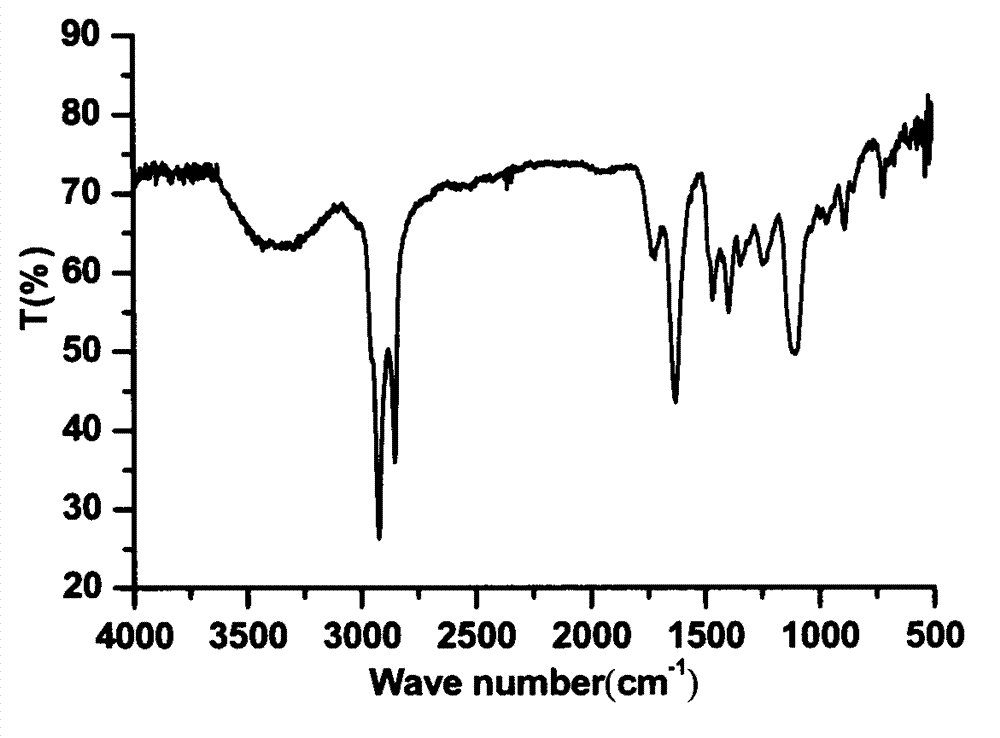

[0019] Take 35g of fatty alcohol polyoxyethylene ether (3) sulfate sodium salt AES, 35g of dimethylamine, and 25g of deionized water in a reactor, airtightly stir and heat to 145°C for 12 hours, then remove unreacted dimethylamine; After adding 6.25g of sodium chloroacetate and 23.75g of ethanol, adjust the pH of the system to 8 with sulfuric acid and control the reaction temperature to 70°C; keep the reaction for 8 hours to obtain the product N,N-dimethyl-N-fatty alcohol polyoxyethylene Ether Carboxymethyl Betaine 34.3g, its infrared spectrum is attached figure 1 Shown. 2960cm -1 , 2929cm -1 , 2854cm -1 Nearby is the C-H stretching vibration absorption peak of saturated alkane group, 1727cm -1 , 1630cm -1 Nearby is the C-O stretching vibration absorption peak of the carbonyl group, 1465cm -1 , 1395cm -1 Nearby is the C-H flexural vibration absorption peak of methyl and meth...

Embodiment 2

[0021] Example 2 Preparation of N,N-dimethyl-N-fatty alcohol polyoxyethylene ether carboxymethyl betaine

[0022] Take 250g of fatty alcohol polyoxyethylene ether (3) sulfate sodium salt AES, 250g parts of dimethylamine, and 250g of deionized water in the reactor, airtightly stir and heat to 185°C for 8 hours, then remove unreacted dimethylamine After adding 50g of potassium chloroacetate and 200g of ethanol, adjust the pH of the system to 10 with hydrochloric acid, and control the reaction temperature to 100℃; keep the reaction for 4 hours to obtain the product N,N-dimethyl-N-fatty alcohol polyoxyethylene ether 247g of carboxymethyl betaine.

Embodiment 3

[0023] Example 3 Preparation of N,N-dimethyl-N-fatty alcohol polyoxyethylene ether carboxymethyl betaine

[0024] Take 3kg of fatty alcohol polyoxyethylene ether (3) sulfate sodium salt AES, 3kg of dimethylamine, and 1.5kg of deionized water in the reactor, stir tightly and raise the temperature to 180°C for 10 hours, then remove unreacted dimethylamine After adding 1kg of sodium chloroacetate and 1.5kg of ethanol, adjust the pH of the system to 9.0 with phosphoric acid and control the reaction temperature to 85°C; keep the reaction for 6.5 hours to obtain the product N,N-dimethyl-N-fatty alcohol polyoxyethylene Ether carboxymethyl betaine 2.92 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com