Reinforced high heat resistance and conductivity polyphenyl ether nylon alloy and preparation method thereof

A polyphenylene ether, high heat-resistance technology is applied in the field of reinforced high-heat-resistance conductive polyphenylene ether nylon alloy and its preparation, and achieves the effects of good dimensional stability, optimized processing performance, and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

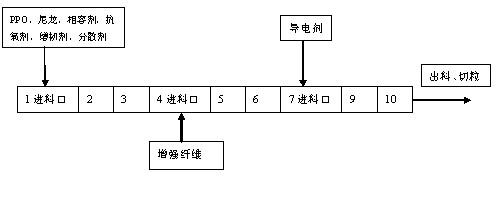

[0043] The preparation method comprises the following steps:

[0044] (1) Weigh raw materials according to weight ratio: polyphenylene ether 10-50%, nylon 10-40%, compatibilizer 5-15%, toughening agent 2-20%, dispersant 0.2-2%, antioxidant Add 0.2-0.6% of the agent, put it into the high mixer and mix for 2-5 minutes, and then add it from the first section of the twin-screw extruder;

[0045] (2) Add glass fiber with a weight ratio of 10-40% from the fourth section of the twin-screw extruder;

[0046] (3) The conductive agent with a weight ratio of 5-30% is added from the seventh barrel of the twin-screw extruder through side feeding;

[0047] (4) The above-mentioned materials are extruded and granulated by a twin-screw extruder, the rotation speed of the screw machine is 180-600 rpm, and the temperature is 245-275°C.

[0048] It should be noted that the specific viscosity of the polyphenylene ether (PPO) resin in chloroform at 25°C is 0.2-0.6 dl / g, preferably PPO LXR035 and ...

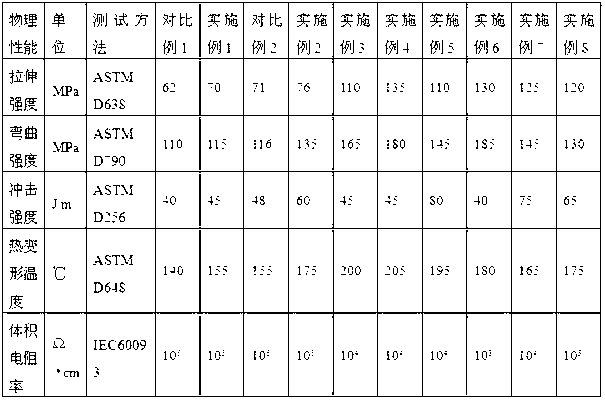

Embodiment 1

[0057] (1) Weigh raw materials according to weight ratio: PPO LXR045: 15%, PA66: 40%, polyphenylene ether-nylon compatibilizer (CMG-W-01): 5%, Karton G1651: 8.6%, dispersant: 1.0%, antioxidant: 0.4%, put into the high-mixer and mix for 5 minutes, then add from the first section of the cylinder of the twin-screw extruder;

[0058] (2) Add glass fiber with a weight ratio of 15% from the fourth barrel of the twin-screw extruder;

[0059] (3) Carbon black with a weight ratio of 15% is added from the seventh barrel of the twin-screw extruder through side feeding;

[0060] (4) The above-mentioned materials are extruded and granulated by a twin-screw extruder, the rotation speed of the screw machine is 500 rpm, and the temperature is 265°C.

Embodiment 2

[0062] (1) Weigh raw materials according to weight ratio: polyphenylene ether: 10%, PA1010: 33%, polyphenylene ether-nylon compatibilizer (CMG-W-01): 10%, Karton G1650: 10.7%, dispersant : 0.8%, Antioxidant: 0.5%, put it into the high mixer and mix for 5 minutes, and then add it from the first section of the twin-screw extruder;

[0063] (2) Add glass fiber with a weight ratio of 20% from the fourth section of the twin-screw extruder;

[0064] (3) Carbon black with a weight ratio of 15% is added from the seventh barrel of the twin-screw extruder through side feeding;

[0065] (4) The above-mentioned materials are extruded and granulated by a twin-screw extruder, the rotation speed of the screw machine is 600 rpm, and the temperature is 265°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com