Preparation method of high-purity diglyceride

A diglyceride, high-purity technology, applied in the field of preparation of high-purity diglyceride, can solve the problem of difficult separation of MAG, achieve the effect of simplifying the separation process, simplifying the separation process, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

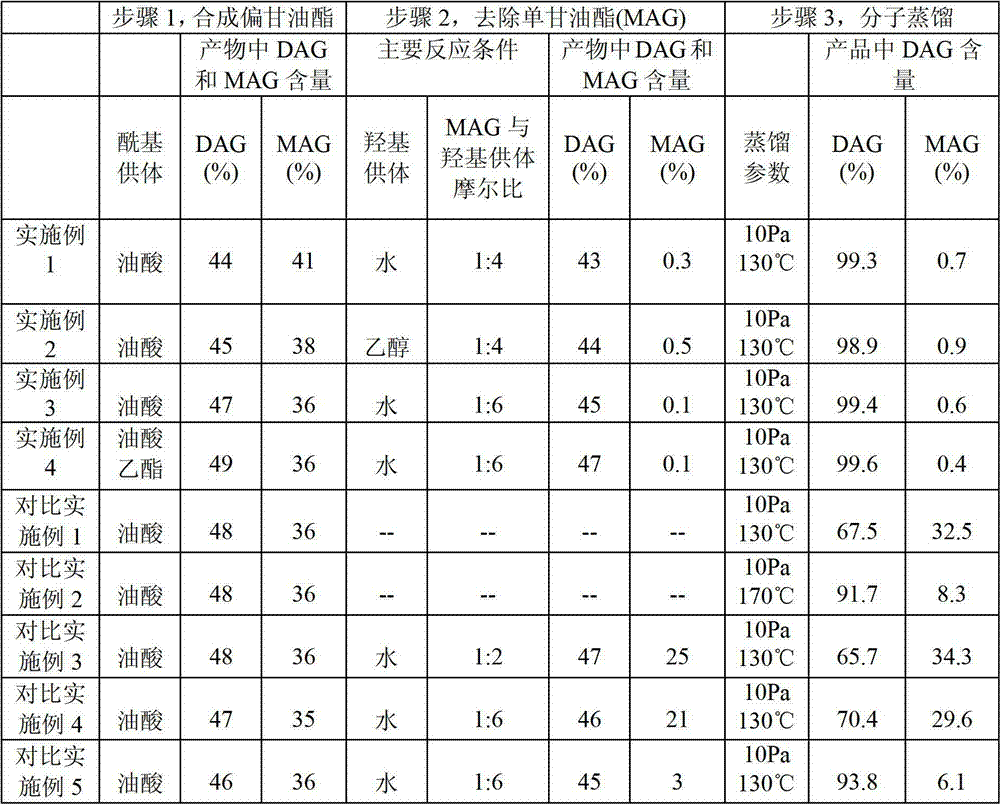

Examples

Embodiment 1

[0029] Take 285g oleic acid (fatty acid composition: 80% oleic acid, 10% linoleic acid, 2% stearic acid, 8% palmitic acid) and 184g glycerin (molar ratio is 1:2) and 4.7g distilled water , put into a stoppered Erlenmeyer flask and mix evenly, and place it on a constant temperature magnetic stirrer with a rotating speed of 400rpm to react, add partial glyceride lipase LipaseSMG1 based on the total mass of the reaction mixture of 240U / g, and control the reaction temperature to 25°C; After 24 hours, the esterification product mixture was centrifuged, and the upper oil phase was recovered. The product composition is shown in Table 1. To the recovered oil phase, add water that is 4 times the molar number of monoglyceride (MAG), based on the total mass of the reaction mixture 200U / g of monoglyceride lipase MGL, put it into a stoppered Erlenmeyer flask, mix evenly, and place React on a magnetic stirrer with a rotation speed of 400rpm, program cooling (the initial reaction temperature...

Embodiment 2

[0031]Take 285g oleic acid (fatty acid composition: 80% oleic acid, 10% linoleic acid, 2% stearic acid, 8% palmitic acid) and 368g glycerin (molar ratio is about 1:4) and 6.5g Distilled water was put into a stoppered Erlenmeyer flask, mixed evenly, and placed on a constant temperature magnetic stirrer with a rotation speed of 400rpm for reaction, and partial glyceride lipase LipaseG50 based on the total mass of the reaction mixture of 240U / g was added, and the reaction temperature was controlled at 25°C; After reacting for 24 hours, the esterification product mixture was centrifuged, and the upper oil phase was recovered. The product composition is shown in Table 1. Add dehydrated ethanol 4 times relative to the MAG molar number to the recovered oil phase, based on the monoglyceride lipase bMGL of 200U / g of the total mass of the reaction mixture, put it into a stoppered Erlenmeyer flask and mix evenly, and place at a speed of The reaction was performed on a magnetic stirrer at...

Embodiment 3

[0033] Take 285g oleic acid (fatty acid composition: 80% oleic acid, 10% linoleic acid, 2% stearic acid, 8% palmitic acid) and 368g glycerin (molar ratio is about 1:4) and 6.5g Distilled water was put into a stoppered Erlenmeyer flask, mixed evenly, and placed on a constant temperature magnetic stirrer with a rotation speed of 400rpm for reaction, and partial glyceride lipase LipaseSMG1 based on the total mass of the reaction mixture of 240U / g was added, and the reaction temperature was controlled at 25°C; After reacting for 24 hours, the esterification product mixture was centrifuged, and the upper oil phase was recovered. The product composition is shown in Table 1. Add 6 times the water relative to the MAG mole number to the recovered oil phase, based on the monoglyceride lipase bMGL of 200U / g of the total mass of the reaction mixture, put it into a stoppered Erlenmeyer flask and mix it evenly, and place it in a rotating speed of 400rpm React on a magnetic stirrer, program ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com